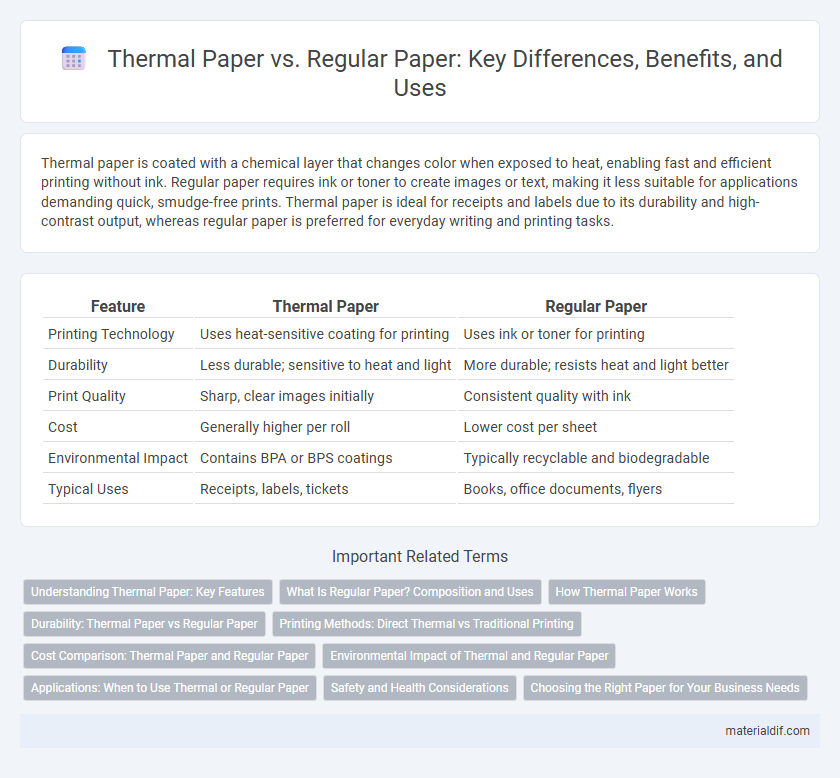

Thermal paper is coated with a chemical layer that changes color when exposed to heat, enabling fast and efficient printing without ink. Regular paper requires ink or toner to create images or text, making it less suitable for applications demanding quick, smudge-free prints. Thermal paper is ideal for receipts and labels due to its durability and high-contrast output, whereas regular paper is preferred for everyday writing and printing tasks.

Table of Comparison

| Feature | Thermal Paper | Regular Paper |

|---|---|---|

| Printing Technology | Uses heat-sensitive coating for printing | Uses ink or toner for printing |

| Durability | Less durable; sensitive to heat and light | More durable; resists heat and light better |

| Print Quality | Sharp, clear images initially | Consistent quality with ink |

| Cost | Generally higher per roll | Lower cost per sheet |

| Environmental Impact | Contains BPA or BPS coatings | Typically recyclable and biodegradable |

| Typical Uses | Receipts, labels, tickets | Books, office documents, flyers |

Understanding Thermal Paper: Key Features

Thermal paper is specially coated to react to heat, allowing images and text to appear without ink, unlike regular paper which requires toner or ink. This heat-sensitive coating provides quick, high-resolution printouts ideal for receipts, labels, and tickets. Understanding these key features highlights thermal paper's efficiency in environments where fast, clean printing is essential.

What Is Regular Paper? Composition and Uses

Regular paper, typically made from wood pulp through mechanical and chemical processes, consists mainly of cellulose fibers that provide durability and flexibility. This versatile material is used extensively in printing, writing, packaging, and publishing due to its ability to absorb ink and maintain structural integrity. Unlike thermal paper, regular paper requires traditional ink-based printing methods and supports a wider range of applications from office documents to artistic prints.

How Thermal Paper Works

Thermal paper is coated with a special heat-sensitive layer containing dye and developer chemicals that react when exposed to heat, producing an image without the need for ink. When the thermal print head heats specific areas of the paper, a chemical reaction occurs, causing the coating to change color and create text or images. This process enables fast, quiet printing ideal for receipts, labels, and tickets, differentiating it from regular paper that requires ink or toner for printing.

Durability: Thermal Paper vs Regular Paper

Thermal paper features a heat-sensitive coating that can fade over time, especially when exposed to heat, light, or oils, resulting in reduced durability compared to regular paper. Regular paper, typically made from wood pulp without heat-sensitive layers, maintains print clarity longer under various environmental conditions. For applications requiring long-term document preservation, regular paper is generally more reliable due to its resistance to fading and physical wear.

Printing Methods: Direct Thermal vs Traditional Printing

Thermal paper uses heat-sensitive coating that reacts directly to the print head's heat, enabling direct thermal printing without ink or toner, ideal for receipts and labels requiring fast, smudge-free output. Regular paper relies on traditional printing methods such as inkjet or laser printing, which use ink or toner to form images and text, offering high-quality, durable prints suitable for documents and photographs. Direct thermal printing on thermal paper tends to be more cost-effective and faster but less durable over time compared to traditional printing on regular paper, which provides longevity and resistance to fading.

Cost Comparison: Thermal Paper and Regular Paper

Thermal paper generally incurs higher upfront costs compared to regular paper due to its specialized heat-sensitive coating, but it eliminates the need for ink or toner, reducing ongoing expenses. Regular paper is more affordable per sheet yet requires compatible printers and consumables, increasing total operational costs over time. Businesses must weigh thermal paper's increased material cost against savings in printing supplies when assessing overall economic efficiency.

Environmental Impact of Thermal and Regular Paper

Thermal paper production uses chemical coatings that can release bisphenol A (BPA) or bisphenol S (BPS), posing potential environmental and health hazards during manufacturing and disposal. Regular paper typically undergoes bleaching and chemical treatments, resulting in higher water consumption and energy use, contributing to greater greenhouse gas emissions compared to thermal paper. Recycling regular paper is more efficient and environmentally friendly, whereas thermal paper often cannot be recycled due to its chemical coatings, increasing landfill waste.

Applications: When to Use Thermal or Regular Paper

Thermal paper is ideal for point-of-sale receipts, shipping labels, and ticket printing due to its heat-sensitive coating that produces fast, clear images without ink. Regular paper suits applications requiring durability, archival quality, or extensive writing and printing with ink, such as legal documents, reports, and office printing. Choosing between thermal and regular paper depends on requirements for print speed, image longevity, and resistance to fading or abrasion.

Safety and Health Considerations

Thermal paper contains BPA or BPS chemicals that can transfer to skin, raising concerns about hormonal disruption and long-term health risks. Regular paper, often free from these coatings, poses fewer chemical exposure risks but may involve other additives like bleach or ink that also affect safety. Handling thermal paper with care and limiting direct contact reduces potential health hazards compared to untreated paper products.

Choosing the Right Paper for Your Business Needs

Thermal paper offers faster, noiseless printing and is ideal for point-of-sale systems, receipts, and labels requiring immediate drying and smudge resistance. Regular paper provides versatility for high-quality color printing, documents, and marketing materials, making it suitable for broader office and professional uses. Assessing your business needs, such as print volume, durability, and cost efficiency, helps determine whether thermal or regular paper best supports your operational goals.

Thermal Paper vs Regular Paper Infographic

materialdif.com

materialdif.com