Dye sublimation on polyester produces vibrant, long-lasting colors by infusing ink directly into the fabric fibers, ensuring excellent durability and a soft feel without cracking or peeling. Screen printing on polyester typically uses plastisol or water-based inks that sit on top of the fabric, offering bold colors but can result in a heavier feel and possible cracking over time. Dye sublimation is ideal for complex, full-color designs on light-colored polyester, while screen printing works well for simpler designs and darker fabrics.

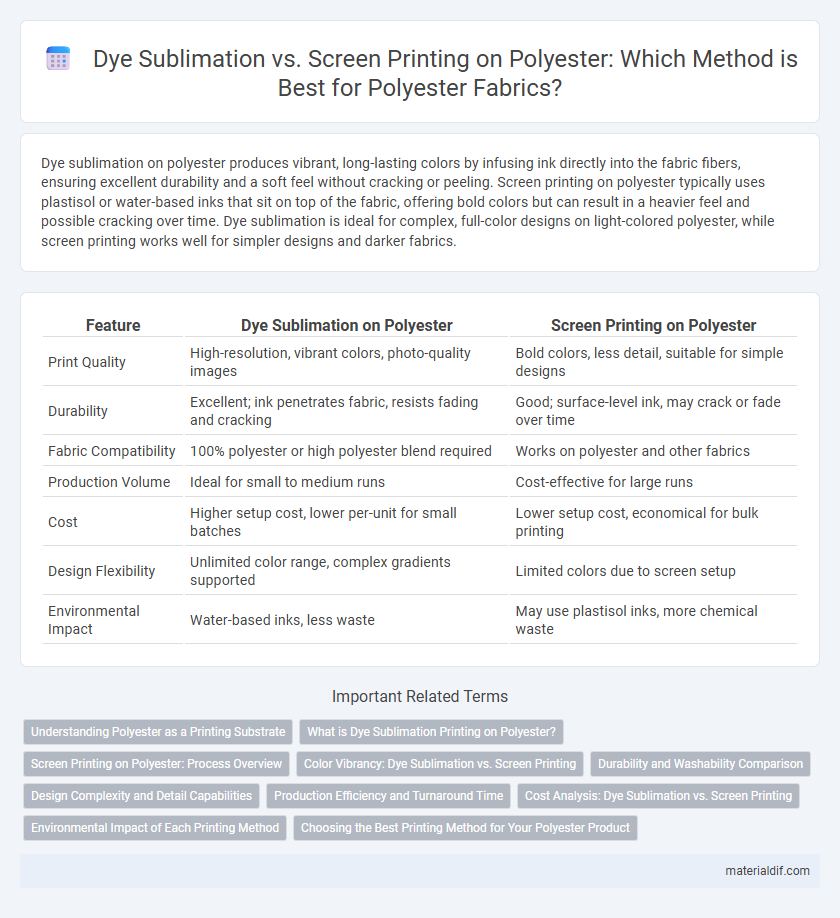

Table of Comparison

| Feature | Dye Sublimation on Polyester | Screen Printing on Polyester |

|---|---|---|

| Print Quality | High-resolution, vibrant colors, photo-quality images | Bold colors, less detail, suitable for simple designs |

| Durability | Excellent; ink penetrates fabric, resists fading and cracking | Good; surface-level ink, may crack or fade over time |

| Fabric Compatibility | 100% polyester or high polyester blend required | Works on polyester and other fabrics |

| Production Volume | Ideal for small to medium runs | Cost-effective for large runs |

| Cost | Higher setup cost, lower per-unit for small batches | Lower setup cost, economical for bulk printing |

| Design Flexibility | Unlimited color range, complex gradients supported | Limited colors due to screen setup |

| Environmental Impact | Water-based inks, less waste | May use plastisol inks, more chemical waste |

Understanding Polyester as a Printing Substrate

Polyester's synthetic fibers make it highly compatible with dye sublimation, allowing dyes to penetrate the fabric for vibrant, long-lasting prints that are resistant to fading and cracking. Screen printing on polyester requires specialized inks like plastisol or water-based formulas to ensure adhesion and durability, but often results in a heavier, less breathable finish compared to dye sublimation. Understanding polyester's hydrophobic nature is crucial, as it influences ink absorption and print quality, with dye sublimation offering superior color vibrancy and durability on this substrate.

What is Dye Sublimation Printing on Polyester?

Dye sublimation printing on polyester involves infusing dye directly into the fabric fibers using heat and pressure, resulting in vibrant, durable, and colorfast prints. Unlike screen printing, which applies ink on the surface of polyester, dye sublimation produces a soft feel with no cracking or peeling over time. This method is ideal for detailed, full-color designs and performs best on polyester or polymer-coated substrates.

Screen Printing on Polyester: Process Overview

Screen printing on polyester involves pushing ink through a fine mesh stencil directly onto the fabric, allowing precise and vibrant designs that adhere well to the synthetic fibers. This method requires curing the ink with heat to ensure durability and wash resistance, making it ideal for high-quality, long-lasting prints on polyester garments. Compared to dye sublimation, screen printing offers more versatility in ink types and color opacity, especially on darker polyester fabrics.

Color Vibrancy: Dye Sublimation vs. Screen Printing

Dye sublimation on polyester produces exceptional color vibrancy by infusing the dye directly into the fabric fibers, resulting in vivid, long-lasting hues that resist fading and cracking. Screen printing on polyester offers good color opacity and brightness but tends to create a raised texture that can diminish over time with washing and wear. The sublimation process ensures seamless, vibrant designs ideal for high-performance polyester sportswear and apparel requiring rich, durable color intensity.

Durability and Washability Comparison

Dye sublimation on polyester offers superior durability and washability due to the ink chemically bonding with the fabric fibers, resulting in vibrant colors that resist fading and cracking even after multiple washes. Screen printing deposits a layer of ink on the surface, which can crack, peel, or fade over time, especially under frequent laundering or exposure to harsh detergents. Therefore, dye sublimation provides enhanced longevity and color retention on polyester garments compared to traditional screen printing methods.

Design Complexity and Detail Capabilities

Dye sublimation on polyester excels in capturing intricate design complexity with vibrant, detailed, and full-color prints that penetrate the fabric, ensuring long-lasting and fade-resistant results. Screen printing on polyester is better suited for bold, solid colors and simpler designs, as layering multiple colors can lead to less precise detail and a heavier feel on the fabric. For high-detail, photo-realistic images and complex patterns, dye sublimation remains the superior method on polyester substrates.

Production Efficiency and Turnaround Time

Dye sublimation on polyester offers superior production efficiency with faster turnaround times due to its digital, print-ready process that eliminates the need for screens and setup. Screen printing on polyester requires multiple steps, including screen preparation and curing, which extend the production timeline and reduce flexibility for small runs or custom designs. High-demand orders benefit from dye sublimation's ability to produce vibrant, durable prints rapidly, while screen printing is more suited to large batch runs but with longer lead times.

Cost Analysis: Dye Sublimation vs. Screen Printing

Dye sublimation on polyester typically incurs higher initial setup costs due to specialized printers and transfer papers but offers cost efficiency for large runs with vibrant, full-color designs. Screen printing on polyester involves lower startup expenses but becomes less economical for complex, multi-color prints and smaller batches due to ink and labor costs. Overall, dye sublimation minimizes cost per unit for detailed, high-volume applications, while screen printing remains cost-effective for simple, low-volume polyester prints.

Environmental Impact of Each Printing Method

Dye sublimation on polyester uses less water and produces minimal chemical waste compared to screen printing, making it a more environmentally friendly option. Screen printing involves the use of plastisol inks and solvents that contribute to greater water pollution and hazardous waste generation. The energy consumption in dye sublimation is typically lower due to fewer processing steps, reducing its overall carbon footprint relative to screen printing.

Choosing the Best Printing Method for Your Polyester Product

Dye sublimation on polyester offers vibrant, long-lasting colors by infusing ink directly into the fabric, ensuring excellent durability and no cracking or peeling, ideal for detailed and colorful designs. Screen printing on polyester delivers bold, opaque prints suitable for simple, solid colors but may face challenges with ink adherence and flexibility on synthetic fibers. Choosing the best printing method depends on your design complexity, color vibrancy preference, and the polyester product's end-use, with dye sublimation favored for high-detail and full-color prints while screen printing suits bulk, cost-effective runs of simpler designs.

Dye Sublimation on Polyester vs Screen Printing on Polyester Infographic

materialdif.com

materialdif.com