Microfiber polyester features ultra-fine fibers that create a softer, more breathable fabric compared to regular polyester, enhancing comfort and moisture-wicking capabilities. Its tighter weave provides superior durability and resistance to wrinkles, making it ideal for high-performance clothing and home textiles. Regular polyester, while durable and versatile, tends to be less breathable and can feel rougher against the skin, limiting its use in applications requiring lightweight, soft materials.

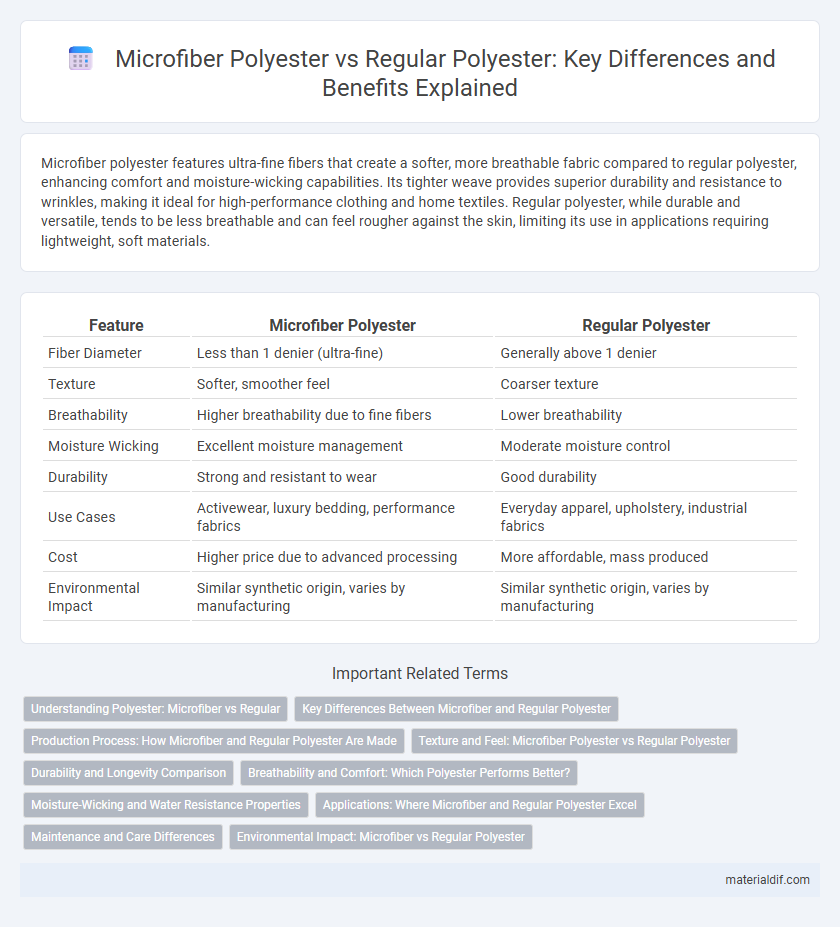

Table of Comparison

| Feature | Microfiber Polyester | Regular Polyester |

|---|---|---|

| Fiber Diameter | Less than 1 denier (ultra-fine) | Generally above 1 denier |

| Texture | Softer, smoother feel | Coarser texture |

| Breathability | Higher breathability due to fine fibers | Lower breathability |

| Moisture Wicking | Excellent moisture management | Moderate moisture control |

| Durability | Strong and resistant to wear | Good durability |

| Use Cases | Activewear, luxury bedding, performance fabrics | Everyday apparel, upholstery, industrial fabrics |

| Cost | Higher price due to advanced processing | More affordable, mass produced |

| Environmental Impact | Similar synthetic origin, varies by manufacturing | Similar synthetic origin, varies by manufacturing |

Understanding Polyester: Microfiber vs Regular

Microfiber polyester consists of extremely fine fibers, often less than one denier in diameter, resulting in a softer texture and increased breathability compared to regular polyester, which uses thicker fibers. This finer fiber structure enhances moisture-wicking properties and durability, making microfiber polyester ideal for performance and activewear fabrics. Regular polyester, while more affordable and easier to produce, tends to be less flexible and less efficient at moisture management, often used in basic apparel and home textiles.

Key Differences Between Microfiber and Regular Polyester

Microfiber polyester features ultra-fine fibers that are significantly thinner than those used in regular polyester, resulting in a softer texture and enhanced breathability. This fabric offers superior moisture-wicking and quick-drying properties compared to regular polyester, making it ideal for activewear and performance garments. Regular polyester is more durable and generally less expensive, but microfiber polyester excels in comfort and lightweight feel due to its finer fiber construction.

Production Process: How Microfiber and Regular Polyester Are Made

Microfiber polyester is produced using ultra-fine fibers measured in denier counts below 1.0, created by extruding extremely thin filaments with specialized spinneret technology, resulting in a softer and more breathable fabric. Regular polyester is manufactured from thicker fibers, typically ranging from 1.5 to 15 denier, through conventional melt-spinning processes that extrude molten polymer into continuous filaments. The finer fiber diameter in microfiber polyester requires more precise control during production, enhancing fabric density and durability compared to standard polyester.

Texture and Feel: Microfiber Polyester vs Regular Polyester

Microfiber polyester has a finer thread diameter, resulting in a softer, smoother texture compared to regular polyester, which uses thicker fibers and tends to feel coarser. The densely woven microfibers create a silky, lightweight fabric that feels more luxurious and breathable. Regular polyester, while durable and moisture-resistant, often lacks the plushness and gentle hand-feel characteristic of microfiber variations.

Durability and Longevity Comparison

Microfiber polyester exhibits superior durability compared to regular polyester due to its ultra-fine fibers, which enhance resistance to wear and tear, stretching, and fading. The dense weave structure of microfiber helps maintain fabric integrity over extended use, resulting in longer-lasting performance. Regular polyester, while durable, tends to show signs of abrasion and reduced tensile strength more quickly under frequent washing and heavy use.

Breathability and Comfort: Which Polyester Performs Better?

Microfiber polyester offers superior breathability compared to regular polyester due to its finer fibers that allow better air circulation and moisture wicking. This enhanced breathability significantly increases comfort, making microfiber polyester ideal for activewear and warm climates. Regular polyester, with its thicker fibers, tends to trap heat and moisture, often leading to less comfort during extended wear.

Moisture-Wicking and Water Resistance Properties

Microfiber polyester features finer fibers than regular polyester, enhancing its moisture-wicking capabilities by quickly drawing sweat away from the skin and promoting faster evaporation. This fabric's tightly woven structure also improves water resistance, making it more effective at repelling light rain and moisture compared to regular polyester. These properties make microfiber polyester ideal for activewear and outdoor clothing where dryness and comfort are crucial.

Applications: Where Microfiber and Regular Polyester Excel

Microfiber polyester excels in activewear, sportswear, and high-performance outdoor gear due to its superior moisture-wicking, breathability, and lightweight properties. Regular polyester is widely used in upholstery, home furnishings, and industrial fabrics because of its durability, cost-effectiveness, and resistance to wrinkles and shrinking. Both materials find applications in fashion, but microfiber polyester is preferred for luxury and technical garments while regular polyester suits everyday apparel and textile manufacturing.

Maintenance and Care Differences

Microfiber polyester requires more delicate maintenance due to its finer fibers, often necessitating lower wash temperatures and gentle detergents to prevent damage and maintain softness. Regular polyester is more resilient, tolerating higher wash temperatures and standard detergents without significant wear or loss of quality. Both types benefit from air drying over high-heat drying methods to preserve fabric integrity and extend garment lifespan.

Environmental Impact: Microfiber vs Regular Polyester

Microfiber polyester releases significantly more microplastic particles during washing, contributing to ocean pollution and harming aquatic ecosystems, whereas regular polyester sheds fewer microfibers but is less durable. Both materials rely on non-renewable fossil fuels for production, generating greenhouse gas emissions, but microfiber polyester's finer fibers lead to higher environmental contamination. Recycling efforts are more challenging for microfiber polyester due to its complex structure, resulting in increased landfill waste compared to regular polyester.

Microfiber Polyester vs Regular Polyester Infographic

materialdif.com

materialdif.com