Textured polyester features a crimped or twisted fiber structure that enhances its durability, elasticity, and moisture-wicking properties, making it ideal for activewear and outdoor textiles. Flat polyester, with its smooth and uniform surface, offers a sleek appearance and is commonly used in linings, lightweight fabrics, and applications requiring a smooth finish. Choosing between textured and flat polyester depends on the desired fabric performance, aesthetic, and end-use requirements.

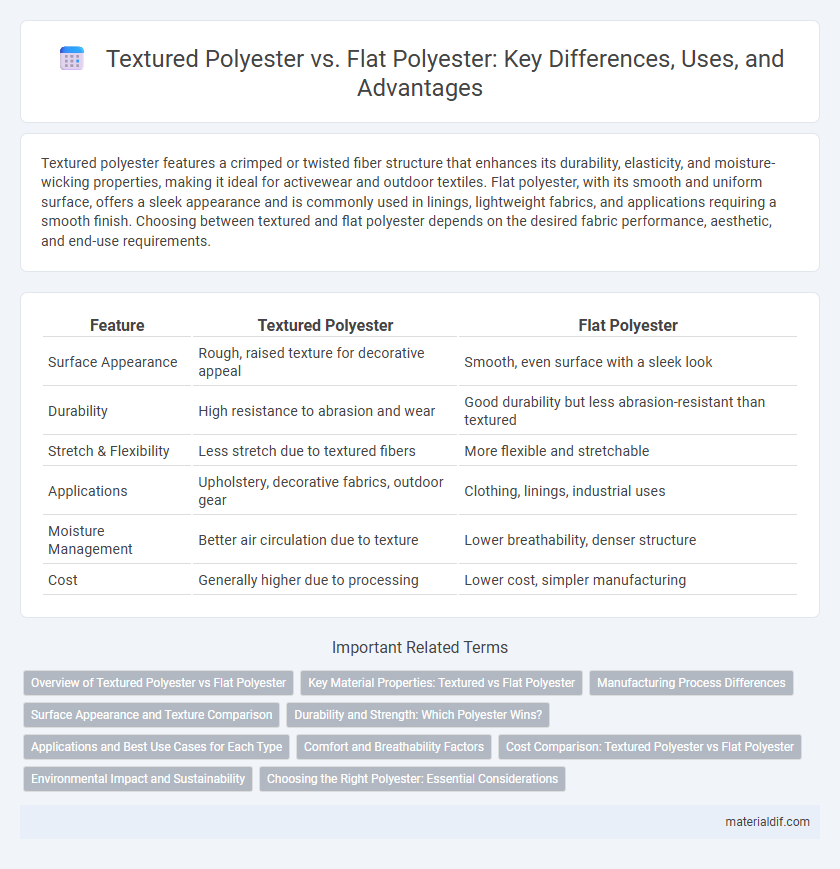

Table of Comparison

| Feature | Textured Polyester | Flat Polyester |

|---|---|---|

| Surface Appearance | Rough, raised texture for decorative appeal | Smooth, even surface with a sleek look |

| Durability | High resistance to abrasion and wear | Good durability but less abrasion-resistant than textured |

| Stretch & Flexibility | Less stretch due to textured fibers | More flexible and stretchable |

| Applications | Upholstery, decorative fabrics, outdoor gear | Clothing, linings, industrial uses |

| Moisture Management | Better air circulation due to texture | Lower breathability, denser structure |

| Cost | Generally higher due to processing | Lower cost, simpler manufacturing |

Overview of Textured Polyester vs Flat Polyester

Textured polyester fibers feature a crimped or twisted structure, enhancing elasticity, bulk, and moisture-wicking properties compared to flat polyester, which has a smooth, straight filament ideal for a sleek, tightly woven fabric appearance. Textured polyester is commonly used in activewear and upholstery for its breathability and comfort, while flat polyester suits applications requiring durability and a glossy finish like linings and outdoor fabrics. The choice between textured and flat polyester depends on the desired fabric performance, aesthetic, and end-use functionality.

Key Material Properties: Textured vs Flat Polyester

Textured polyester fibers exhibit increased bulk and elasticity compared to flat polyester, resulting in enhanced moisture-wicking and breathability suitable for activewear and performance textiles. Flat polyester fibers provide a smooth, sleek surface that offers high tensile strength and durability, making them ideal for formal garments and upholstery. The crimped structure of textured polyester creates more air pockets, improving insulation, while flat polyester's compact surface promotes stain resistance and ease of care.

Manufacturing Process Differences

Textured polyester fibers undergo a specialized manufacturing process that includes air-jet or false-twist texturizing techniques, which introduce crimps or loops to create bulk and elasticity. In contrast, flat polyester fibers are produced through a straightforward melt-spinning method, resulting in smooth, continuous filaments without additional texturing. The difference in processing impacts the fiber's physical properties, with textured polyester offering enhanced stretch, softness, and insulation compared to the denser, less flexible flat polyester.

Surface Appearance and Texture Comparison

Textured polyester exhibits a raised, tactile surface with a three-dimensional appearance, enhancing fabric breathability and providing a more dynamic look compared to flat polyester. Flat polyester has a smooth, uniform surface that offers a sleek, glossy finish, making it ideal for formal wear and applications requiring a polished aesthetic. The choice between textured and flat polyester impacts fabric feel, moisture-wicking properties, and overall garment visual appeal.

Durability and Strength: Which Polyester Wins?

Textured polyester offers enhanced durability and strength compared to flat polyester due to its increased surface area and resilience against wear and tear. The crimped fibers in textured polyester provide better elasticity and resistance to abrasion, making it ideal for heavy-duty applications. Flat polyester, while smooth and lightweight, generally lacks the same toughness and longevity, leading to quicker degradation under stress.

Applications and Best Use Cases for Each Type

Textured polyester fibers, with their enhanced bulk and elasticity, are ideal for applications requiring stretch and resilience such as athletic wear, upholstery, and outdoor fabrics, providing comfort and durability. Flat polyester fibers, characterized by their smooth surface and superior sheen, are best suited for formal garments, linings, and industrial uses where a sleek appearance and strength are prioritized. Selecting between textured and flat polyester depends on specific performance needs like breathability, texture, and fabric appearance, optimizing functionality across diverse textile applications.

Comfort and Breathability Factors

Textured polyester fibers create a bulky, airy fabric structure that enhances moisture-wicking capabilities and airflow, significantly improving comfort and breathability compared to flat polyester. Flat polyester fibers result in a denser, smoother texture that tends to trap heat and moisture, making it less breathable and potentially less comfortable for prolonged wear. The increased surface area of textured polyester promotes better ventilation and skin dryness, ideal for activewear and humid conditions.

Cost Comparison: Textured Polyester vs Flat Polyester

Textured polyester typically incurs higher manufacturing costs due to additional processing steps like air texturing or false twisting, resulting in greater energy consumption and labor expenses compared to flat polyester. Flat polyester production is more straightforward, relying on simpler extrusion and cooling processes, which generally lowers raw material usage and operational costs. As a result, textured polyester products tend to be priced higher than flat polyester alternatives in both wholesale and retail markets.

Environmental Impact and Sustainability

Textured polyester, created through physical modification processes, generally consumes more energy and water during production compared to flat polyester, increasing its environmental impact. Flat polyester, produced without extensive texturizing, typically requires fewer resources and emits less CO2, making it a more sustainable choice. Both types contribute to microplastic pollution, but innovations in recycling and bio-based polyester options are critical for reducing overall environmental harm.

Choosing the Right Polyester: Essential Considerations

Textured polyester offers enhanced breathability and wrinkle resistance, making it ideal for activewear and casual garments, whereas flat polyester provides a smoother, shinier finish suited for formal attire and linings. Key considerations include desired fabric appearance, durability requirements, and tactile comfort, as textured polyester often delivers greater moisture-wicking capabilities. Evaluating these factors ensures selecting the right polyester variant aligns with specific garment performance and aesthetic needs.

Textured Polyester vs Flat Polyester Infographic

materialdif.com

materialdif.com