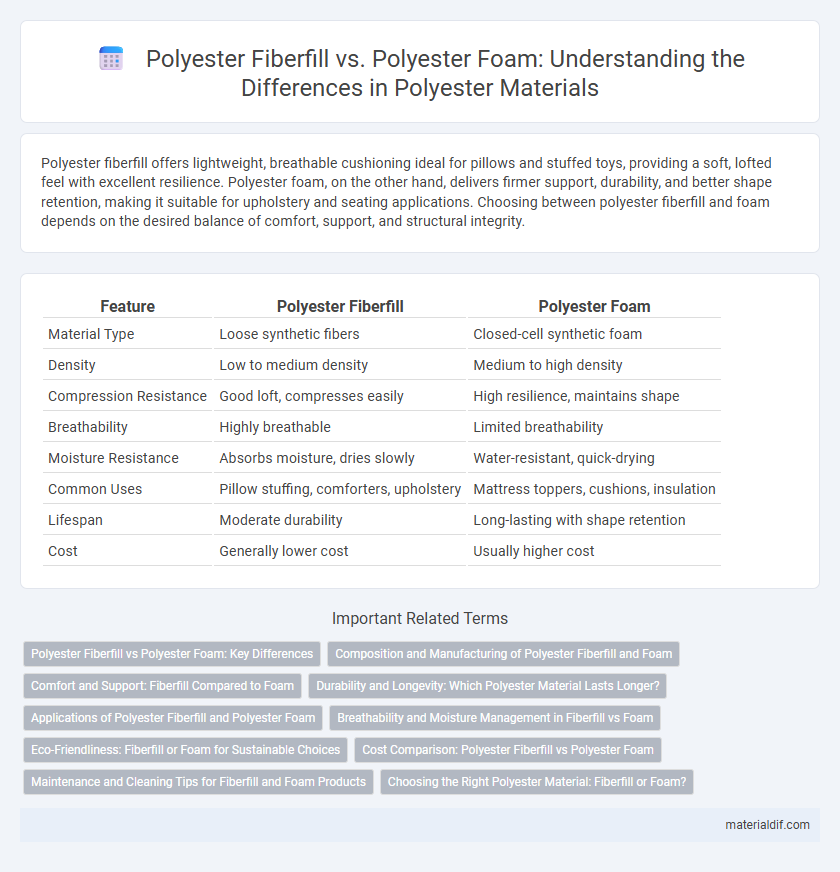

Polyester fiberfill offers lightweight, breathable cushioning ideal for pillows and stuffed toys, providing a soft, lofted feel with excellent resilience. Polyester foam, on the other hand, delivers firmer support, durability, and better shape retention, making it suitable for upholstery and seating applications. Choosing between polyester fiberfill and foam depends on the desired balance of comfort, support, and structural integrity.

Table of Comparison

| Feature | Polyester Fiberfill | Polyester Foam |

|---|---|---|

| Material Type | Loose synthetic fibers | Closed-cell synthetic foam |

| Density | Low to medium density | Medium to high density |

| Compression Resistance | Good loft, compresses easily | High resilience, maintains shape |

| Breathability | Highly breathable | Limited breathability |

| Moisture Resistance | Absorbs moisture, dries slowly | Water-resistant, quick-drying |

| Common Uses | Pillow stuffing, comforters, upholstery | Mattress toppers, cushions, insulation |

| Lifespan | Moderate durability | Long-lasting with shape retention |

| Cost | Generally lower cost | Usually higher cost |

Polyester Fiberfill vs Polyester Foam: Key Differences

Polyester fiberfill consists of fine, fluffy synthetic fibers primarily used as stuffing in pillows, cushions, and soft toys for its lightweight and breathable properties. Polyester foam, however, is a solid, spongy material made through a chemical foaming process, offering greater durability, support, and shock absorption in mattresses and upholstery. Key differences lie in texture, density, and applications: fiberfill provides softness and loft, while foam delivers structural support and resilience in various cushioning products.

Composition and Manufacturing of Polyester Fiberfill and Foam

Polyester fiberfill is composed of continuous or staple synthetic fibers made from polyethylene terephthalate (PET) through a melt-spinning process, where molten polymer is extruded and stretched into fine filaments. Polyester foam, on the other hand, is produced by chemically foaming polyester resin, creating a cellular structure through gas expansion within the polymer matrix during polymerization or curing. The manufacturing of fiberfill emphasizes fiber crimping and consolidation for loft and resilience, while foam production focuses on controlling cell size and density to optimize cushioning and insulation properties.

Comfort and Support: Fiberfill Compared to Foam

Polyester fiberfill provides a soft, fluffy comfort that conforms gently to the body, making it ideal for pillows, cushions, and upholstery where a plush feel is desired. In contrast, polyester foam offers firmer support and better resilience, maintaining shape over time and providing structured cushioning for mattresses and seating. While fiberfill excels in softness and breathability, polyester foam is preferred for its durability and consistent support under pressure.

Durability and Longevity: Which Polyester Material Lasts Longer?

Polyester fiberfill offers superior resilience and maintains loft over time, making it highly durable for cushioning and insulation applications. Polyester foam tends to compress and degrade faster under continuous pressure, reducing its longevity in high-use environments. For extended durability and sustained performance, polyester fiberfill generally outlasts polyester foam.

Applications of Polyester Fiberfill and Polyester Foam

Polyester fiberfill is widely used in applications requiring lightweight insulation and cushioning, such as in pillows, comforters, upholstered furniture, and stuffed toys due to its softness, loft, and resilience. Polyester foam, on the other hand, excels in providing structural support and shock absorption, making it ideal for mattresses, automotive seating, packaging materials, and soundproofing products. Both materials leverage polyester's durability and moisture resistance but serve distinct purposes based on their physical forms and performance characteristics.

Breathability and Moisture Management in Fiberfill vs Foam

Polyester fiberfill offers superior breathability compared to polyester foam due to its loose, fibrous structure that allows better air circulation and moisture wicking. This fiberfill effectively manages humidity by trapping and dispersing moisture away from the body, enhancing comfort in textiles and bedding applications. In contrast, polyester foam tends to retain heat and moisture, making it less efficient in moisture management and breathability for active or humid environments.

Eco-Friendliness: Fiberfill or Foam for Sustainable Choices

Polyester fiberfill, often made from recycled PET bottles, offers a more eco-friendly option compared to polyester foam, which is typically petroleum-based and less biodegradable. Fiberfill's recyclability and lower environmental impact in production make it a preferred sustainable choice for insulation and cushioning. In contrast, polyester foam's longer degradation time and harmful chemical components present challenges for environmentally conscious consumers.

Cost Comparison: Polyester Fiberfill vs Polyester Foam

Polyester fiberfill generally costs less than polyester foam, making it a more budget-friendly option for stuffing pillows and cushions. Polyester foam typically has a higher price due to its denser structure and enhanced durability, which provides better support and longevity. When selecting between polyester fiberfill and polyester foam, cost-efficiency must be balanced with the intended use and comfort requirements.

Maintenance and Cleaning Tips for Fiberfill and Foam Products

Polyester fiberfill requires gentle washing with mild detergent and air drying to maintain its loft and prevent clumping, while polyester foam should be spot cleaned with a damp cloth and allowed to air dry to avoid water absorption and mold growth. Avoid high heat and bleach for both materials to extend product lifespan and retain structural integrity. Regular fluffing of fiberfill cushions and vacuuming of foam surfaces help remove dust and maintain optimal hygiene.

Choosing the Right Polyester Material: Fiberfill or Foam?

Polyester fiberfill offers lightweight, breathable cushioning ideal for pillows, stuffed toys, and insulation, while polyester foam provides denser, more durable support suited for upholstery and mattress applications. Selecting the right polyester material depends on desired firmness, resilience, and intended use--fiberfill excels in softness and loft, whereas foam delivers structured comfort and shock absorption. Understanding these properties ensures optimal performance and longevity in textile and furniture products.

Polyester Fiberfill vs Polyester Foam Infographic

materialdif.com

materialdif.com