Cationic dyeable polyester offers superior color vibrancy and dye absorption compared to regular polyester, enabling richer and more diverse color options. This type of polyester incorporates special cationic sites that allow compatibility with disperse and cationic dyes, resulting in enhanced colorfastness and reduced dye bleeding. Regular polyester typically resists dye penetration, which limits its color intensity and flexibility in textile applications.

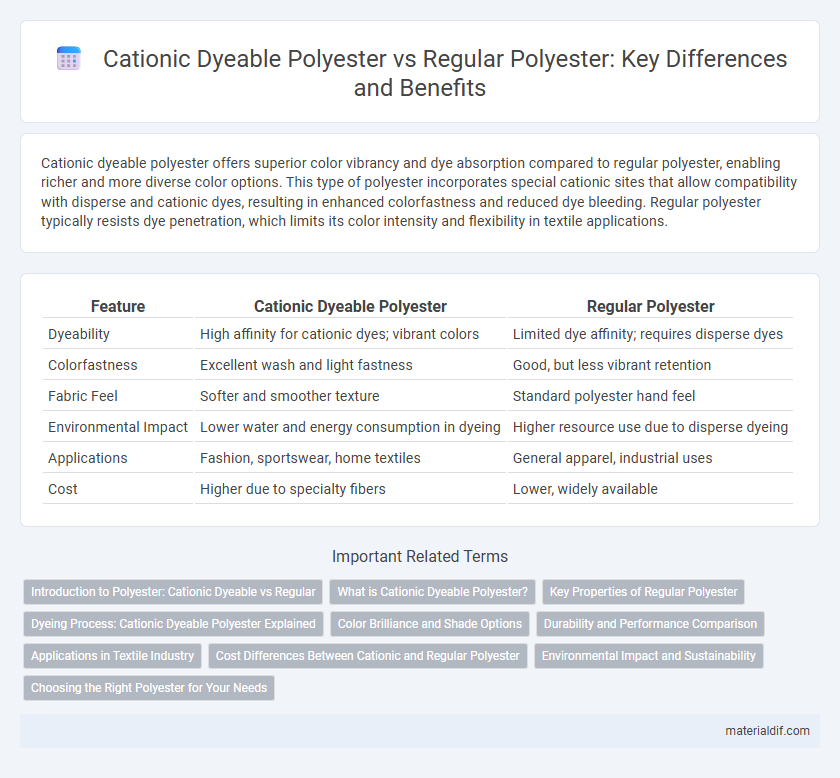

Table of Comparison

| Feature | Cationic Dyeable Polyester | Regular Polyester |

|---|---|---|

| Dyeability | High affinity for cationic dyes; vibrant colors | Limited dye affinity; requires disperse dyes |

| Colorfastness | Excellent wash and light fastness | Good, but less vibrant retention |

| Fabric Feel | Softer and smoother texture | Standard polyester hand feel |

| Environmental Impact | Lower water and energy consumption in dyeing | Higher resource use due to disperse dyeing |

| Applications | Fashion, sportswear, home textiles | General apparel, industrial uses |

| Cost | Higher due to specialty fibers | Lower, widely available |

Introduction to Polyester: Cationic Dyeable vs Regular

Cationic dyeable polyester is engineered to absorb cationic dyes, enabling vibrant and diverse color options compared to regular polyester, which primarily accepts disperse dyes. The molecular structure of cationic dyeable polyester includes cationic sites that enhance dye affinity, resulting in improved colorfastness and brightness. Regular polyester lacks these modifications, leading to limited dyeability and a narrower color palette.

What is Cationic Dyeable Polyester?

Cationic dyeable polyester is a specialized type of polyester fiber chemically modified to attract and bond with cationic (basic) dyes, enabling vibrant and diverse color options that regular polyester cannot achieve due to its hydrophobic nature. Unlike regular polyester, which primarily accommodates disperse dyes, cationic dyeable polyester's modified molecular structure enhances dye uptake, resulting in brighter colors, better color fastness, and improved print clarity. This innovation elevates polyester's application in high-quality textile manufacturing, allowing for eco-friendly dyeing processes with reduced chemical usage and water consumption.

Key Properties of Regular Polyester

Regular polyester is a synthetic fiber known for its high strength, durability, and resistance to stretching and shrinking. It offers excellent moisture-wicking properties and quick-drying capabilities, making it suitable for activewear and outdoor fabrics. Its low absorbency results in limited dye uptake, leading to less vibrant colors compared to cationic dyeable polyester.

Dyeing Process: Cationic Dyeable Polyester Explained

Cationic dyeable polyester features modified molecular structures that enhance its affinity for cationic dyes, enabling vibrant and uniform coloration through an improved dyeing process compared to regular polyester. This specialized polyester absorbs cationic dyes effectively at lower temperatures and shorter times, resulting in energy-efficient and eco-friendly dyeing. The enhanced dye-fiber interaction reduces the need for carriers or auxiliary chemicals, ensuring superior colorfastness and a broader color range than conventional polyester fabrics.

Color Brilliance and Shade Options

Cationic dyeable polyester offers superior color brilliance compared to regular polyester, achieving more vibrant and intense hues due to its enhanced affinity for cationic dyes. This fiber modification enables a wider range of shade options, including bright and pastel tones that are difficult to achieve with standard polyester. As a result, textiles made from cationic dyeable polyester exhibit richer, more consistent colors with improved wash and light fastness.

Durability and Performance Comparison

Cationic dyeable polyester exhibits superior colorfastness and enhanced resistance to washing and abrasion compared to regular polyester, resulting in longer-lasting vibrant hues and maintained fabric integrity. Its modified polymer structure allows for better dye absorption without compromising tensile strength, ensuring improved durability in demanding applications. Regular polyester, while durable, tends to fade more quickly and shows less resistance to mechanical wear, making cationic dyeable polyester a preferred choice for high-performance textiles.

Applications in Textile Industry

Cationic dyeable polyester offers enhanced color vibrancy and a wider range of hues compared to regular polyester, making it ideal for high-fashion and performance apparel in the textile industry. Its improved dye affinity reduces water and energy consumption during the dyeing process, supporting sustainable manufacturing practices. Regular polyester remains preferred for cost-effective production of durable textiles such as upholstery and industrial fabrics.

Cost Differences Between Cationic and Regular Polyester

Cationic dyeable polyester generally incurs higher production costs compared to regular polyester due to the incorporation of specialized cationic sites that enhance dye affinity. This increased manufacturing expense is reflected in the final product price, making cationic polyester more expensive than standard polyester fibers. Despite the cost premium, the superior dyeability offers better colorfastness and a broader range of vibrant color options, which justifies the higher investment for specific textile applications.

Environmental Impact and Sustainability

Cationic dyeable polyester requires less water and energy during the dyeing process compared to regular polyester, significantly reducing its environmental footprint. The enhanced dye affinity of cationic dyeable polyester decreases the need for harmful chemical auxiliaries, lowering toxic effluent discharge into water systems. This sustainable approach supports reduced greenhouse gas emissions and promotes eco-friendly textile manufacturing practices.

Choosing the Right Polyester for Your Needs

Cationic dyeable polyester offers enhanced color vibrancy and a broader color range compared to regular polyester, making it ideal for applications requiring bright, intensive hues. Its modified chemical structure allows better dye uptake, resulting in excellent colorfastness and durability for fashion and performance textiles. Regular polyester remains a cost-effective option with strong mechanical properties, suitable for general uses where intense coloration is not a priority.

Cationic Dyeable Polyester vs Regular Polyester Infographic

materialdif.com

materialdif.com