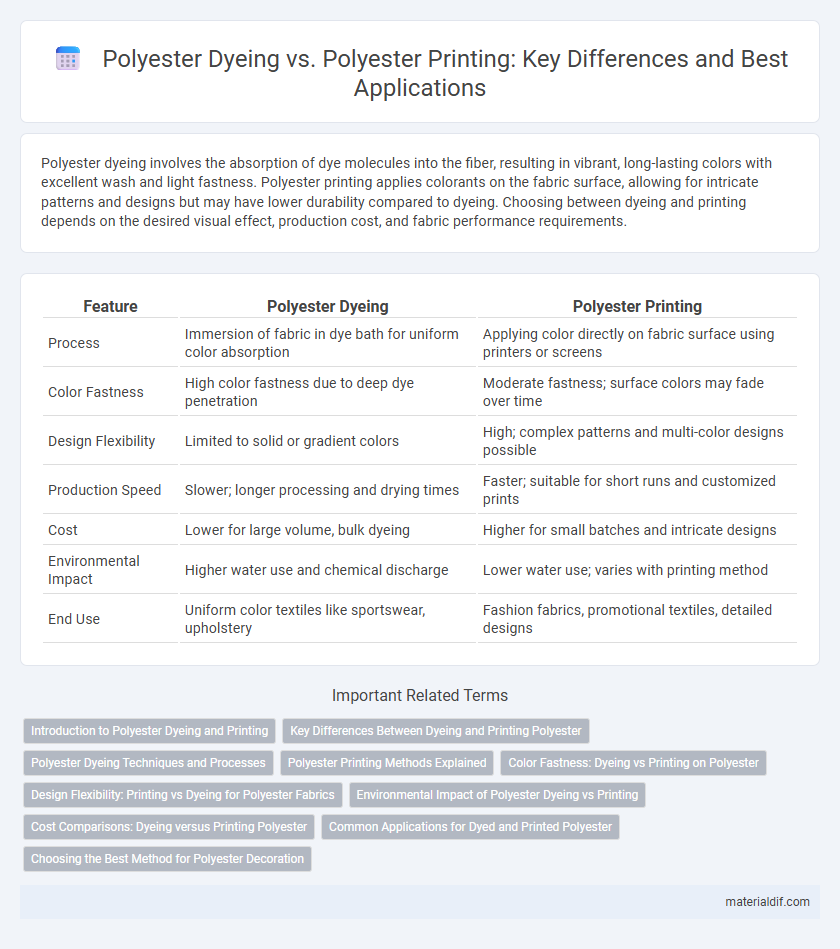

Polyester dyeing involves the absorption of dye molecules into the fiber, resulting in vibrant, long-lasting colors with excellent wash and light fastness. Polyester printing applies colorants on the fabric surface, allowing for intricate patterns and designs but may have lower durability compared to dyeing. Choosing between dyeing and printing depends on the desired visual effect, production cost, and fabric performance requirements.

Table of Comparison

| Feature | Polyester Dyeing | Polyester Printing |

|---|---|---|

| Process | Immersion of fabric in dye bath for uniform color absorption | Applying color directly on fabric surface using printers or screens |

| Color Fastness | High color fastness due to deep dye penetration | Moderate fastness; surface colors may fade over time |

| Design Flexibility | Limited to solid or gradient colors | High; complex patterns and multi-color designs possible |

| Production Speed | Slower; longer processing and drying times | Faster; suitable for short runs and customized prints |

| Cost | Lower for large volume, bulk dyeing | Higher for small batches and intricate designs |

| Environmental Impact | Higher water use and chemical discharge | Lower water use; varies with printing method |

| End Use | Uniform color textiles like sportswear, upholstery | Fashion fabrics, promotional textiles, detailed designs |

Introduction to Polyester Dyeing and Printing

Polyester dyeing involves the process of applying color to the entire fiber using disperse dyes, which penetrate the synthetic polymer to produce uniform and long-lasting hues. Polyester printing, by contrast, applies color selectively on the fabric surface using methods like sublimation printing or screen printing, allowing intricate designs with vivid patterns. Both techniques require high-temperature conditions due to polyester's hydrophobic nature, but dyeing ensures consistent coloration, whereas printing offers versatile design customization.

Key Differences Between Dyeing and Printing Polyester

Polyester dyeing involves immersing the fabric in a dye solution to achieve uniform color penetration, resulting in a consistent and long-lasting hue, while polyester printing applies color on the fabric surface creating detailed patterns or designs with localized coloration. Dyeing usually requires high temperature and pressure to bond the dye with the polyester fibers, whereas printing techniques like screen printing or digital printing deposit pigments or dyes selectively without full fiber saturation. The key difference lies in dyeing's uniform color saturation throughout the fabric compared to printing's precise, surface-level application of colors or patterns.

Polyester Dyeing Techniques and Processes

Polyester dyeing techniques primarily involve disperse dyeing methods such as high-temperature pressure dyeing, carrier dyeing, and supercritical CO2 dyeing to ensure deep penetration and vibrant colors. These processes rely on the hydrophobic nature of polyester fibers, using disperse dyes that sublimate under heat, allowing uniform coloration and excellent wash fastness. Compared to printing, dyeing achieves thorough color integration into the fiber, enhancing durability and color consistency for industrial and textile applications.

Polyester Printing Methods Explained

Polyester printing methods encompass techniques like sublimation, screen printing, and digital printing, each offering unique advantages for vibrant, durable designs. Sublimation printing involves transferring dye onto polyester fabric using heat, resulting in high-quality, permanent colors that resist fading and cracking. Screen printing applies layers of ink through a mesh stencil, ideal for bold patterns, while digital printing allows for intricate, multi-colored designs with short production runs and minimal waste.

Color Fastness: Dyeing vs Printing on Polyester

Polyester dyeing involves penetrating the fiber with disperse dyes, resulting in superior color fastness to washing, light, and rubbing compared to printing methods. Polyester printing, often using pigment or disperse inks applied on the fabric surface, tends to show lower durability and color retention under frequent laundering and exposure to sunlight. Enhanced heat-setting techniques during dyeing further improve the fixation of color molecules within polyester fibers, ensuring long-lasting vibrancy and resistance to fading.

Design Flexibility: Printing vs Dyeing for Polyester Fabrics

Printing on polyester fabrics offers superior design flexibility compared to dyeing, allowing intricate patterns, multiple colors, and precise details to be applied directly to the fabric surface. Dyeing penetrates the fibers, resulting in solid, uniform colors but with limited pattern complexity and color variation. This makes printing the preferred method for vibrant, detailed, and customized designs on polyester textiles.

Environmental Impact of Polyester Dyeing vs Printing

Polyester dyeing typically consumes more water and energy compared to polyester printing, leading to a higher environmental footprint due to the intensive use of chemicals and wastewater generation. Printing on polyester fabric often uses less water and produces less pollution, especially when digital printing techniques are employed, making it a more eco-friendly option. Sustainable practices in both dyeing and printing, such as low-impact dyes and waterless printing technologies, are critical to reducing the environmental impact of polyester textile production.

Cost Comparisons: Dyeing versus Printing Polyester

Polyester dyeing generally incurs higher initial costs due to the need for specialized machinery and longer processing times, while printing on polyester fabrics tends to be more cost-effective for small batches and designs with multiple colors. Printing processes such as sublimation or digital printing use less water and energy, lowering operational expenses compared to traditional dyeing methods like disperse dyeing. For large-scale production, dyeing may offer better economies of scale, but printing provides greater flexibility and faster turnaround times at a comparatively lower cost for custom or low-volume orders.

Common Applications for Dyed and Printed Polyester

Dyed polyester is commonly used in activewear, outdoor gear, and upholstery where consistent color saturation and durability are essential. Printed polyester finds frequent application in fashion apparel, promotional textiles, and home decor, offering versatility with complex patterns and vibrant designs. Both techniques enhance polyester's performance characteristics, catering to diverse industrial and consumer needs.

Choosing the Best Method for Polyester Decoration

Polyester dyeing penetrates fibers, offering vibrant, long-lasting color ideal for all-over designs and superior wash durability. Polyester printing applies pigment on the surface, allowing intricate patterns and multi-color artwork but may lack the same depth and longevity as dyeing. Selecting between dyeing and printing depends on the desired design complexity, colorfastness, and fabric texture requirements for polyester decoration.

Polyester Dyeing vs Polyester Printing Infographic

materialdif.com

materialdif.com