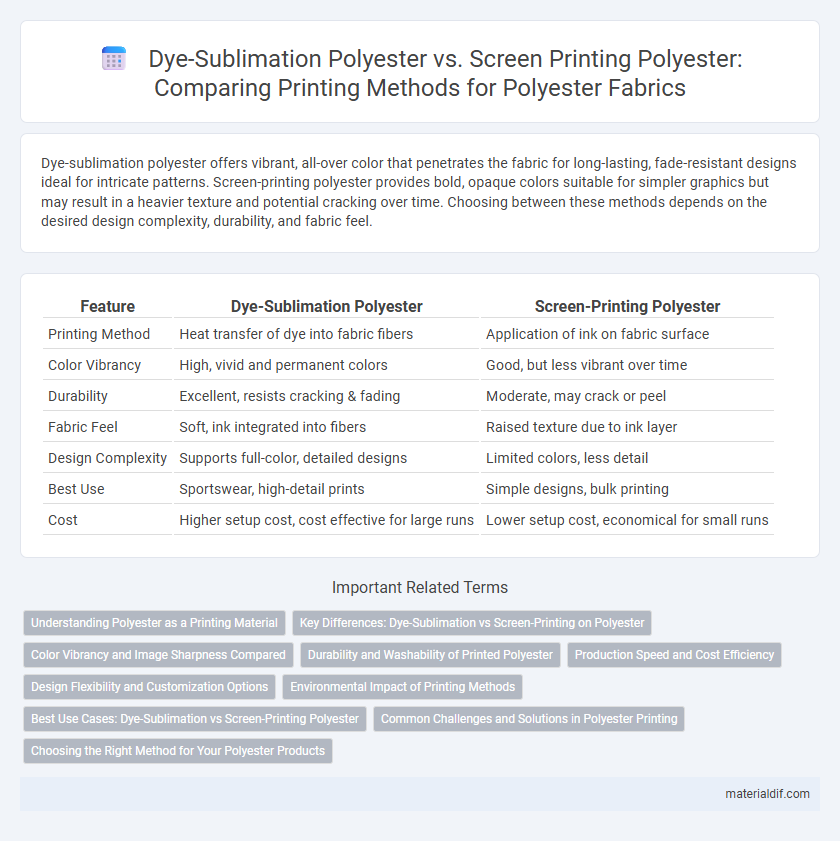

Dye-sublimation polyester offers vibrant, all-over color that penetrates the fabric for long-lasting, fade-resistant designs ideal for intricate patterns. Screen-printing polyester provides bold, opaque colors suitable for simpler graphics but may result in a heavier texture and potential cracking over time. Choosing between these methods depends on the desired design complexity, durability, and fabric feel.

Table of Comparison

| Feature | Dye-Sublimation Polyester | Screen-Printing Polyester |

|---|---|---|

| Printing Method | Heat transfer of dye into fabric fibers | Application of ink on fabric surface |

| Color Vibrancy | High, vivid and permanent colors | Good, but less vibrant over time |

| Durability | Excellent, resists cracking & fading | Moderate, may crack or peel |

| Fabric Feel | Soft, ink integrated into fibers | Raised texture due to ink layer |

| Design Complexity | Supports full-color, detailed designs | Limited colors, less detail |

| Best Use | Sportswear, high-detail prints | Simple designs, bulk printing |

| Cost | Higher setup cost, cost effective for large runs | Lower setup cost, economical for small runs |

Understanding Polyester as a Printing Material

Dye-sublimation polyester offers vibrant, long-lasting color by infusing ink directly into the fabric's fibers, ensuring high-resolution prints with excellent durability. Screen-printing on polyester provides bold, opaque layers of ink but may result in a heavier, less flexible finish that can crack over time. Understanding polyester's synthetic, hydrophobic properties highlights why dye-sublimation excels in moisture-wicking activewear, while screen-printing remains popular for bold designs on thicker garments.

Key Differences: Dye-Sublimation vs Screen-Printing on Polyester

Dye-sublimation on polyester involves infusing dye directly into the fabric fibers, resulting in vibrant, long-lasting colors that resist fading and cracking, ideal for detailed, full-color designs. Screen-printing on polyester applies ink layers on the fabric surface, offering bold and opaque prints but often limited in color gradient and prone to cracking over time. Dye-sublimation requires polyester or polyester-coated substrates for optimal color absorption, whereas screen-printing is more versatile in fabric compatibility but may suffer in durability and vibrancy on polyester materials.

Color Vibrancy and Image Sharpness Compared

Dye-sublimation polyester offers superior color vibrancy and image sharpness compared to screen-printing polyester, as the dye penetrates the fabric fibers for deeper, more vivid colors. Screen-printing polyester tends to have a thicker ink layer on the surface, which can result in less precise details and a slightly muted color palette. The continuous tone printing process of dye-sublimation produces smoother gradients and more detailed designs, making it ideal for high-resolution images on polyester fabrics.

Durability and Washability of Printed Polyester

Dye-sublimation polyester offers superior durability and washability compared to screen-printing polyester, as the dye chemically bonds with the fabric, preventing fading and cracking over multiple washes. Screen-printing polyester tends to have a thicker ink layer on the surface, which may peel or crack with repeated laundering and wear. This makes dye-sublimation the preferred method for long-lasting, vibrant prints on polyester garments subjected to frequent washing.

Production Speed and Cost Efficiency

Dye-sublimation polyester offers faster production speeds by enabling direct digital printing, eliminating the need for separate screens and setup times associated with screen-printing polyester. Cost efficiency improves with dye-sublimation as it reduces labor and material waste, particularly for small to medium runs and complex, color-rich designs. Screen-printing polyester remains cost-effective for large volume orders due to lower per-unit costs but involves longer setup times and higher initial investment.

Design Flexibility and Customization Options

Dye-sublimation polyester offers superior design flexibility with the ability to produce vibrant and complex full-color images that are embedded directly into the fabric, ensuring long-lasting, fade-resistant prints ideal for intricate patterns and gradients. Screen-printing polyester, while cost-effective for bulk orders, provides limited color options and is best suited for simpler designs with fewer colors due to its reliance on layering inks. Customization options are more expansive with dye-sublimation, enabling seamless prints over large areas without compromising fabric breathability, unlike screen-printing which can cause heavier, less flexible areas on the garment.

Environmental Impact of Printing Methods

Dye-sublimation printing on polyester uses water-based inks and minimal waste, making it a more eco-friendly option compared to screen-printing, which involves plastisol inks containing PVC and requires significant water for cleaning. The energy consumption in dye-sublimation is generally lower, and the absence of harmful solvents reduces environmental pollution. Screen-printing also generates more chemical waste and non-recyclable materials, contributing to a higher environmental footprint in textile production.

Best Use Cases: Dye-Sublimation vs Screen-Printing Polyester

Dye-sublimation polyester excels in producing vibrant, full-color designs ideal for athletic wear, promotional items, and custom apparel with intricate patterns due to its ability to infuse ink directly into fabric fibers. Screen-printing polyester suits large runs of bold, solid-color graphics on garments like team uniforms and branded merchandise, known for durability and cost-effectiveness in simple designs. Choosing between dye-sublimation and screen-printing depends on factors such as design complexity, production volume, color vibrancy, and fabric breathability requirements.

Common Challenges and Solutions in Polyester Printing

Dye-sublimation polyester offers vibrant, long-lasting colors but often faces challenges such as color fading and limited fabric compatibility, addressed by using high-quality sublimation inks and pre-treated polyester blends. Screen-printing polyester typically struggles with ink adhesion and cracking due to polyester's smooth surface, which can be minimized by selecting specialized plastisol or water-based inks and optimizing curing temperatures. Both methods benefit from thorough fabric pretreatment and precise temperature control to enhance print durability and color vibrancy on polyester textiles.

Choosing the Right Method for Your Polyester Products

Dye-sublimation polyester offers vibrant, long-lasting colors by infusing ink directly into the fabric, making it ideal for detailed, full-color designs on light-colored polyester items. Screen-printing polyester provides bold, opaque prints with excellent durability, suitable for large runs and designs with fewer colors or on darker fabrics. Selecting the right method depends on design complexity, color quantity, fabric color, production volume, and desired print longevity for your polyester products.

Dye-Sublimation Polyester vs Screen-Printing Polyester Infographic

materialdif.com

materialdif.com