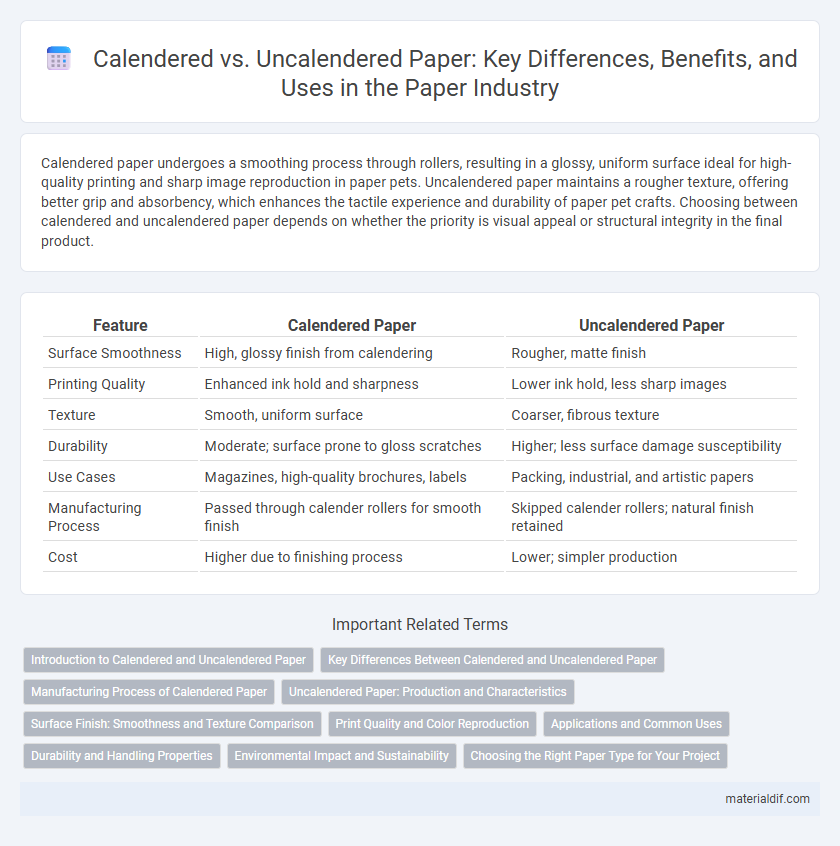

Calendered paper undergoes a smoothing process through rollers, resulting in a glossy, uniform surface ideal for high-quality printing and sharp image reproduction in paper pets. Uncalendered paper maintains a rougher texture, offering better grip and absorbency, which enhances the tactile experience and durability of paper pet crafts. Choosing between calendered and uncalendered paper depends on whether the priority is visual appeal or structural integrity in the final product.

Table of Comparison

| Feature | Calendered Paper | Uncalendered Paper |

|---|---|---|

| Surface Smoothness | High, glossy finish from calendering | Rougher, matte finish |

| Printing Quality | Enhanced ink hold and sharpness | Lower ink hold, less sharp images |

| Texture | Smooth, uniform surface | Coarser, fibrous texture |

| Durability | Moderate; surface prone to gloss scratches | Higher; less surface damage susceptibility |

| Use Cases | Magazines, high-quality brochures, labels | Packing, industrial, and artistic papers |

| Manufacturing Process | Passed through calender rollers for smooth finish | Skipped calender rollers; natural finish retained |

| Cost | Higher due to finishing process | Lower; simpler production |

Introduction to Calendered and Uncalendered Paper

Calendered paper undergoes a finishing process where it is passed through rollers to create a smooth, glossy surface ideal for high-quality printing and sharp image reproduction. Uncalendered paper retains a rougher, more natural texture, offering enhanced absorbency and a matte finish suited for applications requiring better ink adhesion or a rustic aesthetic. The distinction between calendered and uncalendered paper significantly affects print quality, tactile experience, and suitability for different printing techniques.

Key Differences Between Calendered and Uncalendered Paper

Calendered paper undergoes a finishing process where it is passed through rollers to create a smooth, glossy surface ideal for high-quality printing and detailed graphics. Uncalendered paper retains a rougher texture with more surface absorbency, making it suitable for applications requiring better ink adhesion or a matte finish. The key differences lie in surface smoothness, glossiness, and ink receptivity, influencing their optimal use in printing, packaging, and specialty paper products.

Manufacturing Process of Calendered Paper

Calendered paper undergoes a manufacturing process where the paper sheet passes through a series of hard pressure rollers, known as calenders, to smooth and compress the surface, enhancing gloss and uniformity. This process reduces surface roughness and improves printability, making calendered paper ideal for high-quality printing applications such as magazines and brochures. The calendering stage is typically performed after drying, applying controlled pressure and temperature to achieve the desired finish.

Uncalendered Paper: Production and Characteristics

Uncalendered paper is produced without passing through calender rolls, resulting in a rougher surface texture and higher thickness compared to calendered paper. Its porous structure enhances ink absorption, making it suitable for applications requiring strong adhesion and matte finishes. The absence of calendering preserves the natural fiber bulk, contributing to increased stiffness and printability in packaging and industrial uses.

Surface Finish: Smoothness and Texture Comparison

Calendered paper features a smooth, glossy surface achieved through multiple passes between heated rollers, enhancing its sheen and print clarity. Uncalendered paper retains a rougher, more textured finish, offering increased absorbency and a natural tactile feel ideal for artistic applications. The distinct surface characteristics directly impact ink adherence and visual sharpness, making calendered paper preferable for high-quality printing and uncalendered paper suitable for textured, uncoated needs.

Print Quality and Color Reproduction

Calendered paper exhibits a smooth, glossy surface achieved through high-pressure rollers, enhancing print quality by producing sharp images and vibrant color reproduction ideal for detailed graphics. Uncalendered paper maintains a rougher texture that absorbs ink differently, resulting in softer prints with more natural, muted colors but less precise detail. Choosing between calendered and uncalendered paper depends on the desired balance between crispness and tactile feel for print projects.

Applications and Common Uses

Calendered paper, with its smooth and glossy finish, is widely used for high-quality printing applications such as magazines, brochures, and photographic prints where vibrant color reproduction is essential. Uncalendered paper, featuring a rougher texture and higher absorbency, is preferred for uses like packaging, book covers, and writing paper where durability and ink absorption are prioritized. Industries such as publishing and packaging select between calendered and uncalendered paper based on the need for surface smoothness and print clarity versus tactile feel and strength.

Durability and Handling Properties

Calendered paper features a smooth, glossy surface achieved through a process of pressing and polishing, enhancing print quality but reducing durability and making it more prone to creasing and tearing during handling. Uncalendered paper retains a rougher texture and higher bulk, offering superior strength and resistance to wear, making it more suitable for applications requiring repeated handling or higher abrasion resistance. The choice between calendered and uncalendered paper depends on balancing the need for visual appeal against the requirement for durability and robust handling characteristics.

Environmental Impact and Sustainability

Calendered paper undergoes a mechanical process that compresses fibers, resulting in a smoother surface but increased energy consumption and higher carbon emissions compared to uncalendered paper. Uncalendered paper maintains a more natural fiber structure, allowing for better recyclability and reduced environmental footprint due to less processing. Choosing uncalendered paper supports sustainability goals by minimizing energy use and preserving fiber integrity, which enhances biodegradability and resource efficiency.

Choosing the Right Paper Type for Your Project

Calendered paper features a smooth, glossy finish achieved through high-pressure rollers, ideal for projects requiring sharp image quality and vibrant colors such as brochures and flyers. Uncalendered paper retains a rougher texture, enhancing ink absorption and providing a natural feel suitable for artistic prints and packaging materials. Selecting the appropriate paper depends on the desired visual effect and functional requirements, ensuring optimal print performance and project impact.

Calendered Paper vs Uncalendered Paper Infographic

materialdif.com

materialdif.com