Polyester twill features a diagonal weave that provides durability and resistance to wrinkles, making it ideal for workwear and uniforms. In contrast, polyester poplin has a smooth, tight weave offering a lightweight, breathable fabric perfect for shirts and blouses. Choosing between polyester twill and poplin depends on the desired balance of strength and comfort in the final garment.

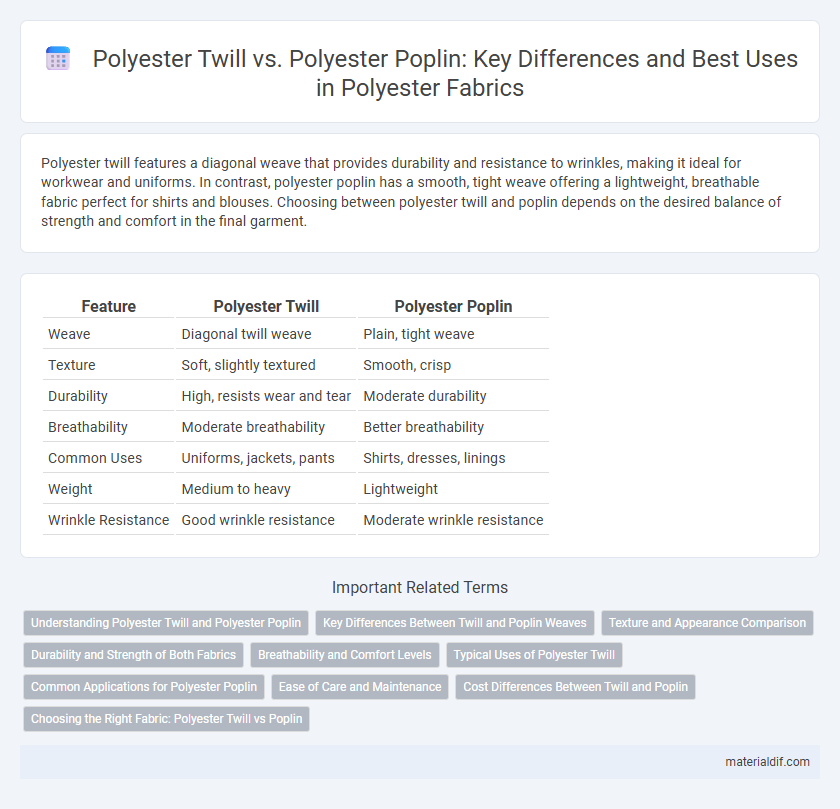

Table of Comparison

| Feature | Polyester Twill | Polyester Poplin |

|---|---|---|

| Weave | Diagonal twill weave | Plain, tight weave |

| Texture | Soft, slightly textured | Smooth, crisp |

| Durability | High, resists wear and tear | Moderate durability |

| Breathability | Moderate breathability | Better breathability |

| Common Uses | Uniforms, jackets, pants | Shirts, dresses, linings |

| Weight | Medium to heavy | Lightweight |

| Wrinkle Resistance | Good wrinkle resistance | Moderate wrinkle resistance |

Understanding Polyester Twill and Polyester Poplin

Polyester twill features a distinctive diagonal weave that enhances durability and wrinkle resistance, making it ideal for workwear and outerwear. Polyester poplin exhibits a smooth, plain weave that provides a lightweight, breathable fabric perfect for shirts and dresses. Both fabrics offer the strength and moisture-wicking properties of polyester but differ in texture, weight, and typical applications.

Key Differences Between Twill and Poplin Weaves

Polyester twill features a diagonal weave pattern that enhances durability and offers a textured surface, while polyester poplin has a tighter, plain weave that produces a smooth and lighter fabric ideal for breathable garments. Twill's distinctive diagonal lines contribute to higher wrinkle resistance and heavier weight compared to poplin's crisp, fine ribbed texture that excels in breathability and softness. These structural differences significantly influence their applications, with twill preferred for workwear and outerwear, and poplin favored for shirts and lightweight apparel.

Texture and Appearance Comparison

Polyester twill features a distinctive diagonal weave pattern that creates a textured surface with a subtle sheen, offering durability and a slightly heavier feel compared to polyester poplin. Polyester poplin is characterized by a smooth, tightly woven plain weave that results in a crisp, lightweight fabric with a matte finish and minimal texture. The textured appearance of polyester twill makes it suitable for outerwear and workwear, while the sleek surface of polyester poplin is preferred for dress shirts and blouses.

Durability and Strength of Both Fabrics

Polyester twill features a diagonal weave pattern that enhances its durability and strength, making it highly resistant to wear and tear compared to polyester poplin. Polyester poplin, with a tighter and smoother plain weave, offers moderate strength but lacks the robustness of twill, making it less suitable for heavy-duty applications. The superior durability of polyester twill makes it ideal for workwear and outdoor gear, whereas polyester poplin is better suited for lightweight garments and casual wear.

Breathability and Comfort Levels

Polyester twill features a diagonally woven structure that enhances durability but reduces breathability compared to polyester poplin, which has a plain weave allowing better air circulation and moisture management. The tighter weave of twill makes it more resistant to wrinkles and abrasion, contributing to increased comfort during physical activities in cooler climates. Polyester poplin's lightweight and smoother texture provides superior comfort in warm weather by promoting ventilation and reducing heat retention.

Typical Uses of Polyester Twill

Polyester twill is commonly used for durable garments such as workwear, uniforms, and outerwear due to its distinctive diagonal weave, which provides enhanced strength and resistance to wear and tear. This fabric's heavier weight and texture make it ideal for items requiring longevity and structure, including trousers, jackets, and upholstery. Unlike the smoother and lighter polyester poplin, polyester twill's robust construction supports applications where durability and wrinkle resistance are critical.

Common Applications for Polyester Poplin

Polyester Poplin is widely used in making lightweight garments such as shirts, blouses, and dresses due to its smooth texture and breathable fabric properties. Its tight weave provides durability, making it ideal for uniforms, workwear, and promotional apparel. The fabric's resistance to wrinkles and ease of printing also make Polyester Poplin popular in customized clothing and accessories.

Ease of Care and Maintenance

Polyester Twill offers enhanced durability and wrinkle resistance, making it easier to care for compared to other fabrics. Polyester Poplin features a smoother, lightweight texture but may require more frequent ironing to maintain its crisp appearance. Both fabrics are machine washable and resistant to shrinking, yet Twill's tighter weave generally requires less maintenance over time.

Cost Differences Between Twill and Poplin

Polyester twill generally costs more than polyester poplin due to its denser weave and increased durability, which require more material and manufacturing time. Poplin's lighter, plain weave structure results in lower production costs, making it a more budget-friendly option for projects where heavy fabric strength is not essential. Price variations also depend on factors like fabric weight, finish, and brand, but twill consistently remains the pricier choice for applications demanding longevity and thickness.

Choosing the Right Fabric: Polyester Twill vs Poplin

Polyester twill offers a durable, diagonal weave ideal for heavyweight applications like workwear and upholstery, providing excellent wrinkle resistance and a textured finish. Polyester poplin features a lightweight, plain weave with a smooth surface, making it suitable for shirts, dress fabrics, and linings that require breathability and a crisp appearance. Selecting between polyester twill and poplin depends on the desired fabric weight, texture, and end-use functionality such as durability versus softness.

Polyester Twill vs Polyester Poplin Infographic

materialdif.com

materialdif.com