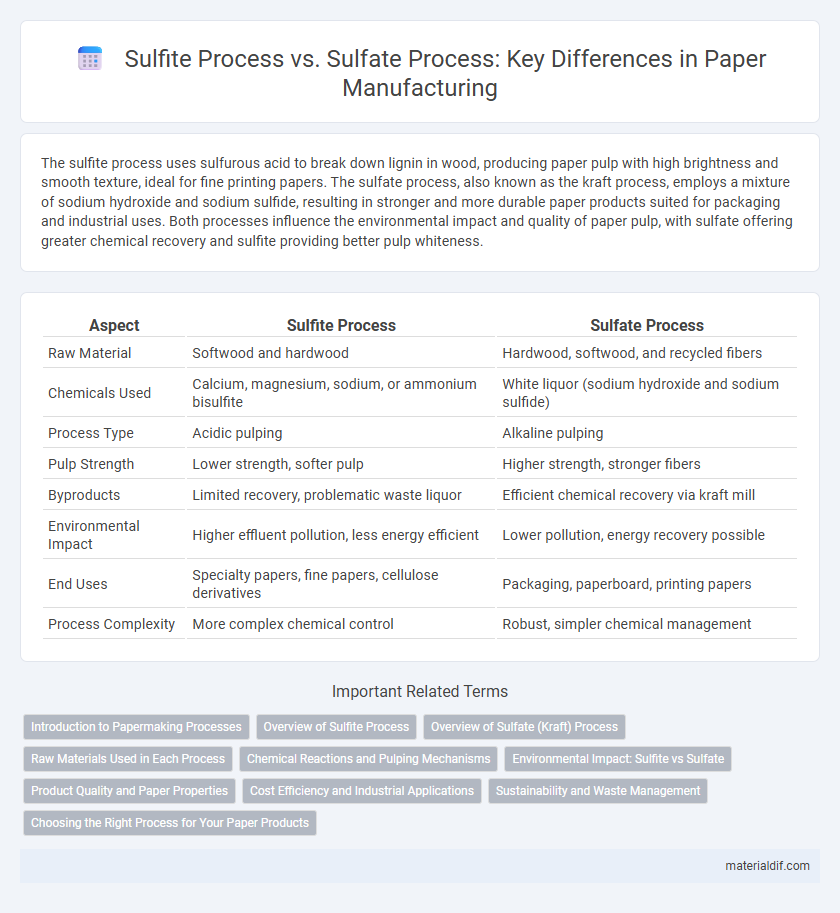

The sulfite process uses sulfurous acid to break down lignin in wood, producing paper pulp with high brightness and smooth texture, ideal for fine printing papers. The sulfate process, also known as the kraft process, employs a mixture of sodium hydroxide and sodium sulfide, resulting in stronger and more durable paper products suited for packaging and industrial uses. Both processes influence the environmental impact and quality of paper pulp, with sulfate offering greater chemical recovery and sulfite providing better pulp whiteness.

Table of Comparison

| Aspect | Sulfite Process | Sulfate Process |

|---|---|---|

| Raw Material | Softwood and hardwood | Hardwood, softwood, and recycled fibers |

| Chemicals Used | Calcium, magnesium, sodium, or ammonium bisulfite | White liquor (sodium hydroxide and sodium sulfide) |

| Process Type | Acidic pulping | Alkaline pulping |

| Pulp Strength | Lower strength, softer pulp | Higher strength, stronger fibers |

| Byproducts | Limited recovery, problematic waste liquor | Efficient chemical recovery via kraft mill |

| Environmental Impact | Higher effluent pollution, less energy efficient | Lower pollution, energy recovery possible |

| End Uses | Specialty papers, fine papers, cellulose derivatives | Packaging, paperboard, printing papers |

| Process Complexity | More complex chemical control | Robust, simpler chemical management |

Introduction to Papermaking Processes

The sulfite process uses sulfurous acid and bisulfite ions to break down lignin, producing softer, brighter pulp ideal for fine paper products. In contrast, the sulfate process, also known as the kraft process, employs a mixture of sodium hydroxide and sodium sulfide, yielding stronger, more durable pulp suited for packaging and heavy-duty papers. Both processes are fundamental in papermaking, influencing fiber quality, environmental impact, and the range of paper products produced worldwide.

Overview of Sulfite Process

The sulfite process is a chemical method for producing paper pulp by dissolving lignin in wood chips using sulfurous acid and bisulfite ions, resulting in a softer, more flexible pulp ideal for producing fine paper products. This process typically operates at lower temperatures and produces a pulp with higher brightness and better dye affinity compared to the sulfate process. Sulfite pulping is favored for applications requiring superior printability and smoother paper surfaces, despite lower strength properties than sulfate pulp.

Overview of Sulfate (Kraft) Process

The Sulfate (Kraft) Process is the most widely used chemical pulping method, employing sodium hydroxide and sodium sulfide to break down lignin and separate cellulose fibers from wood chips. This process produces strong, durable pulp with higher yield and better fiber strength compared to the Sulfite Process, making it ideal for producing paper products requiring high tensile strength. The Kraft process also allows for efficient chemical recovery and is more adaptable to a variety of wood species, contributing to its global dominance in pulp production.

Raw Materials Used in Each Process

The sulfite process primarily uses wood chips from softwood species such as spruce and pine as raw materials due to their high cellulose content and favorable reaction with sulfite chemicals. In contrast, the sulfate process, also known as kraft pulping, can efficiently utilize a broader range of raw materials, including both softwood and hardwood species, as well as recycled paper. The ability of the kraft process to digest tougher lignin structures makes it more versatile for various fiber sources compared to the sulfite process.

Chemical Reactions and Pulping Mechanisms

The sulfite process involves the use of sulfurous acid and bisulfite ions to cleave lignin bonds, producing pulp with high brightness and purity, primarily through sulfonation that increases lignin solubility. In contrast, the sulfate (Kraft) process employs sodium hydroxide and sodium sulfide to break down lignin via alkaline hydrolysis and cleavage of ether bonds, resulting in stronger pulp with higher yield but darker color. Both processes rely on the selective removal of lignin and hemicelluloses while preserving cellulose fibers, but their differing chemical reactions influence pulp characteristics and downstream applications.

Environmental Impact: Sulfite vs Sulfate

The sulfite process generates less acidic wastewater but produces higher biochemical oxygen demand (BOD) and chemical oxygen demand (COD), leading to increased water pollution compared to the sulfate process. The sulfate process, while producing more acidic effluents, allows for better recovery of chemicals and generates more solid waste, impacting soil and landfill quality. Both processes require effective waste management to mitigate environmental hazards, with the sulfate process generally favored for sustainable pulp production due to lower water toxicity.

Product Quality and Paper Properties

The sulfite process produces pulp with higher brightness and finer fiber structure, resulting in paper with superior printability and smoothness, while the sulfate process yields stronger, more durable fibers suitable for packaging and heavy-duty paper products. Sulfite pulp generally has lower lignin content, enhancing paper whiteness and reducing the need for extensive bleaching, whereas sulfate pulp contains more residual lignin, requiring additional treatment to achieve comparable brightness. The choice between sulfite and sulfate processes significantly influences the final paper's mechanical strength, surface characteristics, and suitability for different end uses.

Cost Efficiency and Industrial Applications

The sulfite process offers lower initial investment costs but is less efficient for high-yield pulp production compared to the sulfate process, which dominates due to its ability to process a wide range of wood types and generate stronger pulp. Industrial applications favor the sulfate process in producing kraft paper and packaging materials because of its superior strength and chemical recovery system, enhancing overall cost efficiency. The sulfite process remains relevant in specialized paper grades requiring lighter pulp, but its higher operational costs limit broader industrial use.

Sustainability and Waste Management

The sulfite process generates more biodegradable waste due to its use of sulfurous acid, enabling easier wastewater treatment compared to the sulfate process, which produces lignin-rich black liquor requiring energy-intensive recovery systems. Sulfate process mills often implement advanced chemical recovery boilers to burn black liquor, recovering chemicals and generating renewable energy, thereby improving sustainability despite higher initial emissions. Waste management in the sulfite process is challenged by sulfonated lignin residues, whereas the sulfate process benefits from established recovery cycles promoting resource efficiency and reduced environmental impact.

Choosing the Right Process for Your Paper Products

The sulfite process produces paper with superior brightness and smoothness, making it ideal for high-quality printing papers and fine writing papers. The sulfate process, also known as kraft, yields stronger and more durable pulp suitable for packaging, cardboard, and heavyweight paper products. Selecting the appropriate pulping method depends on balancing the desired paper strength, brightness, and cost-efficiency to meet specific product requirements.

Sulfite Process vs Sulfate Process Infographic

materialdif.com

materialdif.com