Ivory board offers a smooth, glossy finish and higher durability, making it ideal for premium packaging and high-quality printing. Duplex board features a white, coated surface on one side with a grey back, providing cost-effective strength suitable for everyday packaging needs. Choosing between ivory and duplex boards depends on the desired appearance, budget, and functionality of the paper packaging.

Table of Comparison

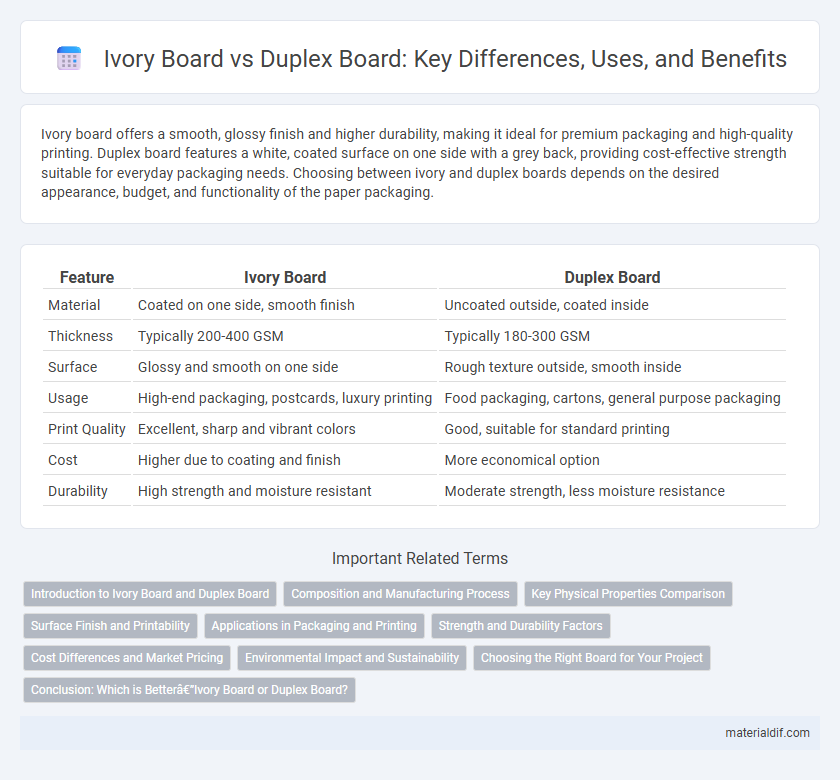

| Feature | Ivory Board | Duplex Board |

|---|---|---|

| Material | Coated on one side, smooth finish | Uncoated outside, coated inside |

| Thickness | Typically 200-400 GSM | Typically 180-300 GSM |

| Surface | Glossy and smooth on one side | Rough texture outside, smooth inside |

| Usage | High-end packaging, postcards, luxury printing | Food packaging, cartons, general purpose packaging |

| Print Quality | Excellent, sharp and vibrant colors | Good, suitable for standard printing |

| Cost | Higher due to coating and finish | More economical option |

| Durability | High strength and moisture resistant | Moderate strength, less moisture resistance |

Introduction to Ivory Board and Duplex Board

Ivory board is a high-quality, thick paperboard known for its smooth, glossy finish on one side, making it ideal for premium packaging and luxury print products. Duplex board consists of two layers of paper: a white, coated top layer and a rough, recycled bottom layer, commonly used for packaging and cartons where durability and cost-effectiveness are required. Both materials vary in thickness, surface texture, and printing capabilities, influencing their application in different packaging and printing industries.

Composition and Manufacturing Process

Ivory board is composed of multiple layers of wood pulp with a coated, smooth surface achieved through a calendering process, offering high stiffness and whiteness ideal for packaging and printing. Duplex board consists of two layers, typically an uncoated gray back and a coated white front, produced by combining recycled and virgin fibers through a wet pressing technique that balances cost-efficiency and print quality. Manufacturing of ivory board emphasizes uniform fiber distribution and surface treatment for durability, while duplex board manufacturing prioritizes layering methods to enhance rigidity and printability with cost-effective recycled materials.

Key Physical Properties Comparison

Ivory board exhibits a smooth, glossy surface with superior stiffness and a higher density of around 700-800 kg/m3 compared to duplex board's 600-700 kg/m3, making it more durable for premium packaging. Duplex board typically features a coated top layer and an uncoated reverse side, offering moderate rigidity and good printability due to its dual-layer construction. The thickness range for ivory board usually falls between 200-400 microns, whereas duplex board generally measures 150-350 microns, affecting their respective applications in packaging and printing industries.

Surface Finish and Printability

Ivory Board features a smooth, coated surface that enhances print clarity and color vibrancy, making it ideal for high-quality printing applications. Duplex Board has a matte, textured surface that offers a more natural finish but can result in less sharp print detail and subdued colors. The superior surface finish of Ivory Board provides better ink absorption and crisp image reproduction compared to the relatively coarse duplex board.

Applications in Packaging and Printing

Ivory board offers a smooth, glossy surface ideal for high-quality printing and luxury packaging, making it suitable for premium product boxes and retail displays. Duplex board, with its cost-effective structure of a white top layer and a grey back, excels in packaging applications that prioritize strength and durability, such as food containers and corrugated boxes. Both boards serve distinct roles in packaging and printing, with ivory board favored for visual appeal and duplex board valued for functional performance.

Strength and Durability Factors

Ivory Board exhibits superior strength and durability compared to Duplex Board due to its higher GSM (grams per square meter) and multi-layered construction, making it ideal for premium packaging and sturdy printing applications. Duplex Board, while cost-effective and lightweight, typically features a bleached white top layer with a gray back, resulting in less resistance to bending and moisture exposure. For long-term durability and enhanced structural integrity, Ivory Board remains the preferred choice in industries requiring robust and reliable material performance.

Cost Differences and Market Pricing

Ivory board generally commands a higher market price due to its superior surface finish and durability compared to duplex board, which is more economical and widely used for packaging. Cost differences stem from the manufacturing processes where ivory board involves additional coating steps, increasing production expenses, while duplex board consists of two layers of paperboard with a simpler structure. In pricing, manufacturers often leverage these distinctions, with ivory board targeting premium products and duplex board appealing to cost-sensitive applications.

Environmental Impact and Sustainability

Ivory board and duplex board differ significantly in environmental impact and sustainability, with ivory board typically produced using virgin fibers resulting in higher deforestation rates, while duplex board often incorporates recycled fibers reducing resource depletion. The manufacturing process of duplex board consumes less energy and water, contributing to a lower carbon footprint compared to ivory board production. Choosing duplex board supports sustainable forestry practices and promotes circular economy principles by enabling easier recycling and waste reduction.

Choosing the Right Board for Your Project

Ivory Board offers a smooth, bright surface ideal for premium packaging and high-quality printing projects, while Duplex Board provides a sturdy, cost-effective solution with a white front and brown back suited for cartons and food packaging. Consider the project's aesthetic needs, durability requirements, and budget constraints when selecting between Ivory and Duplex boards to ensure optimal performance and visual appeal. Evaluating factors like print quality, moisture resistance, and structural strength helps determine the best board choice for professional and commercial paper applications.

Conclusion: Which is Better—Ivory Board or Duplex Board?

Ivory board offers a premium, smooth finish ideal for high-end packaging and printing, while duplex board provides a cost-effective, sturdy option suited for general packaging needs. The choice depends on the application; ivory board excels in presentation and durability, whereas duplex board is preferred for economical bulk packaging. Industries prioritizing aesthetics and rigidity benefit more from ivory board, whereas those focusing on functionality and budget typically select duplex board.

Ivory Board vs Duplex Board Infographic

materialdif.com

materialdif.com