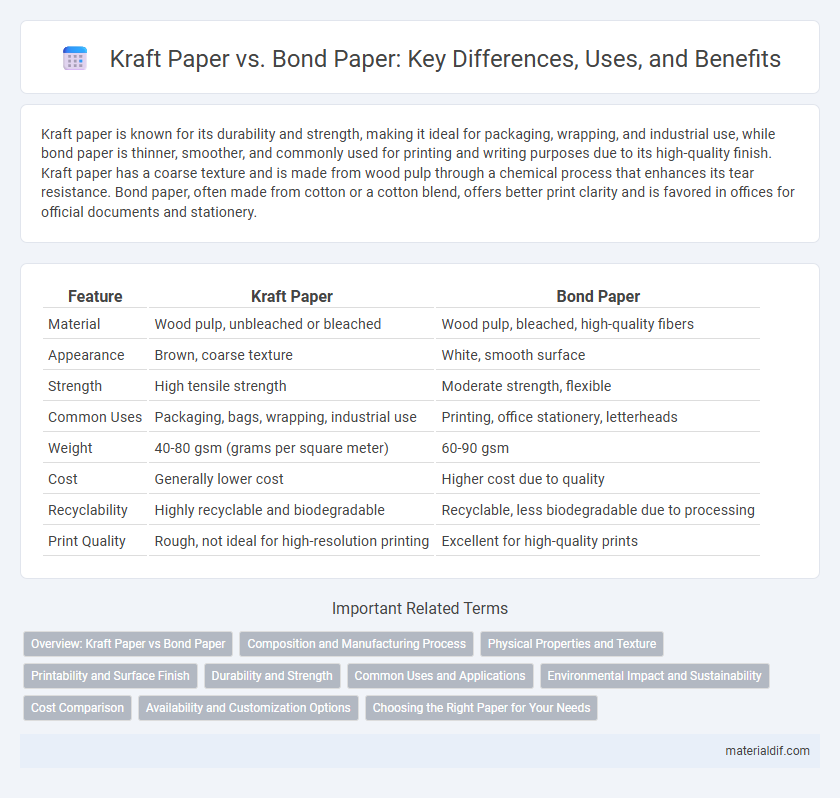

Kraft paper is known for its durability and strength, making it ideal for packaging, wrapping, and industrial use, while bond paper is thinner, smoother, and commonly used for printing and writing purposes due to its high-quality finish. Kraft paper has a coarse texture and is made from wood pulp through a chemical process that enhances its tear resistance. Bond paper, often made from cotton or a cotton blend, offers better print clarity and is favored in offices for official documents and stationery.

Table of Comparison

| Feature | Kraft Paper | Bond Paper |

|---|---|---|

| Material | Wood pulp, unbleached or bleached | Wood pulp, bleached, high-quality fibers |

| Appearance | Brown, coarse texture | White, smooth surface |

| Strength | High tensile strength | Moderate strength, flexible |

| Common Uses | Packaging, bags, wrapping, industrial use | Printing, office stationery, letterheads |

| Weight | 40-80 gsm (grams per square meter) | 60-90 gsm |

| Cost | Generally lower cost | Higher cost due to quality |

| Recyclability | Highly recyclable and biodegradable | Recyclable, less biodegradable due to processing |

| Print Quality | Rough, not ideal for high-resolution printing | Excellent for high-quality prints |

Overview: Kraft Paper vs Bond Paper

Kraft paper is a sturdy, coarse material primarily made from wood pulp using the kraft process, known for its high tear resistance and durability, making it ideal for packaging and industrial uses. Bond paper, characterized by its smooth texture and lightweight quality, is typically produced from high-quality rag pulp and is widely used for printing, stationery, and official documents. The fundamental differences lie in their production methods, texture, strength, and typical applications, with kraft paper excelling in strength and abrasion resistance, while bond paper offers superior printing quality and surface smoothness.

Composition and Manufacturing Process

Kraft paper is produced using the kraft process, which involves chemical pulping of wood chips to remove lignin, resulting in strong, durable fibers primarily composed of cellulose. Bond paper is made from wood pulp through mechanical or chemical pulping methods, typically refined and bleached to achieve a smoother and lighter finish. The kraft process produces a coarser, thicker paper ideal for packaging, while bond paper's manufacturing prioritizes whiteness and strength suitable for writing and printing applications.

Physical Properties and Texture

Kraft paper exhibits a rougher texture and higher tensile strength due to its unbleached wood pulp composition, making it more durable and resistant to tearing compared to bond paper. Bond paper features a smoother surface with a finer grain, created from bleached wood pulp, which allows for better ink absorption and sharper print quality. The denser fibers in bond paper result in a lighter, thinner sheet, while kraft paper tends to be thicker and more rigid, ideal for packaging and heavy-duty applications.

Printability and Surface Finish

Kraft paper offers a coarse surface finish with excellent durability, making it suitable for packaging but less ideal for high-quality print applications. Bond paper features a smooth surface that enhances print clarity and color vibrancy, providing superior printability for documents and promotional materials. The choice between Kraft and Bond paper impacts print sharpness and ink absorption, influencing the overall visual appeal of printed products.

Durability and Strength

Kraft paper exhibits superior durability and tensile strength compared to bond paper due to its unbleached, coarse fibers and minimal processing, making it ideal for packaging and heavy-duty applications. Bond paper, typically made from refined wood pulp with chemical bleaching, offers smoother texture but lower tear resistance and durability. The high lignin content in kraft paper fibers contributes to its robustness, while bond paper excels in print clarity but is less suited for stress-intensive uses.

Common Uses and Applications

Kraft paper is commonly used for packaging, wrapping, and industrial applications due to its high durability and tear resistance. Bond paper is primarily utilized for writing, printing, and office-related tasks because of its smooth texture and brightness. Both types serve distinct purposes: kraft paper excels in protective and heavy-duty uses, while bond paper is preferred for documents and correspondence.

Environmental Impact and Sustainability

Kraft paper is produced using a chemical pulping process that recycles wood fibers, resulting in higher durability and better biodegradability compared to bond paper, which is typically made from virgin wood pulp with more bleaching chemicals. Kraft paper's lower energy consumption and fewer toxic byproducts during manufacturing contribute to its superior environmental sustainability. Choosing kraft paper reduces carbon footprints and supports eco-friendly packaging solutions, while bond paper's environmental impact is comparatively higher due to resource-intensive production methods.

Cost Comparison

Kraft paper generally offers a lower cost per sheet compared to bond paper due to its production from unbleached wood pulp, which requires fewer processing steps. Bond paper, often made from higher-quality fibers and with added finishes for durability and print clarity, tends to be more expensive but is preferred for official documents and high-quality printing. When budgeting for bulk purchases, Kraft paper is a cost-effective option for packaging and industrial use, whereas bond paper justifies its higher price for professional office applications.

Availability and Customization Options

Kraft paper is widely available in bulk rolls and sheets, favored for its durability and eco-friendly properties, making it ideal for packaging and industrial use. Bond paper, commonly used for office printing and stationery, offers extensive customization options including weight variations, finishes, and brightness levels to suit professional documents. Both papers are accessible through multiple suppliers, but bond paper provides greater flexibility for tailored printing and presentation needs.

Choosing the Right Paper for Your Needs

Kraft paper offers exceptional strength and durability, making it ideal for packaging, wrapping, and heavy-duty applications, while bond paper is smoother and more suitable for printing, writing, and office use. Consider the intended purpose, weight, and texture when selecting between kraft and bond paper to ensure optimal performance and cost-efficiency. Evaluating factors such as tensile strength, absorbency, and finish helps in choosing the right paper for specific projects or everyday tasks.

Kraft paper vs Bond paper Infographic

materialdif.com

materialdif.com