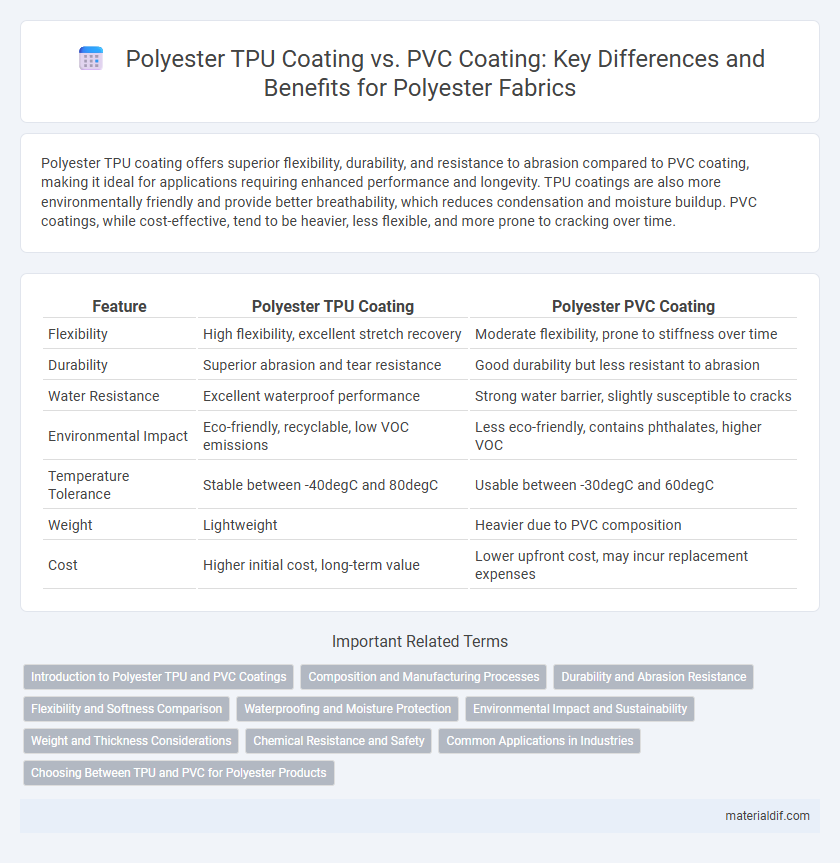

Polyester TPU coating offers superior flexibility, durability, and resistance to abrasion compared to PVC coating, making it ideal for applications requiring enhanced performance and longevity. TPU coatings are also more environmentally friendly and provide better breathability, which reduces condensation and moisture buildup. PVC coatings, while cost-effective, tend to be heavier, less flexible, and more prone to cracking over time.

Table of Comparison

| Feature | Polyester TPU Coating | Polyester PVC Coating |

|---|---|---|

| Flexibility | High flexibility, excellent stretch recovery | Moderate flexibility, prone to stiffness over time |

| Durability | Superior abrasion and tear resistance | Good durability but less resistant to abrasion |

| Water Resistance | Excellent waterproof performance | Strong water barrier, slightly susceptible to cracks |

| Environmental Impact | Eco-friendly, recyclable, low VOC emissions | Less eco-friendly, contains phthalates, higher VOC |

| Temperature Tolerance | Stable between -40degC and 80degC | Usable between -30degC and 60degC |

| Weight | Lightweight | Heavier due to PVC composition |

| Cost | Higher initial cost, long-term value | Lower upfront cost, may incur replacement expenses |

Introduction to Polyester TPU and PVC Coatings

Polyester TPU coating offers superior elasticity, abrasion resistance, and breathability compared to PVC coating, making it ideal for flexible and high-performance textile applications. PVC coating is known for its cost-effectiveness, waterproofing capabilities, and durability, often used in industrial and heavy-duty fabrics. Both coatings enhance the base polyester fabric, but TPU provides enhanced flexibility and environmental benefits, whereas PVC is valued for its robust protection and affordability.

Composition and Manufacturing Processes

Polyester TPU coating consists of thermoplastic polyurethane, which offers flexibility and durability through a polymerization process involving diisocyanates and polyols, resulting in a highly elastic and abrasion-resistant finish. PVC coating is created by applying polyvinyl chloride resin combined with plasticizers and stabilizers in a heated calendaring or dipping process, producing a rigid and water-resistant layer. The manufacturing process of TPU coatings emphasizes solvent or melt processing for seamless and breathable surfaces, while PVC coatings rely on solvent-based or hot-melt techniques yielding heavier, less breathable materials.

Durability and Abrasion Resistance

Polyester TPU coating offers superior durability and abrasion resistance compared to PVC coating, making it ideal for high-performance applications. TPU coatings exhibit excellent flexibility, resistance to cracking, and maintain integrity under stress, whereas PVC coatings tend to become brittle over time and degrade faster under abrasive conditions. The enhanced wear resistance of polyester TPU ensures longer lifespan and better protection against environmental factors compared to traditional PVC-coated fabrics.

Flexibility and Softness Comparison

Polyester TPU coating offers superior flexibility and softness compared to PVC coating, making it ideal for applications requiring high pliability and comfort. TPU coatings maintain their elasticity over a wide temperature range, enhancing durability and wear resistance without compromising softness. In contrast, PVC coatings tend to be stiffer and less breathable, which can reduce flexibility and overall user comfort in prolonged use.

Waterproofing and Moisture Protection

Polyester TPU coating offers superior waterproofing and moisture protection compared to PVC coating due to its excellent elasticity and resistance to water penetration. TPU coatings maintain durability under extreme weather conditions and repeated flexing, preventing water ingress more effectively than rigid PVC layers. This makes polyester TPU-coated fabrics ideal for high-performance outdoor gear and waterproof apparel demanding sustained moisture barrier properties.

Environmental Impact and Sustainability

Polyester TPU coating offers superior environmental benefits compared to PVC coating, as it is more easily recyclable and contains no harmful chlorine compounds, reducing toxic emissions during production and disposal. TPU coatings exhibit lower carbon footprints and generate fewer hazardous waste materials, supporting sustainable manufacturing practices. The biodegradability and reduced chemical leaching of TPU emphasize its growing preference for eco-conscious applications over traditional PVC coatings.

Weight and Thickness Considerations

Polyester TPU coatings typically weigh less and offer thinner layers compared to PVC coatings, making them ideal for applications requiring lightweight and flexible materials. TPU coatings provide superior abrasion resistance and durability with reduced thickness, enhancing comfort and performance without sacrificing strength. In contrast, PVC coatings tend to be heavier and thicker, which can add bulk and reduce flexibility in certain polyester fabric applications.

Chemical Resistance and Safety

Polyester TPU coating offers superior chemical resistance compared to PVC coating, effectively withstanding exposure to oils, acids, and solvents without degradation. TPU is also non-toxic and free from harmful phthalates, making it a safer option for applications in food packaging and medical devices. PVC coatings often contain plasticizers that can leach harmful chemicals, posing environmental and health risks.

Common Applications in Industries

Polyester TPU coating is widely used in the textile and automotive industries for its flexibility, durability, and breathability, making it ideal for sportswear, protective clothing, and inflatable products. In contrast, PVC coating is common in construction and marine industries due to its excellent weather resistance, water impermeability, and cost-effectiveness, often applied in tarpaulins, banners, and inflatable boats. Both coatings enhance polyester fabrics but serve distinct functions aligned with industry-specific demands.

Choosing Between TPU and PVC for Polyester Products

TPU coating offers superior flexibility, abrasion resistance, and environmental friendliness compared to PVC coating on polyester products. PVC coatings provide excellent waterproofing and cost-effectiveness but tend to be less durable and more rigid than TPU. Selecting between TPU and PVC depends on the specific application needs, balancing factors like durability, flexibility, environmental impact, and budget.

Polyester TPU Coating vs PVC Coating Infographic

materialdif.com

materialdif.com