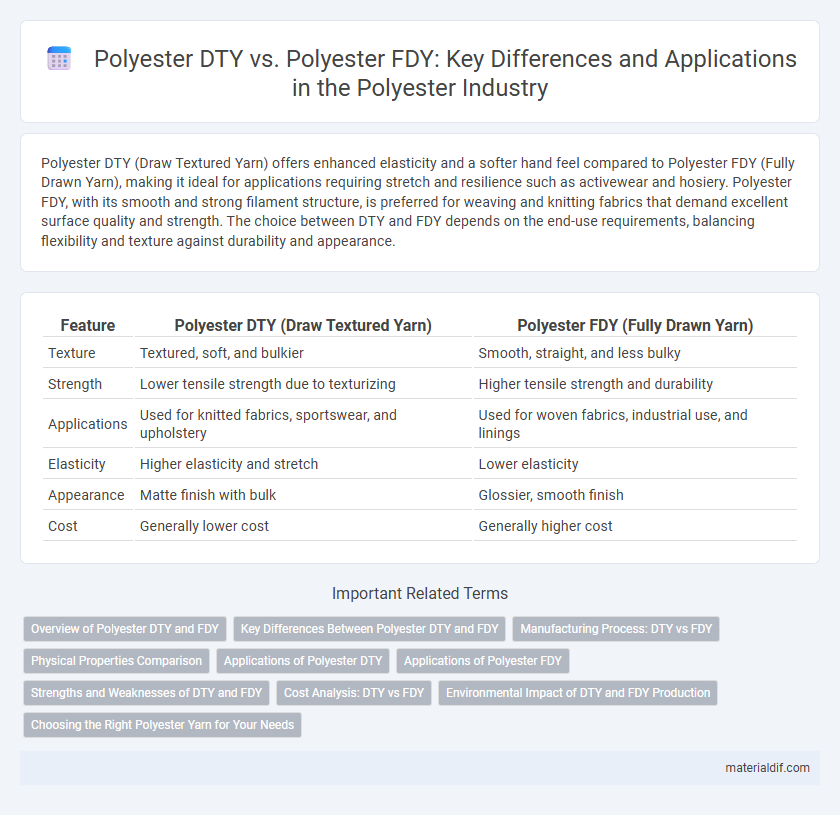

Polyester DTY (Draw Textured Yarn) offers enhanced elasticity and a softer hand feel compared to Polyester FDY (Fully Drawn Yarn), making it ideal for applications requiring stretch and resilience such as activewear and hosiery. Polyester FDY, with its smooth and strong filament structure, is preferred for weaving and knitting fabrics that demand excellent surface quality and strength. The choice between DTY and FDY depends on the end-use requirements, balancing flexibility and texture against durability and appearance.

Table of Comparison

| Feature | Polyester DTY (Draw Textured Yarn) | Polyester FDY (Fully Drawn Yarn) |

|---|---|---|

| Texture | Textured, soft, and bulkier | Smooth, straight, and less bulky |

| Strength | Lower tensile strength due to texturizing | Higher tensile strength and durability |

| Applications | Used for knitted fabrics, sportswear, and upholstery | Used for woven fabrics, industrial use, and linings |

| Elasticity | Higher elasticity and stretch | Lower elasticity |

| Appearance | Matte finish with bulk | Glossier, smooth finish |

| Cost | Generally lower cost | Generally higher cost |

Overview of Polyester DTY and FDY

Polyester DTY (Draw Textured Yarn) is a highly versatile filament yarn characterized by its textured surface, offering enhanced elasticity, softness, and bulk, making it ideal for applications such as knitted fabrics, sportswear, and upholstery. Polyester FDY (Fully Drawn Yarn) is a smooth, high-tenacity filament yarn with excellent strength, durability, and dimensional stability, commonly used in weaving, industrial textiles, and as a base for further processing like texturizing. Both DTY and FDY are manufactured from PET (polyethylene terephthalate) but differ mainly in their processing methods and end-use properties, with DTY favored for stretch and comfort and FDY recognized for its strength and smoothness.

Key Differences Between Polyester DTY and FDY

Polyester DTY (Draw Textured Yarn) is produced by drawing and texturizing FDY (Fully Drawn Yarn), resulting in a yarn with increased elasticity, bulk, and a textured appearance ideal for knitwear and apparel. In contrast, Polyester FDY is a smoother, stronger yarn with higher dimensional stability, commonly used for woven fabrics and industrial applications requiring uniformity and firmness. The key differences lie in their processing methods, physical properties, and end-use suitability, with DTY offering enhanced stretch and texture while FDY provides superior strength and smoothness.

Manufacturing Process: DTY vs FDY

Polyester DTY (Draw Textured Yarn) undergoes a complex process involving drawing, twisting, and texturizing to create yarn with enhanced elasticity, bulk, and texture, suitable for fabrics requiring stretch and softness. In contrast, Polyester FDY (Fully Drawn Yarn) is produced through a simpler procedure where filaments are drawn and cooled directly after extrusion, resulting in smooth, fine, and lustrous yarn with high tensile strength. The manufacturing distinction impacts the final yarn characteristics, making DTY ideal for textured, durable textiles, while FDY suits applications needing smoothness and uniformity.

Physical Properties Comparison

Polyester DTY (Draw Textured Yarn) exhibits higher elasticity and bulkiness compared to Polyester FDY (Fully Drawn Yarn), making DTY more suitable for stretchable and textured fabric applications. FDY has superior strength, smoothness, and luster due to its continuous filament structure, ideal for lightweight and sheer textile products. The physical differences in filament structure lead to distinct tensile strength and elongation characteristics, influencing their performance in various fabric manufacturing processes.

Applications of Polyester DTY

Polyester DTY (Draw Textured Yarn) is widely used in activewear, sportswear, and fashion apparel due to its excellent stretchability and textured appearance, which provides enhanced comfort and aesthetic appeal. It is also favored in home textiles such as upholstery and curtains for its durability and wrinkle resistance. Compared to Polyester FDY (Fully Drawn Yarn), DTY offers better elasticity and bulk, making it ideal for applications requiring flexibility and softness.

Applications of Polyester FDY

Polyester FDY (Fully Drawn Yarn) is widely used in the production of high-quality fabrics for apparel, home textiles, and industrial uses due to its superior strength, smooth texture, and excellent dyeability. Common applications include knitwear, woven fabrics, linings, curtains, and upholstery, where durability and aesthetic appeal are essential. The consistent filament length and tensile strength of FDY make it ideal for creating lightweight, breathable, and wrinkle-resistant textile products.

Strengths and Weaknesses of DTY and FDY

Polyester Draw Textured Yarn (DTY) offers excellent stretchability and softness, making it ideal for fabrics requiring elasticity and better hand feel, but it may have lower tensile strength compared to FDY. Polyester Fully Drawn Yarn (FDY) has superior tensile strength and smooth texture, providing durability and high resistance to wear, yet it lacks the elasticity and bulkiness found in DTY. Choosing between DTY and FDY depends on the desired fabric performance, balancing DTY's flexibility against FDY's robustness.

Cost Analysis: DTY vs FDY

Polyester DTY (Draw Textured Yarn) typically incurs higher production costs compared to Polyester FDY (Fully Drawn Yarn) due to its complex processing steps like drawing and texturing. FDY is more cost-effective in mass production as it undergoes fewer processing stages, resulting in lower energy consumption and faster manufacturing times. The price difference between DTY and FDY reflects not only processing complexity but also their distinct applications in textiles, with DTY favored for stretch and durability and FDY for smooth, lightweight fabrics.

Environmental Impact of DTY and FDY Production

Polyester Draw Textured Yarn (DTY) production typically consumes more energy and water compared to Fully Drawn Yarn (FDY) due to the additional texturizing process, leading to a higher environmental footprint. FDY production is generally more environmentally friendly as it involves fewer processing steps, resulting in lower emissions and reduced chemical usage. Choosing FDY over DTY can significantly decrease the environmental impact associated with polyester fabric manufacturing, supporting more sustainable textile practices.

Choosing the Right Polyester Yarn for Your Needs

Polyester DTY (Draw Textured Yarn) offers enhanced elasticity, bulkiness, and breathability, making it ideal for stretchable apparel and activewear. Polyester FDY (Fully Drawn Yarn) provides superior strength, smoothness, and dimensional stability, suited for weaving applications and high-quality fabrics. Selecting between DTY and FDY depends on end-use requirements, such as the need for flexibility versus fabric firmness and durability.

Polyester DTY vs Polyester FDY Infographic

materialdif.com

materialdif.com