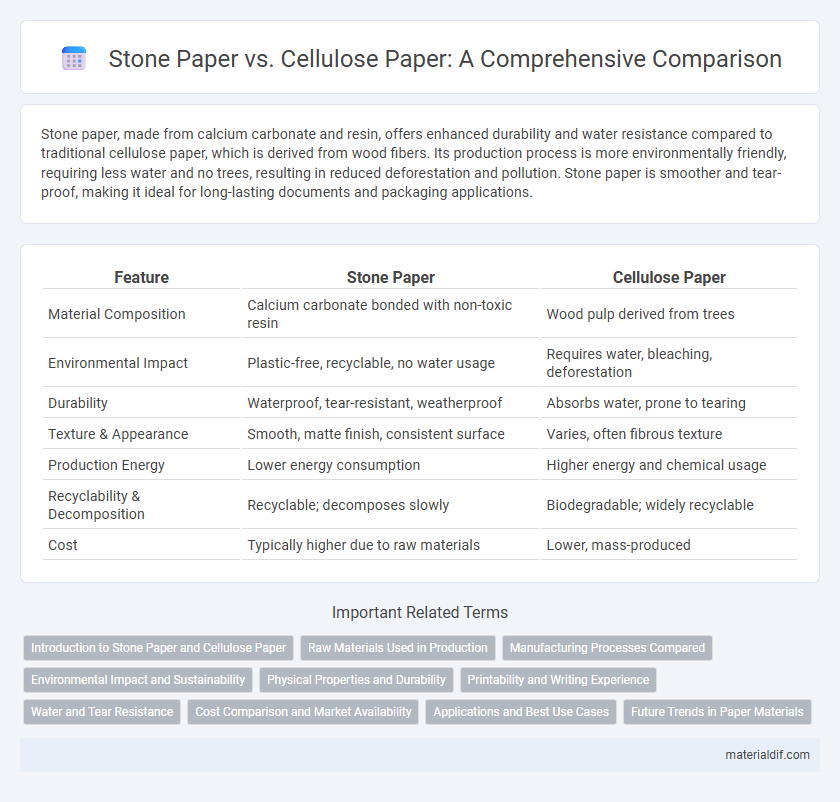

Stone paper, made from calcium carbonate and resin, offers enhanced durability and water resistance compared to traditional cellulose paper, which is derived from wood fibers. Its production process is more environmentally friendly, requiring less water and no trees, resulting in reduced deforestation and pollution. Stone paper is smoother and tear-proof, making it ideal for long-lasting documents and packaging applications.

Table of Comparison

| Feature | Stone Paper | Cellulose Paper |

|---|---|---|

| Material Composition | Calcium carbonate bonded with non-toxic resin | Wood pulp derived from trees |

| Environmental Impact | Plastic-free, recyclable, no water usage | Requires water, bleaching, deforestation |

| Durability | Waterproof, tear-resistant, weatherproof | Absorbs water, prone to tearing |

| Texture & Appearance | Smooth, matte finish, consistent surface | Varies, often fibrous texture |

| Production Energy | Lower energy consumption | Higher energy and chemical usage |

| Recyclability & Decomposition | Recyclable; decomposes slowly | Biodegradable; widely recyclable |

| Cost | Typically higher due to raw materials | Lower, mass-produced |

Introduction to Stone Paper and Cellulose Paper

Stone paper, made from calcium carbonate bound with high-density polyethylene, offers a waterproof, durable, and tear-resistant alternative to traditional cellulose paper, which is produced from wood pulp fibers. Cellulose paper's biodegradable composition and versatility have made it the dominant material globally, but stone paper's eco-friendly manufacturing process, which uses no water or bleach, presents an innovative solution to reduce deforestation and chemical waste. Both materials serve diverse applications, yet stone paper stands out for its resistance to moisture and chemicals, while cellulose paper remains favored for its recyclability and widespread availability.

Raw Materials Used in Production

Stone paper is primarily made from calcium carbonate combined with a small amount of non-toxic resin, eliminating the need for wood pulp or water in its production. Cellulose paper relies on wood fibers extracted from trees, requiring significant water and chemical treatments to process lignin and hemicellulose. The raw materials for stone paper offer a more sustainable alternative by reducing deforestation and water consumption compared to traditional cellulose-based paper manufacturing.

Manufacturing Processes Compared

Stone paper manufacturing involves using calcium carbonate bonded with high-density polyethylene through a mechanical process requiring less water and no bleaching chemicals, resulting in a more environmentally friendly product. In contrast, cellulose paper production relies on wood pulp subjected to energy-intensive pulping, bleaching, and chemical treatments that consume significant water and generate waste. The stone paper process reduces carbon emissions and deforestation impacts, making it a sustainable alternative to traditional cellulose paper manufacturing.

Environmental Impact and Sustainability

Stone paper, made from calcium carbonate and resin, significantly reduces deforestation and water usage compared to traditional cellulose paper derived from wood pulp. Its production emits fewer greenhouse gases and produces minimal waste, making it a sustainable alternative with a lower environmental footprint. However, recycling processes for stone paper differ and require specialized facilities, whereas cellulose paper benefits from well-established, widely available recycling systems.

Physical Properties and Durability

Stone paper, made from calcium carbonate bonded with resin, offers superior water resistance and tear strength compared to traditional cellulose paper derived from wood pulp. Its non-porous surface prevents ink bleed and enhances durability under humid conditions, while cellulose paper tends to absorb moisture and degrade faster. This makes stone paper more suitable for applications requiring long-lasting and robust material performance.

Printability and Writing Experience

Stone paper offers superior printability with its smooth, non-porous surface that enhances ink adhesion, resulting in vibrant colors and sharp details. Unlike cellulose paper, it resists ink bleeding and smudging, providing a cleaner and more durable print. Writing on stone paper feels smooth and consistent, though it may require specific pens for optimal ink drying, while cellulose paper offers a more traditional tactile feedback favored for handwriting.

Water and Tear Resistance

Stone paper exhibits superior water resistance compared to cellulose paper due to its non-porous, hydrophobic structure, making it less likely to absorb moisture and degrade. Its durability is enhanced by higher tear resistance, attributed to the dense mineral content of calcium carbonate bonded with a resin, compared to the fibrous composition of cellulose paper. These properties make stone paper ideal for applications requiring durability in wet or rough handling conditions.

Cost Comparison and Market Availability

Stone paper generally incurs higher production costs due to the use of calcium carbonate and HDPE binders, making it more expensive than traditional cellulose paper derived from wood pulp. Despite its environmental advantages and durability, stone paper's market availability remains limited to niche sectors and specialty products, whereas cellulose paper enjoys widespread distribution and diverse applications across global markets. The cost differential and established supply chains contribute significantly to cellulose paper's dominant market presence over stone paper.

Applications and Best Use Cases

Stone paper offers exceptional water resistance and durability, making it ideal for outdoor maps, waterproof notebooks, and packaging materials exposed to moisture. Cellulose paper excels in print quality and biodegradability, suited for books, magazines, office paper, and eco-friendly packaging. Choosing between stone paper and cellulose paper depends on specific application needs such as durability, environmental impact, and aesthetic properties.

Future Trends in Paper Materials

Stone paper, made from calcium carbonate bonded with resin, offers a sustainable alternative to traditional cellulose paper by reducing deforestation and water consumption. Advancements in biodegradable resins and enhanced durability position stone paper as a leading candidate for eco-friendly packaging and specialty printing industries. Emerging research on hybrid materials integrating stone and cellulose fibers aims to optimize environmental impact and mechanical performance for future paper applications.

Stone Paper vs Cellulose Paper Infographic

materialdif.com

materialdif.com