Polyester yarn consists of short staple fibers twisted together, providing softness and flexibility suited for textiles and garments, while polyester filament is made of long continuous fibers, offering higher strength and a smooth surface ideal for industrial applications and high-quality fabrics. The distinction impacts durability, texture, and performance, with yarn favored in apparel and filament preferred for technical uses. Understanding these differences guides optimal material selection for specific polyester PET products.

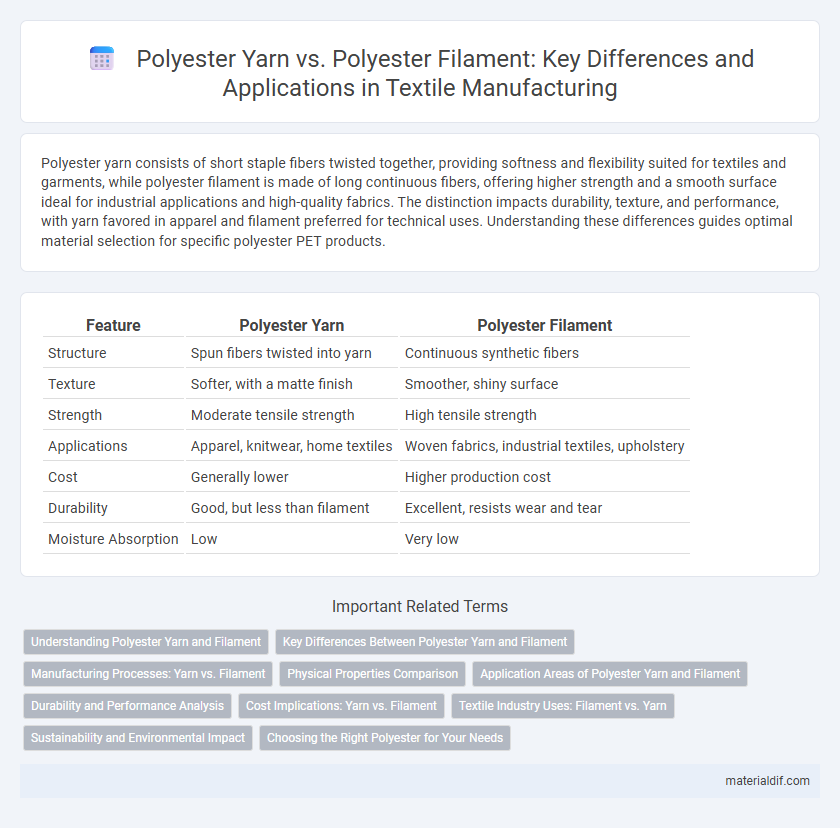

Table of Comparison

| Feature | Polyester Yarn | Polyester Filament |

|---|---|---|

| Structure | Spun fibers twisted into yarn | Continuous synthetic fibers |

| Texture | Softer, with a matte finish | Smoother, shiny surface |

| Strength | Moderate tensile strength | High tensile strength |

| Applications | Apparel, knitwear, home textiles | Woven fabrics, industrial textiles, upholstery |

| Cost | Generally lower | Higher production cost |

| Durability | Good, but less than filament | Excellent, resists wear and tear |

| Moisture Absorption | Low | Very low |

Understanding Polyester Yarn and Filament

Polyester yarn consists of short staple fibers twisted together, providing softness and flexibility suitable for woven and knitted fabrics, while polyester filament is made of continuous, long fibers offering strength, smoothness, and durability ideal for technical textiles and performance wear. The choice between yarn and filament impacts fabric texture, appearance, and end-use functionality, with yarns favoring comfort and filaments excelling in resilience and luster. Understanding these differences is crucial for textile manufacturers aiming to optimize fabric performance for applications ranging from fashion apparel to industrial uses.

Key Differences Between Polyester Yarn and Filament

Polyester yarn consists of continuous or staple fibers spun into threads, offering flexibility and softness suitable for weaving and knitting, whereas polyester filament is a continuous, smooth strand that provides higher tensile strength and durability. Yarn typically enhances fabric texture and comfort, while filament contributes to fabric sheen and resistance to wear and tear. The choice between polyester yarn and filament affects the end use, with yarn favored in apparel and filament preferred in technical textiles.

Manufacturing Processes: Yarn vs. Filament

Polyester yarn is produced by spinning staple fibers into continuous threads, involving processes such as carding, drawing, and twisting to create textured, versatile yarns suitable for various textile applications. Polyester filament manufacturing involves extruding molten polymer through spinnerets to form smooth, continuous filaments that offer strength and uniformity, ideal for high-performance fabrics. The key difference lies in polyester yarn's use of staple fiber aggregation versus filament's continuous fiber extrusion, influencing fabric texture, strength, and application.

Physical Properties Comparison

Polyester yarn typically consists of short staple fibers twisted together, resulting in a softer texture and higher flexibility compared to polyester filament, which is made from continuous, smooth strands offering superior strength and durability. The tensile strength of polyester filament is generally higher, making it ideal for industrial applications, while polyester yarn provides better breathability and comfort for textile uses. Moisture-wicking and wrinkle resistance remain consistent across both forms due to the inherent hydrophobic nature of polyester fibers.

Application Areas of Polyester Yarn and Filament

Polyester yarn is widely used in textile manufacturing for apparel, home furnishings, and industrial fabrics due to its softness, flexibility, and ease of dyeing. Polyester filament finds extensive application in high-strength industrial uses, including tire cords, conveyor belts, and geotextiles, where durability and resistance to abrasion are critical. Both forms serve distinct markets, with yarn preferred in fashion and upholstery, and filament dominant in technical textiles and heavy-duty industrial products.

Durability and Performance Analysis

Polyester yarn exhibits excellent durability due to its high tensile strength and resistance to abrasion, making it ideal for heavy-duty textile applications. Polyester filament fibers offer superior performance in terms of smoothness, uniformity, and moisture-wicking properties, enhancing fabric appearance and comfort. Comparative analysis reveals polyester filament's advantage in high-performance activewear, while polyester yarn remains preferred for upholstery and industrial textiles requiring robust resilience.

Cost Implications: Yarn vs. Filament

Polyester yarn generally incurs higher production costs than polyester filament due to the additional spinning and twisting processes required. Polyester filament, produced as continuous strands, benefits from streamlined manufacturing and lower raw material wastage, resulting in cost-efficiency. The choice between yarn and filament significantly impacts the overall textile production budget and material pricing in the polyester market.

Textile Industry Uses: Filament vs. Yarn

Polyester yarn consists of short staple fibers spun together, making it ideal for knitting and weaving soft, breathable fabrics used in apparel and home textiles. Polyester filament is produced as continuous strands, offering high strength and smoothness, favored in technical textiles, industrial applications, and high-performance sportswear. The textile industry leverages yarn for flexibility and texture, while filament is chosen for durability and luster in fabrics.

Sustainability and Environmental Impact

Polyester yarn and polyester filament differ significantly in sustainability and environmental impact due to their production processes. Polyester yarn, often spun from recycled PET bottles, promotes circular economy practices by reducing plastic waste and energy consumption compared to virgin polyester filament, which is produced through petrochemical processes with higher carbon emissions and reliance on non-renewable resources. Choosing recycled polyester yarn over filament enhances resource efficiency and minimizes ecological footprint in textile manufacturing.

Choosing the Right Polyester for Your Needs

Polyester yarn offers enhanced flexibility and breathability ideal for apparel and knitwear, while polyester filament provides superior strength and durability suited for industrial textiles and upholstery. Selecting the right polyester depends on the end-use requirements such as tensile strength, texture, and fabric weight. Consider polyester filament for high-performance applications requiring resilience, and polyester yarn for comfort-driven products emphasizing softness and stretch.

Polyester yarn vs Polyester filament Infographic

materialdif.com

materialdif.com