Polyester with PVC coating offers superior water resistance and durability, making it ideal for heavy-duty applications such as outdoor gear and tarps. Polyester with PU coating provides better breathability and flexibility, enhancing comfort and making it suitable for clothing and lightweight bags. Both coatings enhance polyester's functionality, but the choice depends on the specific performance requirements of the end product.

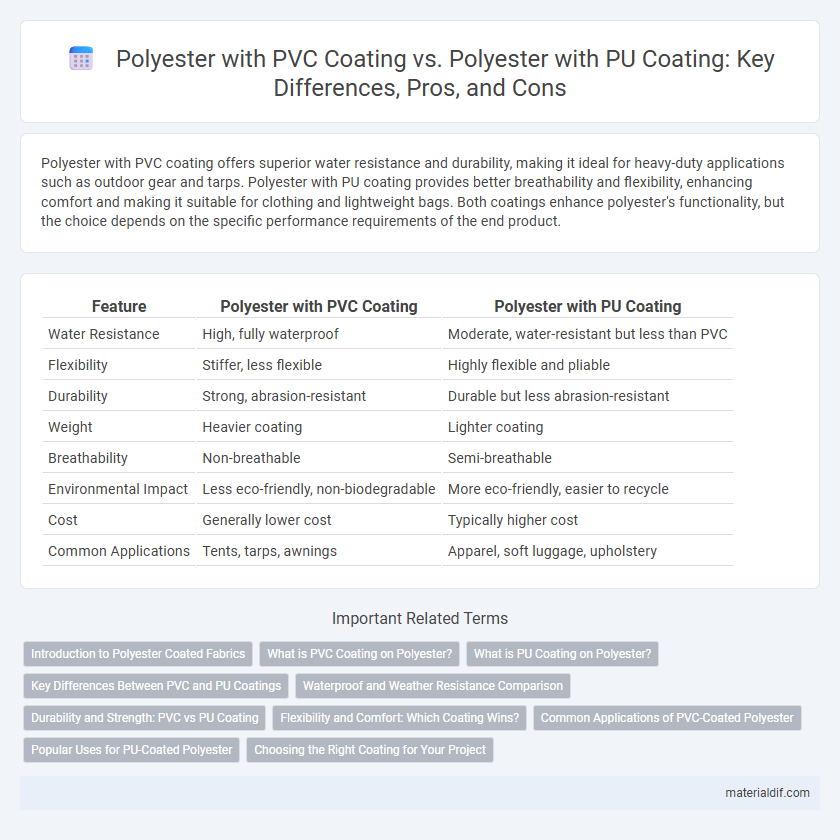

Table of Comparison

| Feature | Polyester with PVC Coating | Polyester with PU Coating |

|---|---|---|

| Water Resistance | High, fully waterproof | Moderate, water-resistant but less than PVC |

| Flexibility | Stiffer, less flexible | Highly flexible and pliable |

| Durability | Strong, abrasion-resistant | Durable but less abrasion-resistant |

| Weight | Heavier coating | Lighter coating |

| Breathability | Non-breathable | Semi-breathable |

| Environmental Impact | Less eco-friendly, non-biodegradable | More eco-friendly, easier to recycle |

| Cost | Generally lower cost | Typically higher cost |

| Common Applications | Tents, tarps, awnings | Apparel, soft luggage, upholstery |

Introduction to Polyester Coated Fabrics

Polyester coated fabrics combine the durability and strength of polyester fibers with protective surface layers, enhancing resistance to water, abrasion, and chemicals. Polyester with PVC coating offers excellent waterproofing and is widely used in outdoor applications due to its robust and heavy-duty nature. In contrast, polyester with PU coating provides greater flexibility, breathability, and lighter weight, making it suitable for apparel and soft luggage where comfort and ease of movement are prioritized.

What is PVC Coating on Polyester?

PVC coating on polyester involves applying a durable layer of polyvinyl chloride to the fabric, enhancing water resistance, flexibility, and abrasion protection. The coating forms a tough, waterproof barrier, making it ideal for outdoor applications like tarps, tents, and protective covers. PVC-coated polyester typically offers greater chemical resistance and durability compared to PU-coated polyester, but it can be heavier and less breathable.

What is PU Coating on Polyester?

PU coating on polyester involves applying a polyurethane layer that enhances fabric flexibility, water resistance, and durability, making it suitable for outdoor gear and sportswear. Compared to PVC coating, PU is softer, more breathable, and environmentally friendly while maintaining excellent abrasion resistance. Its lightweight and elastic properties improve comfort without compromising the fabric's protective qualities.

Key Differences Between PVC and PU Coatings

Polyester with PVC coating offers superior waterproofing and chemical resistance due to the dense, plasticized nature of polyvinyl chloride, making it ideal for heavy-duty outdoor applications. In contrast, polyester with PU coating provides enhanced flexibility and breathability, which suits garments and equipment requiring comfort alongside durability. PU coatings generally weigh less and maintain better elasticity at varying temperatures, while PVC coatings excel in abrasion resistance and longevity under harsh environmental conditions.

Waterproof and Weather Resistance Comparison

Polyester with PVC coating offers superior waterproofing due to its dense, non-porous surface that effectively blocks water penetration, making it ideal for heavy rain conditions. Polyester with PU coating provides excellent weather resistance by maintaining flexibility in varying temperatures and resisting UV degradation, ensuring long-term performance in outdoor environments. While PVC excels in waterproofing, PU delivers a balanced combination of water resistance and enhanced durability against weather-induced wear.

Durability and Strength: PVC vs PU Coating

Polyester with PVC coating offers superior durability and resistance to abrasion, chemicals, and weather conditions, making it ideal for heavy-duty applications. In contrast, polyester with PU coating provides excellent flexibility and tensile strength while maintaining moderate durability, suited for lighter, more flexible uses. PVC coatings typically have a thicker layer that enhances overall toughness, whereas PU coatings prioritize elasticity and comfort over extreme durability.

Flexibility and Comfort: Which Coating Wins?

Polyester with PU coating offers superior flexibility and comfort compared to polyester with PVC coating, due to its softer, more breathable finish that allows better movement and reduces stiffness. PVC-coated polyester tends to be more rigid and less breathable, making it less comfortable for prolonged wear or applications requiring frequent bending. For enhanced comfort and flexibility, PU-coated polyester is the preferred choice in textiles and apparel.

Common Applications of PVC-Coated Polyester

PVC-coated polyester is widely used in applications requiring high durability and weather resistance, such as outdoor tarpaulins, awnings, and inflatable structures. Its excellent waterproofing and UV resistance make it ideal for truck covers, tents, and banners exposed to harsh environmental conditions. The robust nature of PVC coatings provides enhanced protection against abrasion and chemicals, making it preferable over PU-coated polyester in heavy-duty and industrial uses.

Popular Uses for PU-Coated Polyester

PU-coated polyester is widely used in outdoor gear, rainwear, and upholstery due to its superior flexibility, breathability, and water resistance compared to PVC-coated polyester. This coating enhances comfort and durability, making it ideal for activewear, tents, and sports equipment. In contrast, PVC-coated polyester is typically favored for industrial applications requiring stronger chemical resistance and heavier waterproofing.

Choosing the Right Coating for Your Project

Choosing between polyester with PVC coating and polyester with PU coating depends on your project's specific requirements such as durability, flexibility, and weather resistance. PVC-coated polyester offers superior waterproofing and abrasion resistance, ideal for heavy-duty outdoor applications, while PU-coated polyester provides better breathability and stretch, suitable for lighter, flexible uses. Assess factors like cost, lifespan, and environmental exposure to determine the optimal coating for enhanced performance and longevity.

Polyester With PVC Coating vs Polyester With PU Coating Infographic

materialdif.com

materialdif.com