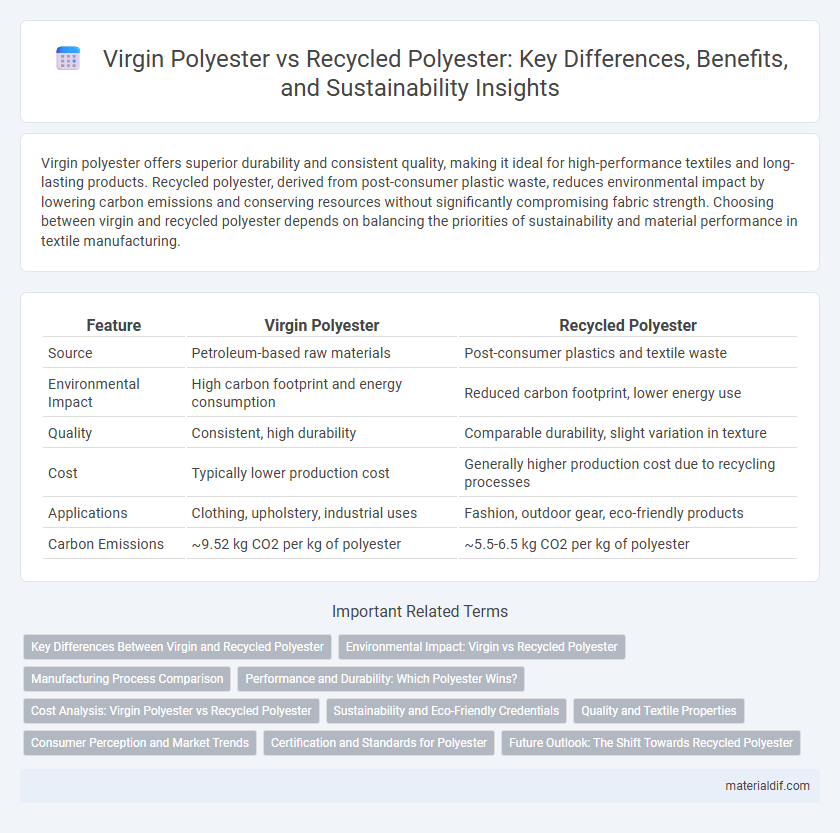

Virgin polyester offers superior durability and consistent quality, making it ideal for high-performance textiles and long-lasting products. Recycled polyester, derived from post-consumer plastic waste, reduces environmental impact by lowering carbon emissions and conserving resources without significantly compromising fabric strength. Choosing between virgin and recycled polyester depends on balancing the priorities of sustainability and material performance in textile manufacturing.

Table of Comparison

| Feature | Virgin Polyester | Recycled Polyester |

|---|---|---|

| Source | Petroleum-based raw materials | Post-consumer plastics and textile waste |

| Environmental Impact | High carbon footprint and energy consumption | Reduced carbon footprint, lower energy use |

| Quality | Consistent, high durability | Comparable durability, slight variation in texture |

| Cost | Typically lower production cost | Generally higher production cost due to recycling processes |

| Applications | Clothing, upholstery, industrial uses | Fashion, outdoor gear, eco-friendly products |

| Carbon Emissions | ~9.52 kg CO2 per kg of polyester | ~5.5-6.5 kg CO2 per kg of polyester |

Key Differences Between Virgin and Recycled Polyester

Virgin polyester is produced from petroleum-based raw materials, resulting in high purity fibers with consistent quality and strength, while recycled polyester is made from post-consumer plastic waste such as PET bottles, reducing environmental impact by diverting waste from landfills. Recycled polyester generally requires less energy and water during production, significantly lowering carbon emissions compared to virgin polyester manufacturing processes. Despite slight variations in fiber properties, advancements in recycling technology have enhanced durability and softness, making recycled polyester increasingly comparable to virgin polyester in textile applications.

Environmental Impact: Virgin vs Recycled Polyester

Virgin polyester production relies heavily on petroleum, resulting in significant carbon emissions and high energy consumption. Recycled polyester drastically reduces waste by repurposing plastic bottles and textile scraps, lowering greenhouse gas emissions by up to 75% compared to virgin fibers. The shift to recycled polyester minimizes landfill waste and conserves natural resources, making it a more sustainable choice for environmentally conscious manufacturing.

Manufacturing Process Comparison

Virgin polyester is produced from petrochemical raw materials through polymerization, involving energy-intensive processes such as cracking and refining of crude oil, resulting in high carbon emissions. Recycled polyester, often derived from post-consumer plastic bottles or textile waste, undergoes mechanical shredding and melting or chemical depolymerization, significantly reducing energy consumption and raw material extraction. The manufacturing process of recycled polyester contributes to lower environmental impact by minimizing landfill waste and reducing dependency on fossil fuels.

Performance and Durability: Which Polyester Wins?

Virgin polyester offers superior performance and durability due to its pure polymer structure, resulting in higher tensile strength, better resilience, and longer lifespan compared to recycled polyester. Recycled polyester, while more sustainable, often contains impurities or shortened polymer chains that can slightly reduce fabric strength and longevity. For high-performance textile applications requiring maximum durability, virgin polyester remains the preferred choice, though advancements in recycling technology are steadily narrowing the performance gap.

Cost Analysis: Virgin Polyester vs Recycled Polyester

Virgin polyester typically incurs higher production costs due to raw petroleum-based materials and energy-intensive manufacturing processes, leading to increased pricing in global markets. Recycled polyester, derived from post-consumer plastic waste, offers cost advantages by reducing raw material expenses and lowering environmental impact fees, making it economically attractive for sustainable textile production. Market analysis shows recycled polyester demand growth is driving economies of scale, further narrowing the cost gap with virgin polyester.

Sustainability and Eco-Friendly Credentials

Virgin polyester, derived from petroleum-based raw materials, has a higher carbon footprint and environmental impact due to energy-intensive production processes and non-renewable resource use. Recycled polyester, often made from post-consumer PET bottles, significantly reduces greenhouse gas emissions, conserves resources, and minimizes landfill waste, enhancing its sustainability profile. Brands prioritizing eco-friendly credentials increasingly incorporate recycled polyester to meet growing consumer demand for environmentally responsible textiles.

Quality and Textile Properties

Virgin polyester offers superior tensile strength, consistent fiber uniformity, and higher color retention compared to recycled polyester, making it ideal for high-performance textiles. Recycled polyester, while slightly lower in fiber durability and quality, effectively reduces environmental impact through resource conservation and lower energy consumption. Advances in recycling technology are gradually narrowing the gap in moisture wicking and abrasion resistance, enhancing the functionality of recycled polyester fabrics.

Consumer Perception and Market Trends

Virgin polyester is often perceived as having higher quality and durability, which appeals to consumers seeking long-lasting apparel, while recycled polyester gains favor due to growing environmental awareness and sustainability concerns. Market trends indicate a rising demand for recycled polyester, driven by eco-conscious brands and regulations promoting circular economies in the textile industry. This shift impacts production volumes, with recycled polyester expected to capture an increasing share of the polyester fiber market by 2030.

Certification and Standards for Polyester

Virgin polyester typically adheres to stringent industry certifications such as Oeko-Tex Standard 100 and Global Recycled Standard (GRS) to ensure purity and quality, while recycled polyester prioritizes certifications like Global Recycled Standard (GRS) and Recycled Claim Standard (RCS) to verify the traceability and sustainability of recycled content. Both types often comply with ISO 14001 environmental management standards, emphasizing responsible production and reduced environmental impact. Certification transparency plays a critical role in consumer trust, validating the polyester's origin, environmental compliance, and adherence to social responsibility practices.

Future Outlook: The Shift Towards Recycled Polyester

The future outlook of polyester production strongly favors recycled polyester due to increasing environmental regulations and rising consumer demand for sustainable products. Innovations in recycling technologies are enhancing the quality and cost-effectiveness of recycled polyester, making it a competitive alternative to virgin polyester. Industry forecasts predict a significant rise in recycled polyester market share, driven by corporate commitments to circular economy practices and carbon footprint reduction goals.

Virgin polyester vs Recycled polyester Infographic

materialdif.com

materialdif.com