Polyester staple fiber consists of short, cut fibers that are spun together to create yarn, offering softness and warmth ideal for textiles like blankets and upholstery. Polyester filament fiber, made from continuous long strands, provides strength, smoothness, and sheen, making it suitable for high-performance fabrics and industrial applications. Choosing between these fibers depends on the desired texture, durability, and end-use of the polyester product.

Table of Comparison

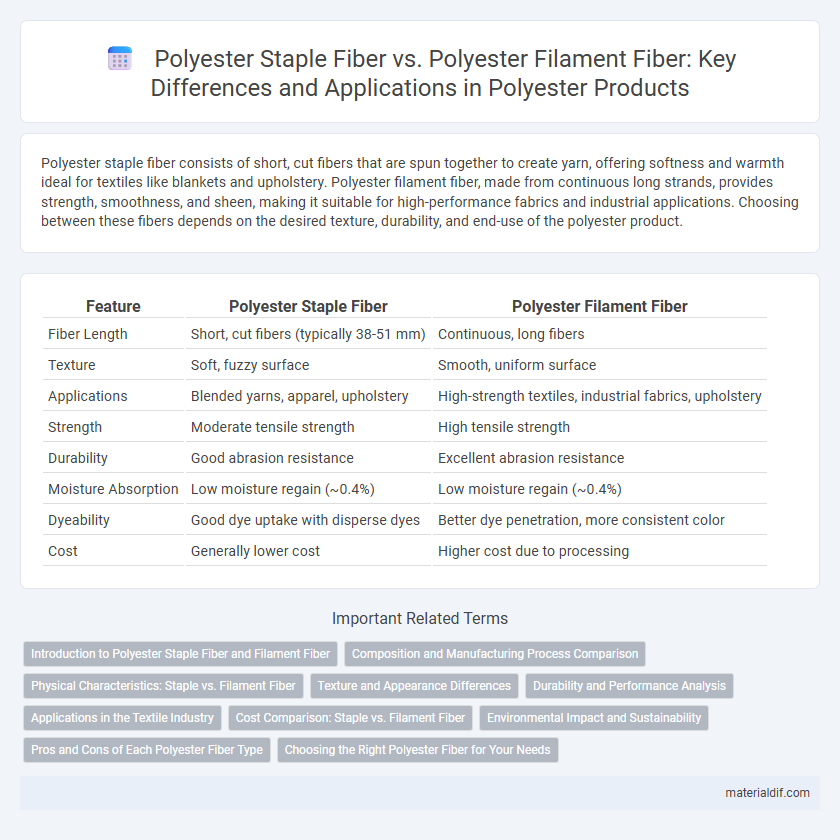

| Feature | Polyester Staple Fiber | Polyester Filament Fiber |

|---|---|---|

| Fiber Length | Short, cut fibers (typically 38-51 mm) | Continuous, long fibers |

| Texture | Soft, fuzzy surface | Smooth, uniform surface |

| Applications | Blended yarns, apparel, upholstery | High-strength textiles, industrial fabrics, upholstery |

| Strength | Moderate tensile strength | High tensile strength |

| Durability | Good abrasion resistance | Excellent abrasion resistance |

| Moisture Absorption | Low moisture regain (~0.4%) | Low moisture regain (~0.4%) |

| Dyeability | Good dye uptake with disperse dyes | Better dye penetration, more consistent color |

| Cost | Generally lower cost | Higher cost due to processing |

Introduction to Polyester Staple Fiber and Filament Fiber

Polyester staple fiber consists of short, cut lengths of synthetic fibers typically measuring 3 to 6 inches, commonly used in woven and knitted fabrics for apparel and upholstery due to its softness and ease of blending with natural fibers. Polyester filament fiber, on the other hand, features continuous, long fibers that provide excellent strength, durability, and a smooth texture, making it ideal for high-performance textiles, industrial applications, and fine fabrics. The distinction between staple and filament polyester fibers lies in their length and end-use, impacting fabric texture, strength, and manufacturing processes.

Composition and Manufacturing Process Comparison

Polyester staple fiber is composed of short, cut segments of polyethylene terephthalate (PET) created by cutting spun filaments, whereas polyester filament fiber consists of continuous, long strands of PET directly extruded from polymer chips during melt spinning. The manufacturing process of staple fibers involves spinning, drawing, and then cutting into staple lengths, enabling blending with natural fibers for versatility in textile applications, whereas filament fibers undergo melt spinning and drawing without cutting, resulting in smoother, stronger yarns ideal for high-performance fabrics. Both types utilize PET polymer but differ significantly in processing methods, influencing fiber length, texture, and end-use functionality.

Physical Characteristics: Staple vs. Filament Fiber

Polyester staple fibers are short fibers typically measuring 38 to 51 millimeters, offering a soft, fluffy texture ideal for blending with natural fibers and creating bulkier, breathable fabrics. Polyester filament fibers are continuous, long strands that provide smoother, stronger, and more lustrous fabrics with higher tensile strength and better resistance to abrasion. Staple fibers result in textured, matte finishes, while filament fibers produce sleek, shiny textiles suitable for high-performance garments and technical applications.

Texture and Appearance Differences

Polyester staple fiber features a soft, matte texture with a fuzzy appearance due to its short fibers, making it ideal for producing fabrics with warmth and bulk. Polyester filament fiber, composed of continuous long strands, offers a smoother, shinier finish with a sleek and uniform look, enhancing durability and luster in textiles. These differences influence the choice of fiber based on desired fabric aesthetics and tactile qualities in applications like apparel and upholstery.

Durability and Performance Analysis

Polyester staple fiber offers enhanced durability due to its shorter fiber length, which provides greater resistance to abrasion and pilling in textile applications. In contrast, polyester filament fiber, characterized by continuous long strands, delivers superior tensile strength and smooth texture, making it ideal for high-performance fabrics requiring elasticity and resilience. Performance analysis shows that while staple fibers excel in comfort and durability for everyday wear, filament fibers dominate in technical textiles where longevity and strength are critical.

Applications in the Textile Industry

Polyester staple fiber is widely used in the production of spun yarns for apparel, home textiles, and upholstery due to its softness and versatility, making it ideal for blending with natural fibers like cotton and wool. Polyester filament fiber, characterized by continuous, smooth strands, is predominantly used in industrial applications such as weaving for fabrics with high strength, durability, and resistance to abrasion, as seen in garments, technical textiles, and automotive interiors. The textile industry leverages the distinct properties of both fibers to optimize fabric performance, balancing comfort and durability across diverse applications.

Cost Comparison: Staple vs. Filament Fiber

Polyester staple fiber typically incurs higher production costs due to its additional processing steps, such as cutting the filaments into short lengths and blending with other fibers, which increases labor and machinery expenses. In contrast, polyester filament fiber is produced continuously and more efficiently, resulting in lower manufacturing costs and better price competitiveness. As a result, filament fibers often provide cost advantages for applications requiring uniform texture and strength, while staple fibers offer premium quality for textile blends at a relatively higher cost.

Environmental Impact and Sustainability

Polyester staple fiber and polyester filament fiber differ significantly in environmental impact and sustainability, with staple fibers generally requiring more energy-intensive processing due to shorter fiber lengths. Filament fibers, consisting of continuous strands, enable more efficient manufacturing with less waste and reduced water consumption, making them relatively more sustainable. However, both types contribute to microplastic pollution and rely heavily on non-renewable petroleum resources, underscoring the need for recycling innovations and alternative bio-based polyester sources.

Pros and Cons of Each Polyester Fiber Type

Polyester staple fiber offers excellent versatility and softness, making it ideal for blended fabrics and comfortable apparel, but it tends to have lower tensile strength compared to filament fibers. Polyester filament fiber provides superior strength, durability, and smoothness, which enhances fabric luster and resistance to abrasion, though it is less breathable and can feel less natural against the skin. Choosing between staple and filament polyester depends on application requirements such as fabric texture, strength, and comfort.

Choosing the Right Polyester Fiber for Your Needs

Polyester staple fiber, composed of short, cut fibers, offers excellent softness and breathability, making it ideal for apparel and home textiles. Polyester filament fiber consists of continuous, long strands that provide superior strength, durability, and smoothness, suitable for industrial applications and high-performance fabrics. Selecting between staple and filament polyester fibers depends on the desired texture, strength, and end-use requirements of your project.

Polyester staple fiber vs Polyester filament fiber Infographic

materialdif.com

materialdif.com