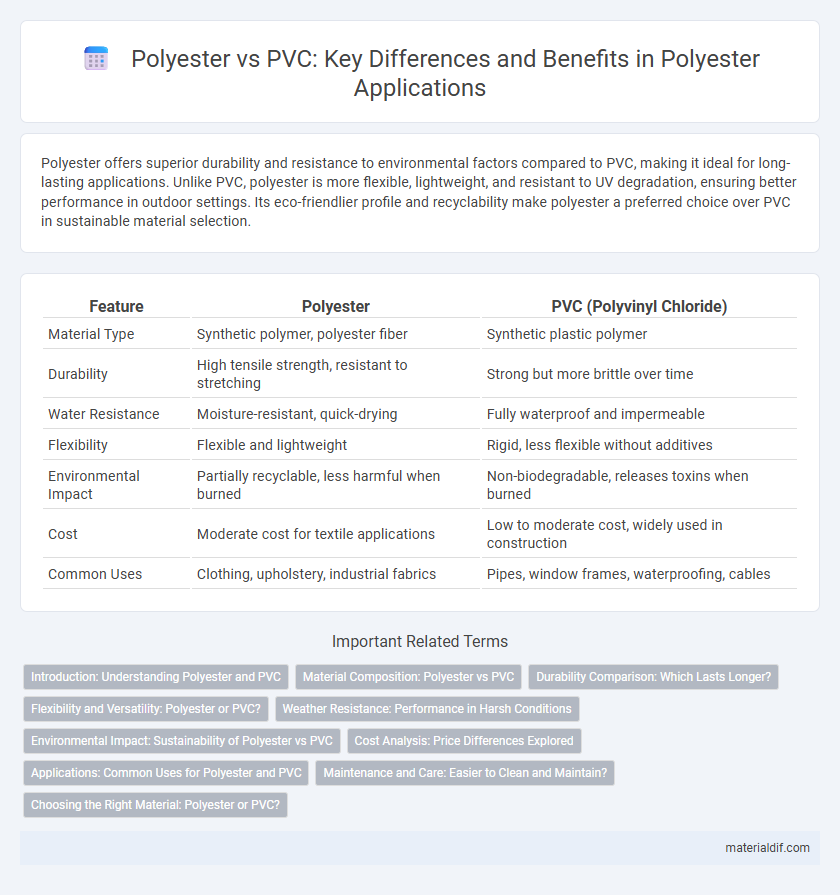

Polyester offers superior durability and resistance to environmental factors compared to PVC, making it ideal for long-lasting applications. Unlike PVC, polyester is more flexible, lightweight, and resistant to UV degradation, ensuring better performance in outdoor settings. Its eco-friendlier profile and recyclability make polyester a preferred choice over PVC in sustainable material selection.

Table of Comparison

| Feature | Polyester | PVC (Polyvinyl Chloride) |

|---|---|---|

| Material Type | Synthetic polymer, polyester fiber | Synthetic plastic polymer |

| Durability | High tensile strength, resistant to stretching | Strong but more brittle over time |

| Water Resistance | Moisture-resistant, quick-drying | Fully waterproof and impermeable |

| Flexibility | Flexible and lightweight | Rigid, less flexible without additives |

| Environmental Impact | Partially recyclable, less harmful when burned | Non-biodegradable, releases toxins when burned |

| Cost | Moderate cost for textile applications | Low to moderate cost, widely used in construction |

| Common Uses | Clothing, upholstery, industrial fabrics | Pipes, window frames, waterproofing, cables |

Introduction: Understanding Polyester and PVC

Polyester is a synthetic polymer widely used in textiles and packaging, valued for its durability, resistance to shrinking, and elasticity. PVC (polyvinyl chloride) is a versatile plastic commonly utilized in construction, electrical insulation, and pipes, noted for its rigidity and chemical resistance. Understanding the distinct chemical compositions and applications of polyester and PVC highlights their unique properties and suitability for diverse industrial uses.

Material Composition: Polyester vs PVC

Polyester is a synthetic polymer made from petroleum-derived terephthalic acid and ethylene glycol, forming a durable and flexible fabric with excellent moisture-wicking properties. PVC (polyvinyl chloride), on the other hand, is a plastic polymer composed of vinyl chloride monomers, characterized by rigidity and resistance to chemicals and water but limited breathability. The key difference lies in polyester's fabric-like textile properties versus PVC's plastic-like, waterproof nature, influencing their applications in clothing and industrial materials.

Durability Comparison: Which Lasts Longer?

Polyester exhibits superior durability compared to PVC due to its resistance to stretching, shrinking, and abrasion, making it ideal for long-term use in textiles and composites. PVC can deteriorate under prolonged exposure to UV rays and extreme temperatures, leading to cracking and brittleness over time. Polyester's robust molecular structure allows it to maintain integrity and longevity even in harsh environmental conditions.

Flexibility and Versatility: Polyester or PVC?

Polyester offers superior flexibility compared to PVC, making it ideal for applications requiring durable yet pliable materials such as textiles and flexible packaging. Its versatility spans across textiles, industrial fabrics, and films, adapting well to various environmental conditions without compromising shape or strength. PVC, while durable and resistant to chemicals, tends to be more rigid and less adaptable in applications demanding frequent bending or stretching.

Weather Resistance: Performance in Harsh Conditions

Polyester exhibits superior weather resistance compared to PVC, maintaining its structural integrity and colorfastness under prolonged exposure to UV rays, moisture, and temperature fluctuations. Unlike PVC, which tends to become brittle and crack in harsh conditions, polyester's molecular structure provides enhanced durability and flexibility, making it ideal for outdoor applications. This resilience contributes to longer service life and reduced maintenance costs in environments with extreme weather.

Environmental Impact: Sustainability of Polyester vs PVC

Polyester, derived primarily from petroleum-based products, has a lower overall environmental impact compared to PVC, which releases harmful dioxins during production and disposal. Polyester is more recyclable and generates fewer toxic byproducts, contributing to greater sustainability in textile and packaging applications. However, microplastic pollution from polyester remains a significant environmental concern, necessitating improved waste management and sustainable production methods.

Cost Analysis: Price Differences Explored

Polyester typically costs less than PVC due to its lower production expenses and raw material availability, making it a more economical choice for various applications. PVC manufacturing involves complex chemical processes and additives, which increase its overall price compared to polyester fibers or films. Cost differences also vary by product type, with polyester offering better value in textiles, while PVC remains competitive in heavy-duty industrial uses.

Applications: Common Uses for Polyester and PVC

Polyester is widely used in textiles, packaging, and industrial fabrics due to its durability, flexibility, and resistance to shrinking and stretching. PVC, or polyvinyl chloride, is commonly utilized in construction for pipes, window frames, and flooring because of its rigidity and chemical resistance. Both materials find unique applications based on their physical properties, with polyester favored in wearable and flexible products, while PVC suits structural and waterproofing needs.

Maintenance and Care: Easier to Clean and Maintain?

Polyester fabrics are generally easier to clean and maintain compared to PVC materials due to their resistance to stains and quick-drying properties. Polyester's durability allows for frequent washing without degradation, unlike PVC, which can become sticky or crack over time if not properly cared for. Regular maintenance of polyester typically involves simple machine washing or spot cleaning, whereas PVC often requires specialized cleaners to prevent damage and preserve its appearance.

Choosing the Right Material: Polyester or PVC?

Choosing between polyester and PVC depends on factors like durability, flexibility, and environmental impact. Polyester offers superior breathability and UV resistance, making it ideal for outdoor applications requiring longevity, while PVC provides excellent waterproofing and chemical resistance suited for heavy-duty uses. Consider the specific project needs, including exposure conditions and sustainability goals, to select the optimal material.

Polyester vs PVC Infographic

materialdif.com

materialdif.com