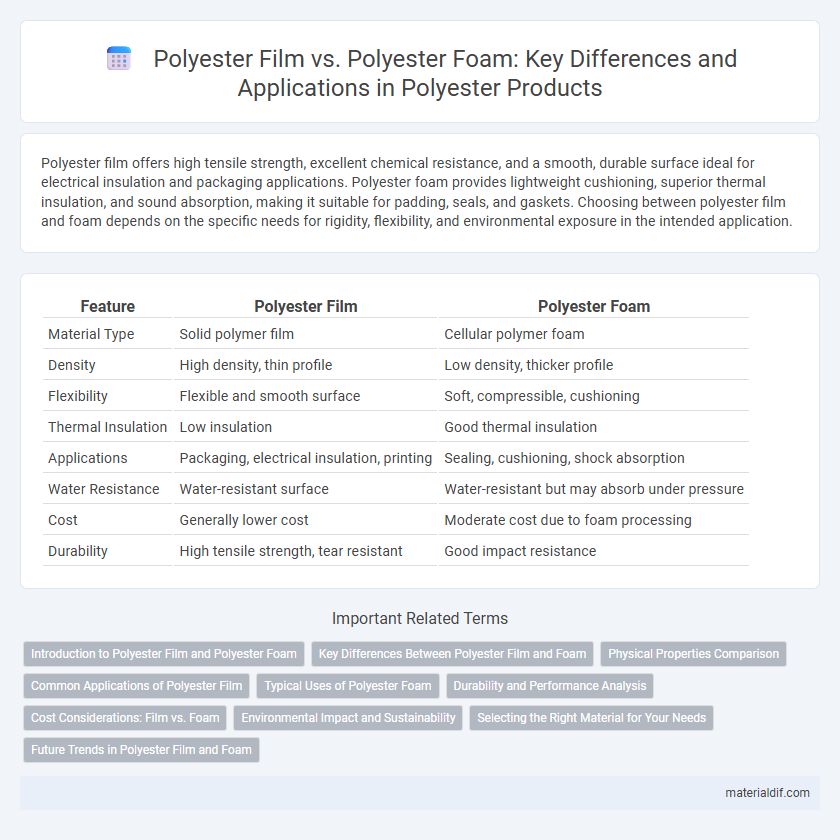

Polyester film offers high tensile strength, excellent chemical resistance, and a smooth, durable surface ideal for electrical insulation and packaging applications. Polyester foam provides lightweight cushioning, superior thermal insulation, and sound absorption, making it suitable for padding, seals, and gaskets. Choosing between polyester film and foam depends on the specific needs for rigidity, flexibility, and environmental exposure in the intended application.

Table of Comparison

| Feature | Polyester Film | Polyester Foam |

|---|---|---|

| Material Type | Solid polymer film | Cellular polymer foam |

| Density | High density, thin profile | Low density, thicker profile |

| Flexibility | Flexible and smooth surface | Soft, compressible, cushioning |

| Thermal Insulation | Low insulation | Good thermal insulation |

| Applications | Packaging, electrical insulation, printing | Sealing, cushioning, shock absorption |

| Water Resistance | Water-resistant surface | Water-resistant but may absorb under pressure |

| Cost | Generally lower cost | Moderate cost due to foam processing |

| Durability | High tensile strength, tear resistant | Good impact resistance |

Introduction to Polyester Film and Polyester Foam

Polyester film is a thin, durable plastic film made from stretched polyethylene terephthalate (PET), known for its excellent electrical insulation, chemical resistance, and dimensional stability. Polyester foam, in contrast, is a lightweight, porous material produced by foaming polyester resin, offering cushioning, sound absorption, and thermal insulation properties. Both materials serve diverse applications, with film commonly used in packaging and electronics, while foam is favored in upholstery and automotive components.

Key Differences Between Polyester Film and Foam

Polyester film is a thin, flexible sheet primarily used for packaging, insulation, and graphic applications due to its high tensile strength, chemical resistance, and clarity. In contrast, polyester foam is a lightweight, porous material commonly utilized for cushioning, soundproofing, and thermal insulation, benefiting from its compressibility and shock absorption properties. The key differences lie in their physical form, mechanical properties, and typical applications, with film offering durability and smoothness, while foam provides cushioning and impact resistance.

Physical Properties Comparison

Polyester film exhibits high tensile strength, excellent dimensional stability, and superior clarity, making it ideal for applications requiring durability and transparency. Polyester foam offers lightweight cushioning, good thermal insulation, and compressibility, which are essential for impact absorption and comfort. While polyester film excels in mechanical strength and resistance to moisture, polyester foam provides better shock absorption and flexibility due to its cellular structure.

Common Applications of Polyester Film

Polyester film is widely used in packaging, electrical insulation, and graphics due to its durability, clarity, and resistance to moisture and chemicals. It serves as a key component in magnetic tapes, capacitors, and solar panel back sheets, offering excellent dimensional stability and dielectric properties. Unlike polyester foam, which is predominantly utilized for cushioning and thermal insulation, polyester film excels in applications requiring precision and high-performance barrier characteristics.

Typical Uses of Polyester Foam

Polyester foam is widely used in automotive interiors, cushioning, and sound insulation due to its excellent padding and acoustic properties. It serves as a key material in furniture manufacturing for comfort and durability, as well as in packaging to protect delicate items during shipping. The foam's lightweight and resilient characteristics also make it ideal for filtration systems and thermal insulation applications.

Durability and Performance Analysis

Polyester film exhibits superior durability due to its high tensile strength, chemical resistance, and resistance to moisture, making it ideal for applications requiring long-term performance. In contrast, polyester foam offers enhanced shock absorption and insulation properties but may degrade faster under mechanical stress and environmental exposure. Performance analysis shows polyester film excels in protective coatings and electrical insulation, while polyester foam is preferred in cushioning and thermal insulation tasks.

Cost Considerations: Film vs. Foam

Polyester film typically incurs higher raw material costs compared to polyester foam due to its manufacturing process and specialized applications in electronics and packaging. Polyester foam offers a cost-effective alternative with lower production expenses and increased bulk, making it favorable for cushioning and insulation uses. Evaluating project requirements alongside budget constraints helps determine whether the premium quality of film justifies its elevated price over economical foam options.

Environmental Impact and Sustainability

Polyester film demonstrates higher recyclability and lower environmental impact compared to polyester foam, which often contains chemical additives that hinder biodegradability. The production of polyester film typically involves less energy consumption and emits fewer greenhouse gases than polyester foam manufacturing. Choosing polyester film supports sustainability goals by enabling easier material recovery and reducing landfill waste.

Selecting the Right Material for Your Needs

Polyester film offers superior tensile strength, chemical resistance, and dimensional stability, making it ideal for applications requiring durability and clarity, such as packaging and electrical insulation. Polyester foam provides enhanced cushioning, thermal insulation, and sound absorption, suited for comfort-focused uses like furniture padding and acoustic panels. Choosing between polyester film and foam depends on specific requirements for strength, flexibility, and insulation in your project.

Future Trends in Polyester Film and Foam

Future trends in polyester film emphasize enhanced durability, increased transparency, and improved thermal resistance for applications in flexible electronics and solar panels. Innovations in polyester foam focus on lightweight, high insulation properties combined with sustainability through bio-based or recycled materials. Advancements in both polyester film and foam aim to meet growing demands in automotive, packaging, and electronics industries with eco-friendly and high-performance solutions.

Polyester Film vs Polyester Foam Infographic

materialdif.com

materialdif.com