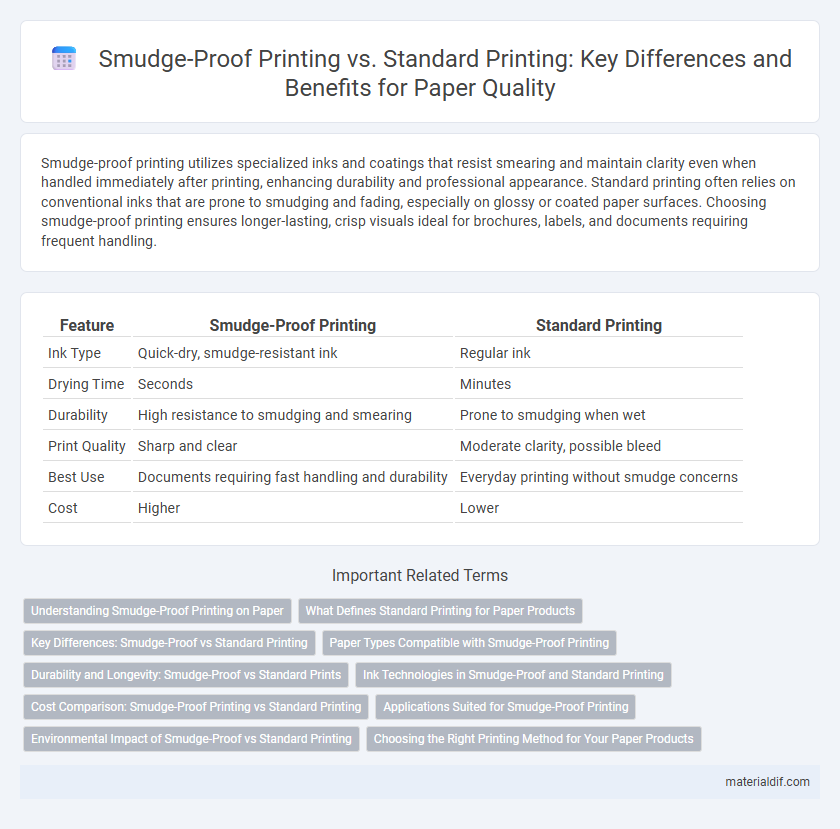

Smudge-proof printing utilizes specialized inks and coatings that resist smearing and maintain clarity even when handled immediately after printing, enhancing durability and professional appearance. Standard printing often relies on conventional inks that are prone to smudging and fading, especially on glossy or coated paper surfaces. Choosing smudge-proof printing ensures longer-lasting, crisp visuals ideal for brochures, labels, and documents requiring frequent handling.

Table of Comparison

| Feature | Smudge-Proof Printing | Standard Printing |

|---|---|---|

| Ink Type | Quick-dry, smudge-resistant ink | Regular ink |

| Drying Time | Seconds | Minutes |

| Durability | High resistance to smudging and smearing | Prone to smudging when wet |

| Print Quality | Sharp and clear | Moderate clarity, possible bleed |

| Best Use | Documents requiring fast handling and durability | Everyday printing without smudge concerns |

| Cost | Higher | Lower |

Understanding Smudge-Proof Printing on Paper

Smudge-proof printing on paper utilizes specialized ink formulations and drying techniques that significantly reduce ink smearing, ensuring crisp and clean text or images even after handling. This method often involves quick-dry inks combined with coated paper surfaces designed to absorb ink rapidly without bleed-through, enhancing print durability and legibility. Compared to standard printing, smudge-proof printing is ideal for high-quality documents, labels, and images requiring long-lasting clarity in various environmental conditions.

What Defines Standard Printing for Paper Products

Standard printing for paper products typically involves the use of traditional ink formulations that dry on the surface but remain prone to smudging when exposed to moisture or friction. This conventional method relies on solvent- or water-based inks that absorb into the fibers, offering cost-effective and widely compatible printing but limited durability. The defining characteristic of standard printing lies in its basic ink adhesion properties without specialized coatings or treatments to resist smearing or fingerprint marks.

Key Differences: Smudge-Proof vs Standard Printing

Smudge-proof printing uses specially formulated ink or toner that resists smearing and drying quickly, making it ideal for documents handled frequently or exposed to moisture. Standard printing relies on conventional inks that may remain wet longer and are more susceptible to smudging, especially on glossy or coated paper types. This key difference impacts print quality, durability, and usability across various printing needs and environments.

Paper Types Compatible with Smudge-Proof Printing

Smudge-proof printing is most effective on coated papers such as glossy, semi-gloss, and matte finishes, which have a sealed surface designed to prevent ink absorption and smearing. Plain uncoated paper, commonly used in standard printing, is less compatible because its porous texture allows inks to spread and smudge easily. Specialty papers treated specifically for laser or inkjet smudge resistance provide enhanced durability, making them ideal for high-quality, smudge-proof print applications.

Durability and Longevity: Smudge-Proof vs Standard Prints

Smudge-proof printing uses specialized inks and coating technologies that enhance durability by resisting smears, moisture, and wear, ensuring longevity even under frequent handling. Standard printing, while cost-effective, often lacks resistance to smudging and fading, leading to quicker degradation and less vibrant prints over time. Investing in smudge-proof prints ensures a longer lifespan and sustained quality, particularly for documents and materials requiring frequent use or display.

Ink Technologies in Smudge-Proof and Standard Printing

Smudge-proof printing utilizes advanced ink technologies such as UV-curable and gel-based inks, which dry rapidly and resist smearing on various paper surfaces. Standard printing typically relies on water-based or solvent inks that absorb into paper fibers but remain vulnerable to smudging, especially on glossy or coated papers. The chemical composition and drying mechanisms of smudge-proof inks ensure sharper, more durable print quality, enhancing text and image longevity.

Cost Comparison: Smudge-Proof Printing vs Standard Printing

Smudge-proof printing generally incurs higher initial costs due to specialized inks and materials designed to resist smearing, whereas standard printing uses more affordable, conventional inks. Over time, smudge-proof prints reduce reprints and waste by minimizing errors caused by smudges, potentially lowering overall operational costs. Businesses weighing cost efficiency should consider print volume and quality needs, as smudge-proof printing offers long-term savings despite its upfront expense.

Applications Suited for Smudge-Proof Printing

Smudge-proof printing is ideal for applications requiring high durability and clarity, such as labels on packaging, outdoor signage, and product tags exposed to moisture or frequent handling. Its resistance to smearing ensures that barcodes, QR codes, and text remain legible throughout the product lifecycle, enhancing scan accuracy and customer experience. Industries like pharmaceuticals, cosmetics, and food packaging benefit significantly from smudge-proof printing to maintain compliance and brand integrity.

Environmental Impact of Smudge-Proof vs Standard Printing

Smudge-proof printing significantly reduces paper waste by minimizing the need for reprints due to smudges, thereby conserving resources and lowering environmental impact compared to standard printing. Standard printing often involves the use of chemical inks that can contain volatile organic compounds (VOCs), while smudge-proof technology utilizes eco-friendly formulations that reduce harmful emissions. Energy consumption during the drying process is also lower in smudge-proof printing, contributing to a smaller carbon footprint overall.

Choosing the Right Printing Method for Your Paper Products

Smudge-proof printing uses specialized ink formulations and coatings to ensure sharp, clean images that resist smearing on paper products, ideal for marketing materials and packaging requiring durability. Standard printing methods, such as offset or digital printing, offer cost-effective solutions but may be prone to smudging when handled frequently or exposed to moisture. Selecting the right printing method depends on the paper type, intended use, and desired print longevity to optimize both aesthetic appeal and functionality.

Smudge-Proof Printing vs Standard Printing Infographic

materialdif.com

materialdif.com