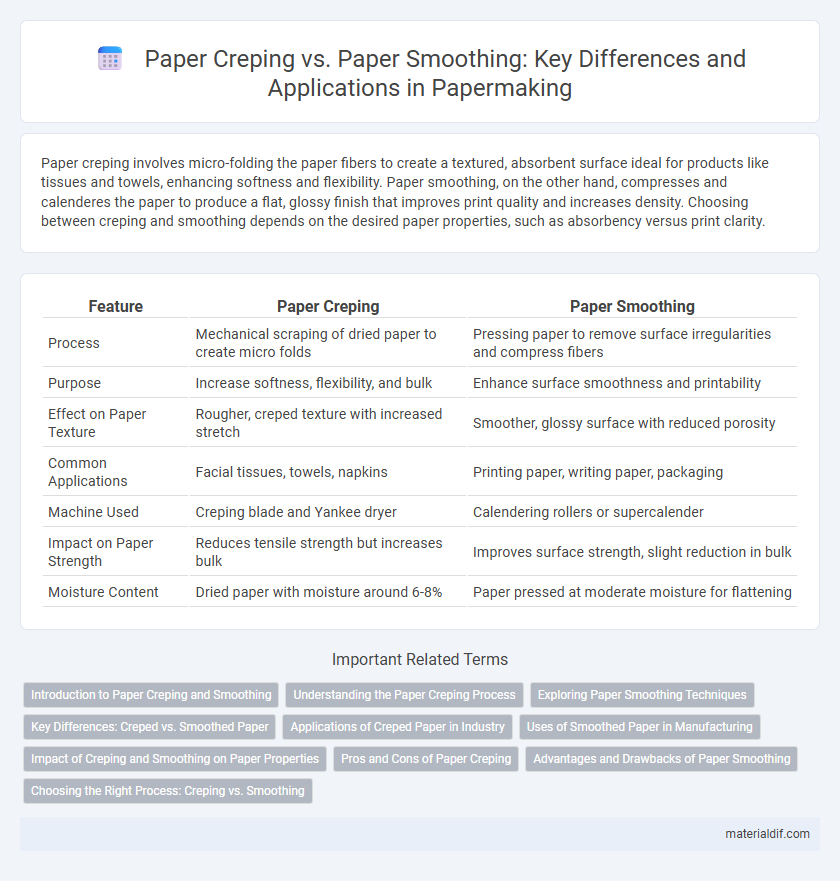

Paper creping involves micro-folding the paper fibers to create a textured, absorbent surface ideal for products like tissues and towels, enhancing softness and flexibility. Paper smoothing, on the other hand, compresses and calenderes the paper to produce a flat, glossy finish that improves print quality and increases density. Choosing between creping and smoothing depends on the desired paper properties, such as absorbency versus print clarity.

Table of Comparison

| Feature | Paper Creping | Paper Smoothing |

|---|---|---|

| Process | Mechanical scraping of dried paper to create micro folds | Pressing paper to remove surface irregularities and compress fibers |

| Purpose | Increase softness, flexibility, and bulk | Enhance surface smoothness and printability |

| Effect on Paper Texture | Rougher, creped texture with increased stretch | Smoother, glossy surface with reduced porosity |

| Common Applications | Facial tissues, towels, napkins | Printing paper, writing paper, packaging |

| Machine Used | Creping blade and Yankee dryer | Calendering rollers or supercalender |

| Impact on Paper Strength | Reduces tensile strength but increases bulk | Improves surface strength, slight reduction in bulk |

| Moisture Content | Dried paper with moisture around 6-8% | Paper pressed at moderate moisture for flattening |

Introduction to Paper Creping and Smoothing

Paper creping creates a textured surface by gently scraping the paper web off the dryer surface, enhancing softness, stretch, and bulk, ideal for tissue products. Paper smoothing involves compressing the paper to reduce surface roughness, improve gloss, and increase density, commonly used for printing and writing papers. Understanding the balance between creping and smoothing processes is essential for optimizing paper performance to meet specific applications.

Understanding the Paper Creping Process

Paper creping involves micro-folds created by scraping the paper off a drying cylinder with a doctor blade, enhancing flexibility and softness for applications like tissue and towel products. Smoothing, in contrast, compresses the paper fibers to produce a flat, uniform surface with less elasticity, suited for printing and writing papers. Understanding the creping process is crucial for controlling paper thickness, bulk, and tensile properties, directly impacting product performance and consumer experience.

Exploring Paper Smoothing Techniques

Paper smoothing involves processes such as calendering and surface sizing to enhance paper uniformity, gloss, and printability by reducing roughness. Using mechanical or chemical treatments, smoothing techniques minimize fiber protrusions and improve surface density, resulting in improved tactile feel and ink receptivity. Advanced methods include supercalendering and surface coating, which optimize paper for high-quality printing and durability.

Key Differences: Creped vs. Smoothed Paper

Creped paper features a textured surface created by a controlled wrinkling process that enhances softness and absorbency, making it ideal for tissues and towels. In contrast, smoothed paper undergoes calendaring or pressing to create a sleek, flat finish, improving print clarity and durability for applications like office paper and packaging. The key difference lies in surface texture and functional use: creping increases flexibility and bulk, while smoothing prioritizes strength and visual uniformity.

Applications of Creped Paper in Industry

Creped paper features a crinkled texture that enhances flexibility and absorbency, making it ideal for industrial applications such as tissue manufacturing, packaging, and wiping products. Its increased surface area improves softness and elasticity, which are critical in hygiene products like facial tissues, paper towels, and diapers. The creping process also boosts bulk and porosity, allowing for better ink absorption in printing and superior cushioning in packaging materials.

Uses of Smoothed Paper in Manufacturing

Smoothed paper is widely used in packaging manufacturing due to its uniform surface, which enhances print quality and improves the adhesion of coatings and adhesives. In the production of labels and flexible packaging, the smooth texture ensures consistent ink absorption, resulting in sharper graphics and vibrant colors. Furthermore, smoothed paper's reduced surface roughness contributes to better mechanical properties, making it ideal for folding, gluing, and laminating processes.

Impact of Creping and Smoothing on Paper Properties

Creping significantly enhances paper flexibility and softness by introducing microfolds that increase bulk and porosity, while smoothing reduces surface roughness to improve gloss and printability. The creping process compromises tensile strength due to fiber disruption, whereas smoothing boosts fiber bonding, resulting in higher strength and dimensional stability. These opposing modifications directly influence paper applications, with creped paper favored for tissue products requiring absorbency and softness, and smoothed paper preferred for high-quality printing and packaging.

Pros and Cons of Paper Creping

Paper creping enhances flexibility and softness by creating micro-folds on the paper surface, improving absorbency and printability. Downsides include reduced tensile strength and increased surface roughness, which can affect smoothness and durability. This process is essential for tissue production but may compromise paper brightness and uniformity compared to smoothing techniques.

Advantages and Drawbacks of Paper Smoothing

Paper smoothing enhances surface uniformity, improving print quality and readability by reducing roughness and ink absorption inconsistencies. However, excessive smoothing can diminish paper bulk and opacity, leading to decreased tactile thickness and potential transparency issues. Balancing smoothing levels is crucial to maintain both aesthetic appeal and functional durability in printed materials.

Choosing the Right Process: Creping vs. Smoothing

Paper creping involves micro-folds that increase bulk and softness, ideal for tissue and towel products requiring absorbency and texture. Paper smoothing enhances surface uniformity and gloss, making it suitable for printing papers and packaging materials demanding a sleek finish. Choosing between creping and smoothing depends on the end-use requirements for texture, strength, and visual appeal.

Paper creping vs Paper smoothing Infographic

materialdif.com

materialdif.com