Woodfree paper is made from chemical pulp, resulting in a smoother, stronger, and more durable finish ideal for high-quality printing and writing. Mechanical paper, produced by grinding wood pulp, tends to have a higher lignin content, causing it to yellow and degrade faster over time. Choosing woodfree paper ensures better archival quality and resistance to aging compared to mechanical paper.

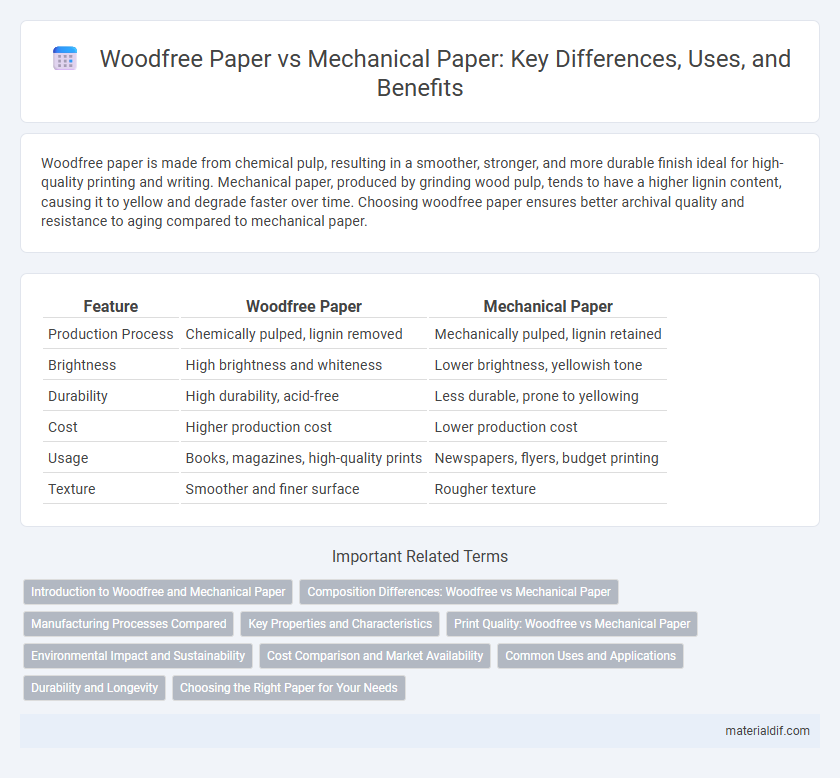

Table of Comparison

| Feature | Woodfree Paper | Mechanical Paper |

|---|---|---|

| Production Process | Chemically pulped, lignin removed | Mechanically pulped, lignin retained |

| Brightness | High brightness and whiteness | Lower brightness, yellowish tone |

| Durability | High durability, acid-free | Less durable, prone to yellowing |

| Cost | Higher production cost | Lower production cost |

| Usage | Books, magazines, high-quality prints | Newspapers, flyers, budget printing |

| Texture | Smoother and finer surface | Rougher texture |

Introduction to Woodfree and Mechanical Paper

Woodfree paper is produced using chemical pulping processes that remove lignin, resulting in higher brightness, improved durability, and smoother texture, making it ideal for high-quality printing and writing applications. Mechanical paper is manufactured by mechanically grinding wood, retaining most of the lignin, which leads to lower production costs but reduced paper strength and yellowing over time. Understanding the differences between woodfree and mechanical paper is essential for selecting the appropriate paper type based on quality, cost, and end-use requirements.

Composition Differences: Woodfree vs Mechanical Paper

Woodfree paper is composed primarily of chemical pulp, which removes lignin and results in higher brightness and durability, making it ideal for printing and writing purposes. Mechanical paper retains most of the wood's lignin due to its production from groundwood pulp, leading to lower brightness and strength but increased bulk and cost-efficiency. The chemical composition differences significantly affect the paper's quality, longevity, and suitability for various applications.

Manufacturing Processes Compared

Woodfree paper undergoes a chemical pulping process where lignin is removed, resulting in a smoother and more durable sheet ideal for high-quality printing. Mechanical paper is produced by mechanically grinding wood chips, preserving most lignin, which leads to faster, cost-effective manufacturing but lower brightness and durability. The chemical process in woodfree paper demands more energy and time, while mechanical paper offers higher yield with less processing complexity.

Key Properties and Characteristics

Woodfree paper contains chemically pulped fibers resulting in higher brightness, smoother surface, and greater durability, making it ideal for high-quality printing and writing. Mechanical paper, produced by grinding wood chips, retains more lignin, leading to lower brightness and faster yellowing but offers higher bulk and opacity at a lower cost. The choice between woodfree and mechanical paper depends on specific needs such as print quality, longevity, and budget constraints.

Print Quality: Woodfree vs Mechanical Paper

Woodfree paper offers superior print quality due to its higher purity and lack of lignin, resulting in brighter whites and sharper inks compared to mechanical paper. Mechanical paper contains lignin and wood fibers that darken over time, causing print colors to fade and appear less vibrant. The smooth surface of woodfree paper enhances ink absorption and detail precision, making it ideal for high-quality printing applications.

Environmental Impact and Sustainability

Woodfree paper, made primarily from chemical pulp, offers enhanced durability and brightness while generally having a higher environmental footprint due to energy-intensive processing and chemical usage. Mechanical paper, produced by grinding wood logs, consumes less energy and retains more lignin, leading to higher recyclability but shorter lifespan and potential yellowing over time. Sustainable forestry practices and advances in recycling technology are crucial in minimizing the environmental impact of both woodfree and mechanical paper types.

Cost Comparison and Market Availability

Woodfree paper typically costs more than mechanical paper due to its higher production expenses, including chemical pulping and bleaching processes. Mechanical paper is more widely available and cheaper because it uses groundwood pulp, which requires less processing and energy. Market trends show that woodfree paper dominates premium printing sectors, while mechanical paper remains prevalent in bulk packaging and newsprint due to lower cost and accessibility.

Common Uses and Applications

Woodfree paper, also known as uncoated free-sheet paper, is commonly used for high-quality printing applications such as books, magazines, and office stationery due to its smooth surface and durability. Mechanical paper, produced using groundwood pulp, is primarily utilized in newspapers, catalogs, and flyers where cost-efficiency and bulk production are prioritized over longevity and print sharpness. Both types serve distinct market needs, with woodfree paper favored for premium prints and mechanical paper dominating mass distribution media.

Durability and Longevity

Woodfree paper, made from chemical pulp, offers superior durability and longevity due to its higher cellulose content and reduced lignin, which minimizes yellowing and brittleness over time. Mechanical paper contains more lignin, causing faster degradation, discoloration, and reduced strength when exposed to light and air. As a result, woodfree paper is preferred for archival documents requiring long-term preservation.

Choosing the Right Paper for Your Needs

Woodfree paper, made from chemical pulp, offers higher brightness, superior print quality, and better durability, making it ideal for professional documents and publications. Mechanical paper, produced using groundwood pulp, is more cost-effective and environmentally friendly but tends to yellow and deteriorate faster, suitable for everyday printing and short-term use. Assessing factors like longevity, print clarity, and budget helps determine the appropriate paper choice for specific applications.

Woodfree Paper vs Mechanical Paper Infographic

materialdif.com

materialdif.com