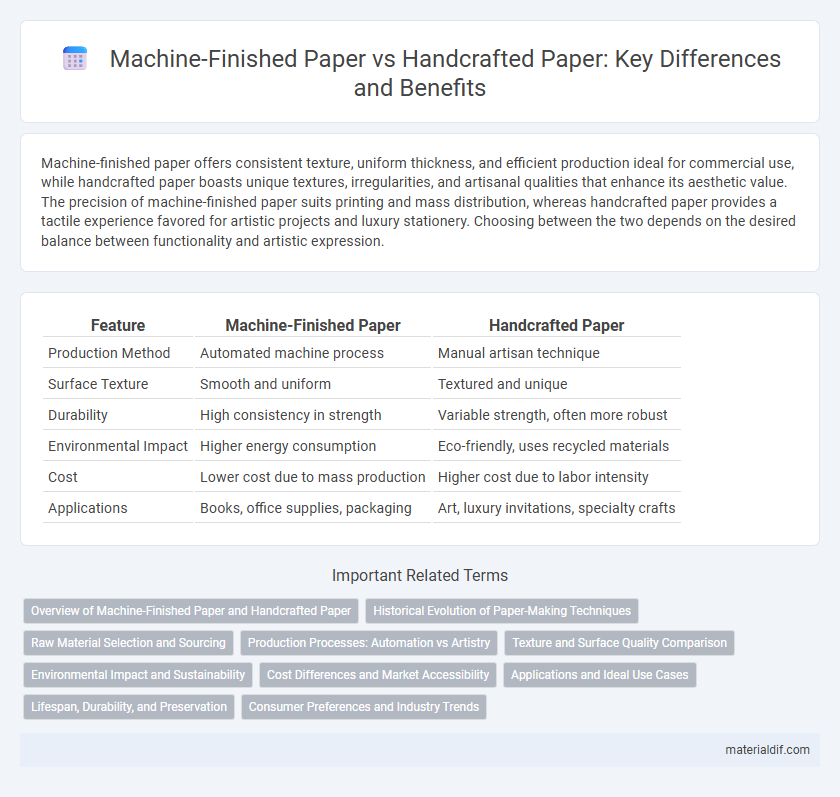

Machine-finished paper offers consistent texture, uniform thickness, and efficient production ideal for commercial use, while handcrafted paper boasts unique textures, irregularities, and artisanal qualities that enhance its aesthetic value. The precision of machine-finished paper suits printing and mass distribution, whereas handcrafted paper provides a tactile experience favored for artistic projects and luxury stationery. Choosing between the two depends on the desired balance between functionality and artistic expression.

Table of Comparison

| Feature | Machine-Finished Paper | Handcrafted Paper |

|---|---|---|

| Production Method | Automated machine process | Manual artisan technique |

| Surface Texture | Smooth and uniform | Textured and unique |

| Durability | High consistency in strength | Variable strength, often more robust |

| Environmental Impact | Higher energy consumption | Eco-friendly, uses recycled materials |

| Cost | Lower cost due to mass production | Higher cost due to labor intensity |

| Applications | Books, office supplies, packaging | Art, luxury invitations, specialty crafts |

Overview of Machine-Finished Paper and Handcrafted Paper

Machine-finished paper is produced using automated processes that ensure uniform texture, consistent thickness, and mass production capability, ideal for commercial printing and packaging. Handcrafted paper involves traditional techniques where fibers are manually processed and formed, resulting in unique textures, natural imperfections, and higher artistic value. The choice between machine-finished and handcrafted paper depends on the desired quality, purpose, and cost considerations.

Historical Evolution of Paper-Making Techniques

Machine-finished paper revolutionized the paper industry by introducing industrial-scale production methods in the 19th century, utilizing continuous paper machines like the Fourdrinier to produce uniform sheets rapidly. In contrast, handcrafted paper, rooted in ancient techniques dating back to China around 100 BCE, involved manual processes such as vat dipping and pressing, resulting in unique textures and fiber patterns. The historical evolution reflects a shift from labor-intensive artisanal craftsmanship to mechanized efficiency, impacting paper quality, availability, and cost.

Raw Material Selection and Sourcing

Machine-finished paper typically utilizes wood pulp sourced from fast-growing, commercially cultivated trees to ensure consistency and cost-efficiency, while handcrafted paper often relies on diverse, natural fibers such as cotton, hemp, or recycled materials, selected for their texture and durability. The raw material selection in handcrafted paper emphasizes sustainability and unique fiber composition, often procured from local or artisanal suppliers, contrasting with the industrial supply chains of machine-finished paper. This distinction in sourcing directly impacts the paper's quality, environmental footprint, and tactile characteristics.

Production Processes: Automation vs Artistry

Machine-finished paper relies on automated processes including high-speed paper machines, precise rollers, and chemical treatments to achieve uniform texture and consistent quality. Handcrafted paper production involves manual techniques such as sheet forming with moulds, natural fiber blending, and traditional drying methods, emphasizing craftsmanship and unique texture. These contrasting methods highlight the efficiency of automation versus the artistic value inherent in handmade paper.

Texture and Surface Quality Comparison

Machine-finished paper exhibits a uniform texture with a smooth surface ideal for high-speed printing and consistent ink absorption, while handcrafted paper offers a unique, tactile texture characterized by natural irregularities and a rougher surface that enhances aesthetic appeal. The surface quality of machine-finished paper is controlled by automated calendaring and pressing processes, resulting in minimal surface defects and high brightness, whereas handcrafted paper's surface varies due to manual sheet formation and drying techniques, providing a distinctive handmade character. Differences in fiber distribution and pressing intensity impact the durability and feel of each type, with machine-finished paper prioritizing efficiency and consistency, and handcrafted paper emphasizing artisanal texture and surface uniqueness.

Environmental Impact and Sustainability

Machine-finished paper typically involves large-scale industrial processes that consume significant amounts of water, energy, and chemicals, contributing to higher carbon emissions and pollution levels. Handcrafted paper, by contrast, uses manual techniques with natural fibers and minimal processing, resulting in a lower environmental footprint and greater biodegradability. Emphasizing sustainable sourcing and reduced resource consumption, handcrafted paper supports eco-friendly practices and promotes conservation of natural resources.

Cost Differences and Market Accessibility

Machine-finished paper offers significantly lower production costs due to automated processes, enabling mass production and competitive pricing in large-scale markets. Handcrafted paper involves labor-intensive techniques, resulting in higher costs and limited availability primarily in niche markets targeting artisanal and luxury segments. Market accessibility favors machine-finished paper through widespread distribution channels, whereas handcrafted paper relies on specialized vendors and boutique retailers.

Applications and Ideal Use Cases

Machine-finished paper offers consistent texture and uniform thickness, making it ideal for mass printing, packaging, and commercial publishing where efficiency and standardization are crucial. Handcrafted paper, valued for its unique texture and organic appearance, suits artisanal stationery, luxury invitations, and fine art printing that require a distinct, personalized touch. Both paper types serve specific niches: machine-finished paper supports large-scale production, while handcrafted paper enhances creative and premium projects.

Lifespan, Durability, and Preservation

Machine-finished paper typically offers greater durability and longer lifespan due to its uniform fibers and chemical treatments that resist aging and environmental damage. Handcrafted paper, while often more aesthetically unique and artisanal, tends to be more fragile and susceptible to deterioration over time without specialized preservation methods. Proper archival techniques can extend the lifespan of both types, but machine-finished paper remains the preferred choice for long-term preservation in libraries and museums.

Consumer Preferences and Industry Trends

Machine-finished paper dominates the market due to its consistent quality, cost-effectiveness, and large-scale production, appealing to consumers prioritizing affordability and uniformity. Handcrafted paper attracts niche consumers seeking unique textures, eco-friendly materials, and artisanal value, driving growth in luxury, gift, and specialty stationery segments. Industry trends indicate increasing demand for sustainable handcrafted paper amid rising environmental awareness, while machine-finished paper maintains strength in mass-market applications.

Machine-Finished Paper vs Handcrafted Paper Infographic

materialdif.com

materialdif.com