Dacron polyester is renowned for its exceptional durability and resistance to stretching, making it ideal for applications requiring long-lasting performance and dimensional stability. Vectran polyester offers superior tensile strength and flexibility, excelling in high-stress environments where lightweight and high-performance materials are crucial. Choosing between Dacron and Vectran polyester depends on balancing strength, elasticity, and application-specific demands.

Table of Comparison

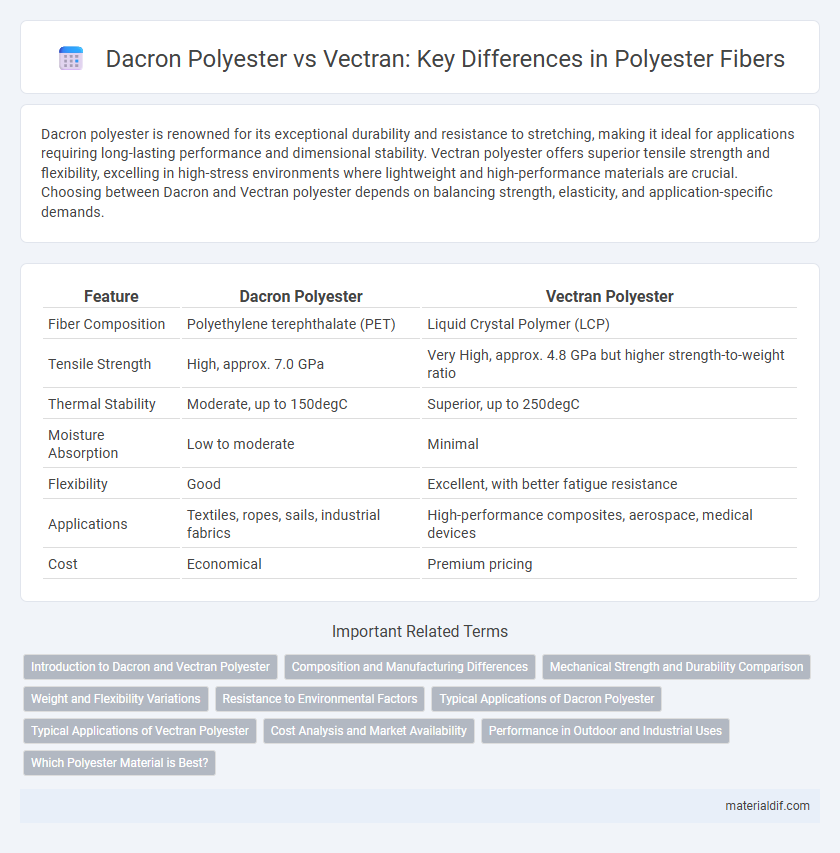

| Feature | Dacron Polyester | Vectran Polyester |

|---|---|---|

| Fiber Composition | Polyethylene terephthalate (PET) | Liquid Crystal Polymer (LCP) |

| Tensile Strength | High, approx. 7.0 GPa | Very High, approx. 4.8 GPa but higher strength-to-weight ratio |

| Thermal Stability | Moderate, up to 150degC | Superior, up to 250degC |

| Moisture Absorption | Low to moderate | Minimal |

| Flexibility | Good | Excellent, with better fatigue resistance |

| Applications | Textiles, ropes, sails, industrial fabrics | High-performance composites, aerospace, medical devices |

| Cost | Economical | Premium pricing |

Introduction to Dacron and Vectran Polyester

Dacron polyester, a widely used polyester fiber developed by DuPont, is known for its excellent tensile strength, wrinkle resistance, and durability, making it ideal for textiles and industrial applications. Vectran polyester, a high-performance liquid crystal polymer fiber, offers superior strength, moisture resistance, and dimensional stability, often used in aerospace, military, and composite materials. Both fibers feature unique chemical structures that optimize performance for specific technical and commercial uses, with Dacron focusing on versatility and Vectran excelling in high-stress environments.

Composition and Manufacturing Differences

Dacron polyester is primarily composed of polyethylene terephthalate (PET) and is produced through melt spinning, resulting in durable and versatile fibers commonly used in textiles and industrial applications. In contrast, Vectran polyester is a liquid crystal polymer (LCP) fiber manufactured using a gel-spinning process, which imparts exceptional strength, high tensile modulus, and superior dimensional stability. These fundamental differences in chemical composition and manufacturing techniques enable Vectran to outperform Dacron in high-performance uses such as aerospace and protective gear.

Mechanical Strength and Durability Comparison

Dacron polyester is renowned for its high tensile strength and excellent resistance to stretching, making it ideal for applications requiring long-term durability and dimensional stability. Vectran polyester, a liquid crystal polymer fiber, surpasses Dacron in mechanical strength with superior tensile modulus and impact resistance, offering enhanced performance in abrasion and fatigue resistance. While Dacron excels in cost-effectiveness and UV resistance, Vectran provides advanced mechanical durability for high-performance aerospace and industrial uses.

Weight and Flexibility Variations

Dacron polyester is known for its lightweight properties, typically weighing less than Vectran polyester, which contributes to its widespread use in fabrics and sails where reduced weight is crucial. Vectran polyester offers superior flexibility and higher tensile strength compared to Dacron, making it ideal for applications requiring enhanced durability and stretch resistance. The weight variation between these fibers directly impacts performance, with Dacron favoring lightweight applications and Vectran excelling in flexible, high-stress environments.

Resistance to Environmental Factors

Dacron polyester exhibits exceptional resistance to UV radiation, moisture, and chemicals, making it highly durable for outdoor and industrial applications. Vectran polyester offers superior resistance to abrasion and impact while maintaining excellent dimensional stability under extreme environmental conditions. Both fibers provide robust environmental resistance, but Vectran is preferred when high-performance durability and strength against mechanical stress are critical.

Typical Applications of Dacron Polyester

Dacron polyester is commonly used in industrial applications such as tire reinforcements, conveyor belts, and protective clothing due to its high strength and durability. It also finds extensive use in textiles, including upholstery, sails, and apparel, benefiting from its wrinkle resistance and color retention properties. Dacron polyester's versatility and reliability make it preferred for manufacturing durable, long-lasting products in both commercial and consumer markets.

Typical Applications of Vectran Polyester

Vectran polyester is widely used in high-performance applications such as aerospace components, sporting goods, and protective gear due to its exceptional strength and lightweight properties. It is favored for ropes, cables, and body armor where superior durability and cut resistance are critical. Unlike Dacron polyester, Vectran excels in environments requiring thermal stability and chemical resistance.

Cost Analysis and Market Availability

Dacron polyester is widely recognized for its cost-effectiveness, offering a lower price point compared to Vectran polyester, making it a preferred choice in budget-sensitive applications. Vectran polyester, although significantly more expensive due to its superior strength and durability, caters to niche markets such as aerospace and high-performance sports equipment where material performance justifies the higher cost. Market availability of Dacron is extensive with broad distribution channels, whereas Vectran's availability is limited due to specialized production and targeted industrial use.

Performance in Outdoor and Industrial Uses

Dacron polyester offers exceptional durability, UV resistance, and dimensional stability, making it ideal for outdoor applications like sails, tents, and industrial filters. Vectran polyester provides superior tensile strength, impact resistance, and flexibility, which excels in high-performance gear such as ropes, cables, and protective equipment. Both fibers serve distinct roles in demanding environments, with Dacron optimized for long-term exposure and Vectran engineered for critical load-bearing uses.

Which Polyester Material is Best?

Dacron polyester is renowned for its excellent durability, UV resistance, and cost-effectiveness, making it ideal for general-purpose applications like sails and outdoor fabrics. Vectran polyester offers superior strength, low stretch, and exceptional abrasion resistance, often preferred in high-performance uses such as aerospace and advanced sporting goods. The best polyester material depends on the specific requirements: Dacron suits everyday durability and affordability, while Vectran excels in strength-critical, high-stress environments.

Dacron Polyester vs Vectran Polyester Infographic

materialdif.com

materialdif.com