Polyester film offers a thin, flexible layer ideal for packaging, insulation, and graphics applications, delivering excellent clarity and tensile strength. Polyester sheets are thicker and more rigid, suited for structural uses such as automotive parts, signage, and electronic components requiring durability and impact resistance. Choosing between polyester film and sheet depends on the specific requirements for flexibility, thickness, and mechanical strength in your project.

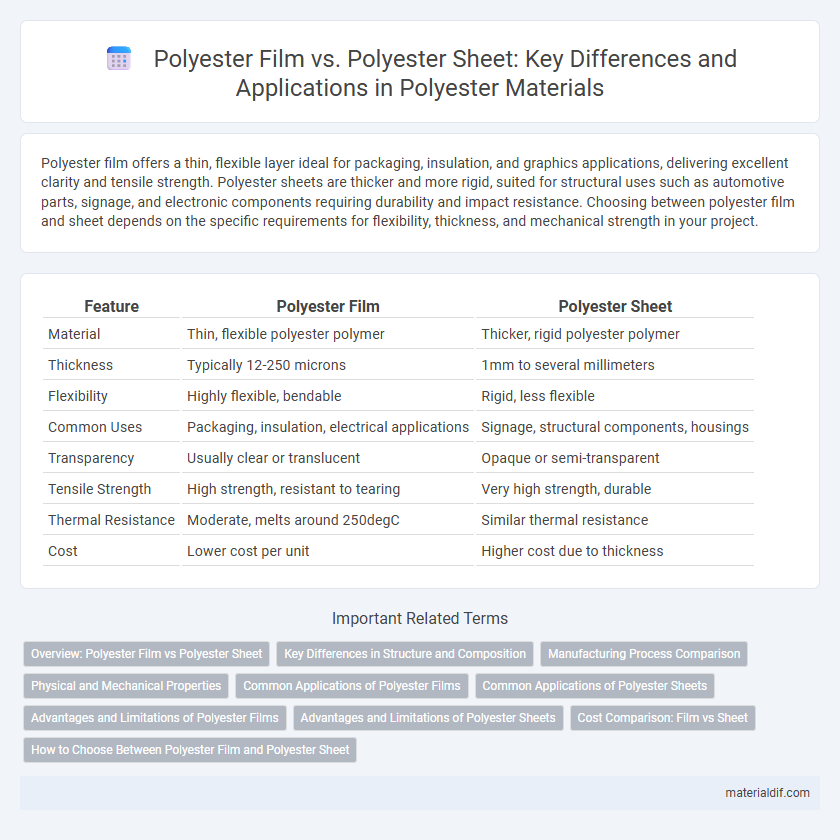

Table of Comparison

| Feature | Polyester Film | Polyester Sheet |

|---|---|---|

| Material | Thin, flexible polyester polymer | Thicker, rigid polyester polymer |

| Thickness | Typically 12-250 microns | 1mm to several millimeters |

| Flexibility | Highly flexible, bendable | Rigid, less flexible |

| Common Uses | Packaging, insulation, electrical applications | Signage, structural components, housings |

| Transparency | Usually clear or translucent | Opaque or semi-transparent |

| Tensile Strength | High strength, resistant to tearing | Very high strength, durable |

| Thermal Resistance | Moderate, melts around 250degC | Similar thermal resistance |

| Cost | Lower cost per unit | Higher cost due to thickness |

Overview: Polyester Film vs Polyester Sheet

Polyester film and polyester sheet both consist of polyethylene terephthalate (PET) but differ in form and application; polyester film is a thin, flexible material commonly used for packaging, insulation, and photographic films, while polyester sheet is thicker and rigid, ideal for structural applications and fabrication. Polyester film offers high tensile strength, chemical resistance, and excellent dimensional stability, making it suitable for electronic and optical uses, whereas polyester sheet provides superior impact resistance and durability in mechanical and industrial settings. Selection between polyester film and sheet depends on the specific physical properties required and intended application environment.

Key Differences in Structure and Composition

Polyester film is a thin, flexible material typically produced through biaxial orientation, giving it enhanced tensile strength and dimensional stability, whereas polyester sheet is thicker, less flexible, and often manufactured by casting or extrusion processes. The molecular structure of polyester film includes tightly packed polymer chains aligned during stretching, resulting in superior clarity and barrier properties compared to the relatively amorphous structure of polyester sheets. These structural differences influence their applications, with polyester films popular in electrical insulation and packaging, while polyester sheets are favored for rigid components and protective surfaces.

Manufacturing Process Comparison

Polyester film is produced through a continuous extrusion and biaxial orientation process, which involves melting polyethylene terephthalate (PET) pellets and stretching the molten material in both machine and transverse directions to enhance strength and clarity. In contrast, polyester sheets are typically manufactured via casting or calendaring, where molten polymer is directly formed into thicker, flat sheets without the orientation step, resulting in different mechanical properties. The biaxial orientation in polyester film manufacturing leads to superior tensile strength and dimensional stability compared to the more rigid and less flexible polyester sheets.

Physical and Mechanical Properties

Polyester film exhibits superior flexibility, tensile strength up to 200 MPa, and excellent dimensional stability, making it ideal for applications requiring thin, durable layers. Polyester sheet provides enhanced rigidity with thickness typically ranging from 0.5 mm to 3 mm, offering higher impact resistance and better load-bearing capacity. Both materials maintain high chemical resistance and thermal stability, with polyester sheet preferred for structural uses and polyester film favored in insulation and packaging.

Common Applications of Polyester Films

Polyester films are widely used in electrical insulation, packaging, and photographic applications due to their excellent tensile strength, chemical resistance, and dimensional stability. Common applications include capacitor wraps, flexible printed circuit boards, and food packaging films because of their clarity and barrier properties. In contrast, polyester sheets serve primarily in structural and decorative uses, offering rigidity and impact resistance where film flexibility is not required.

Common Applications of Polyester Sheets

Polyester sheets are widely used in electrical insulation due to their excellent dielectric strength and durability, making them ideal for motor, transformer, and capacitor components. Their chemical resistance and dimensional stability allow applications in gaskets, seals, and flexible printed circuit boards. Unlike polyester film, sheets provide greater thickness and rigidity, suitable for structural parts and protective covers in automotive and industrial equipment.

Advantages and Limitations of Polyester Films

Polyester films offer superior flexibility, excellent dimensional stability, and high tensile strength compared to polyester sheets, making them ideal for packaging, insulation, and graphic applications. Their transparency and resistance to moisture, chemicals, and UV radiation enhance durability and suitability for optical and electrical uses. However, polyester films tend to be less rigid and thicker than sheets, limiting their structural support capabilities in certain industrial applications.

Advantages and Limitations of Polyester Sheets

Polyester sheets offer enhanced mechanical strength and superior chemical resistance compared to polyester film, making them ideal for applications requiring durability and structural integrity. They provide excellent dimensional stability and thermal resistance but tend to be thicker and less flexible, which limits their use in applications demanding high conformability. The rigidity of polyester sheets can be a disadvantage in processes where bending or folding is necessary, while their superior surface finish and toughness make them suitable for protective panels and industrial components.

Cost Comparison: Film vs Sheet

Polyester film typically offers a lower cost per unit area compared to polyester sheet due to its thinner gauge and efficient production process. Polyester sheets, being thicker and more rigid, generally involve higher raw material consumption and manufacturing expenses, resulting in increased price points. Budget-conscious industries often prefer polyester film when flexibility and cost-effectiveness are crucial, while polyester sheets are chosen for applications requiring durability despite higher costs.

How to Choose Between Polyester Film and Polyester Sheet

Choosing between polyester film and polyester sheet depends primarily on the intended application's flexibility and thickness requirements. Polyester film offers a thin, flexible solution ideal for electrical insulation, packaging, and graphic arts, while polyester sheet provides a thicker, more rigid option suitable for structural components, signage, and protective barriers. Consider the mechanical strength, transparency, and surface finish needed to match the specific performance criteria of your project.

Polyester Film vs Polyester Sheet Infographic

materialdif.com

materialdif.com