Cationic dyeable polyester offers vibrant, long-lasting colors compared to standard polyester, which typically requires disperse dyes that result in less vivid hues. Its modified polymer structure allows for better dye absorption and colorfastness, making it ideal for fashion and technical textiles demanding rich, durable coloration. This enhanced dyeability also supports more sustainable production by reducing the need for harsh chemicals and energy-intensive dyeing processes.

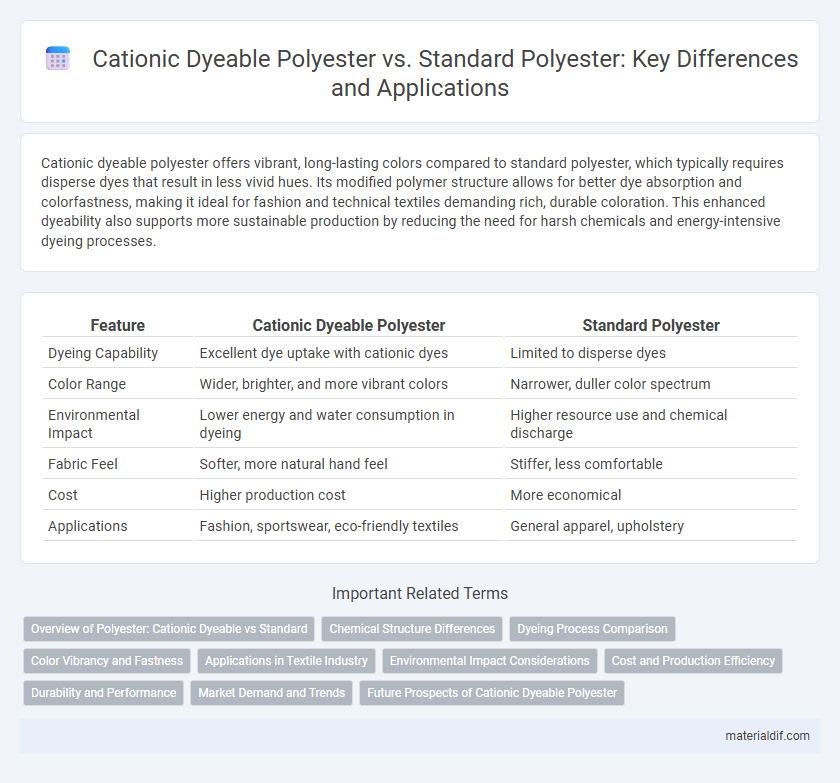

Table of Comparison

| Feature | Cationic Dyeable Polyester | Standard Polyester |

|---|---|---|

| Dyeing Capability | Excellent dye uptake with cationic dyes | Limited to disperse dyes |

| Color Range | Wider, brighter, and more vibrant colors | Narrower, duller color spectrum |

| Environmental Impact | Lower energy and water consumption in dyeing | Higher resource use and chemical discharge |

| Fabric Feel | Softer, more natural hand feel | Stiffer, less comfortable |

| Cost | Higher production cost | More economical |

| Applications | Fashion, sportswear, eco-friendly textiles | General apparel, upholstery |

Overview of Polyester: Cationic Dyeable vs Standard

Cationic dyeable polyester differs from standard polyester by its modified molecular structure, allowing superior affinity for cationic dyes that produce vibrant and diverse colors not achievable with standard disperse dyes. Standard polyester resists dye absorption due to its hydrophobic nature, requiring high-temperature and high-pressure dyeing processes, whereas cationic dyeable polyester enables more energy-efficient, low-temperature dyeing. This innovation expands design possibilities and improves colorfastness in textile applications.

Chemical Structure Differences

Cationic dyeable polyester differs from standard polyester by incorporating modified copolymers with cationic dye sites, typically through the introduction of amine groups into the polymer chain, enhancing dye affinity. This chemical structure modification allows cationic dyeable polyester to bond with basic (cationic) dyes, unlike standard polyester which primarily interacts with disperse dyes due to its hydrophobic ester backbone. The presence of these cationic sites significantly improves coloration depth and dyeing versatility compared to unmodified polyester.

Dyeing Process Comparison

Cationic dyeable polyester enables vibrant, uniform coloration at lower temperatures compared to standard polyester, which typically requires high heat and pressure for dye fixation. The dyeing process for cationic polyester uses cationic dyes that bond more effectively with the modified fiber structure, resulting in enhanced color fastness and reduced environmental impact due to lower energy consumption. Standard polyester relies on disperse dyes that necessitate higher temperatures and longer dyeing cycles, often leading to higher water and energy usage.

Color Vibrancy and Fastness

Cationic dyeable polyester exhibits significantly enhanced color vibrancy compared to standard polyester due to its unique chemical structure that allows deeper dye penetration. This material also offers superior colorfastness, maintaining brightness and resistance to fading through multiple washes and UV exposure. Standard polyester often struggles with color retention, resulting in duller hues and quicker fading over time.

Applications in Textile Industry

Cationic dyeable polyester offers superior color vibrancy and dye affinity compared to standard polyester, making it ideal for high-end fashion and performance sportswear where rich, long-lasting colors are essential. This variant enhances fabric comfort and breathability, expanding its use in activewear, upholstery, and home textiles. Standard polyester remains prevalent in industrial textiles and cost-effective garments due to its durability and abrasion resistance, but lacks the enhanced dyeability critical for vivid textile designs.

Environmental Impact Considerations

Cationic dyeable polyester significantly reduces environmental impact by enabling lower temperature dyeing and minimizing the use of hazardous chemicals compared to standard polyester. This fiber type improves water and energy efficiency, leading to less wastewater pollution and decreased carbon footprint during textile processing. The eco-friendly dyeing process of cationic dyeable polyester supports sustainable manufacturing practices in the fashion and textile industries.

Cost and Production Efficiency

Cationic dyeable polyester typically incurs higher production costs compared to standard polyester due to specialized raw materials and modified polymerization processes required for enhanced dye affinity. Despite increased initial expenses, cationic dyeable polyester offers improved dyeing efficiency with reduced water and energy consumption, which can lower operational costs over time. Standard polyester production benefits from well-established, cost-effective manufacturing methods, but often involves more intensive dyeing processes that can lead to higher resource use and longer cycle times.

Durability and Performance

Cationic dyeable polyester offers enhanced colorfastness and superior dye uptake compared to standard polyester, resulting in vibrant and long-lasting hues even after repeated washing. The molecular modification in cationic polyester enhances fiber strength and abrasion resistance, improving overall durability and performance in demanding applications. Standard polyester provides good durability but lacks the advanced dyeability and consistent color retention found in cationic dyeable variants.

Market Demand and Trends

Cationic dyeable polyester is experiencing increased market demand due to its superior dyeing properties and vibrant colorfastness compared to standard polyester, appealing to the fashion and sportswear industries seeking high-quality, sustainable fabrics. The trend towards eco-friendly and energy-efficient textile production is driving brands to prefer cationic dyeable polyester for reduced water and chemical use during dyeing processes. Market forecasts indicate a steady growth rate for cationic dyeable polyester, outpacing standard polyester as consumer preferences shift toward innovative, sustainable materials.

Future Prospects of Cationic Dyeable Polyester

Cationic dyeable polyester offers significant advantages over standard polyester by enabling vibrant, eco-friendly coloration with lower water and energy consumption. This innovation aligns with industry demands for sustainable textile production and circular fashion, positioning cationic dyeable polyester as a key material for future green manufacturing trends. Market forecasts predict a growing adoption rate driven by increasing environmental regulations and consumer preference for sustainable apparel options.

Cationic Dyeable Polyester vs Standard Polyester Infographic

materialdif.com

materialdif.com