Stone paper is made from calcium carbonate bonded with non-toxic resin, offering a durable and water-resistant alternative to traditional paper derived from wood pulp. Unlike conventional paper production that involves extensive water consumption and chemical processing, stone paper manufacturing is eco-friendly with minimal environmental impact. Its smooth texture and tear resistance make stone paper ideal for applications requiring longevity and sustainability.

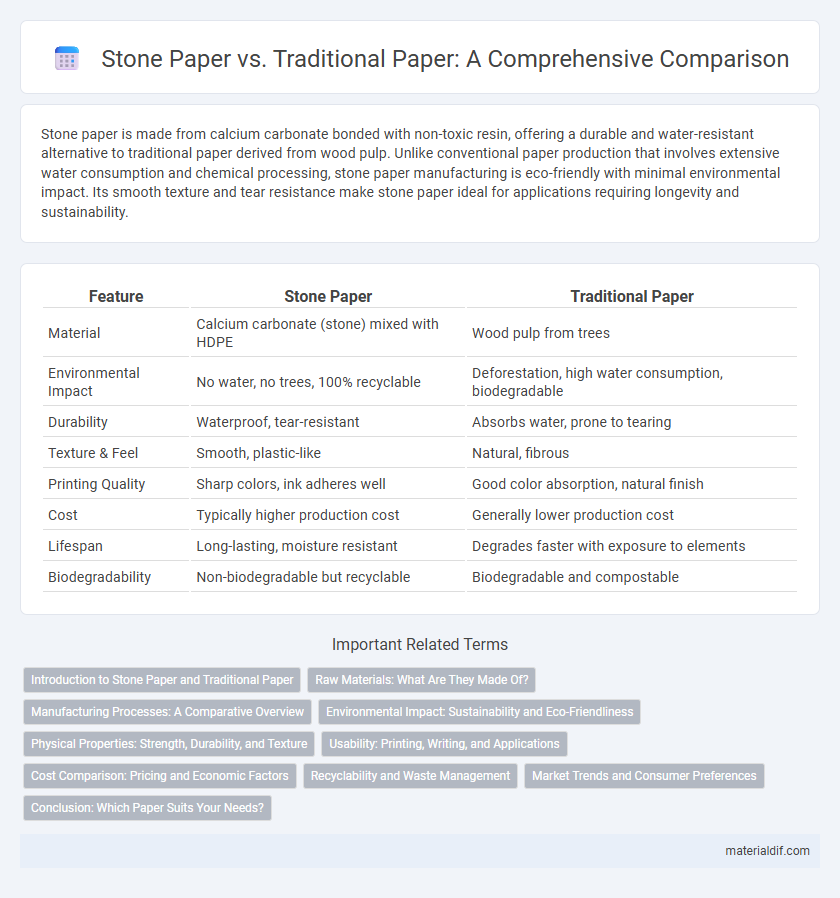

Table of Comparison

| Feature | Stone Paper | Traditional Paper |

|---|---|---|

| Material | Calcium carbonate (stone) mixed with HDPE | Wood pulp from trees |

| Environmental Impact | No water, no trees, 100% recyclable | Deforestation, high water consumption, biodegradable |

| Durability | Waterproof, tear-resistant | Absorbs water, prone to tearing |

| Texture & Feel | Smooth, plastic-like | Natural, fibrous |

| Printing Quality | Sharp colors, ink adheres well | Good color absorption, natural finish |

| Cost | Typically higher production cost | Generally lower production cost |

| Lifespan | Long-lasting, moisture resistant | Degrades faster with exposure to elements |

| Biodegradability | Non-biodegradable but recyclable | Biodegradable and compostable |

Introduction to Stone Paper and Traditional Paper

Stone paper is a sustainable alternative made from crushed limestone bonded with non-toxic resin, offering water-resistant and tear-proof qualities. Traditional paper is produced from wood pulp through a process that involves significant water consumption and chemical treatments, leading to deforestation and environmental concerns. Stone paper's eco-friendly production reduces reliance on trees and water, positioning it as a viable substitute for conventional paper in various applications.

Raw Materials: What Are They Made Of?

Stone paper is made primarily from calcium carbonate, which constitutes about 80% of its composition, combined with a non-toxic resin, typically high-density polyethylene, to bind the materials without requiring water or wood. Traditional paper is produced from cellulose fibers derived mainly from wood pulp, involving extensive processing of trees and chemical treatments. The raw material difference results in stone paper being more sustainable by reducing reliance on deforestation and water usage inherent in traditional paper manufacturing.

Manufacturing Processes: A Comparative Overview

Stone paper manufacturing involves crushing limestone into fine powder mixed with non-toxic resin, resulting in a water-resistant, tear-resistant, and eco-friendly material without using wood pulp or water. Traditional paper production requires wood pulp extracted through chemical or mechanical pulping, followed by extensive water use in processing, bleaching, and drying stages, contributing to high energy consumption and environmental impact. The stone paper process boasts lower water and energy consumption and eliminates the need for harmful chemicals, offering a sustainable alternative to conventional paper manufacturing.

Environmental Impact: Sustainability and Eco-Friendliness

Stone paper offers significant environmental advantages over traditional paper, as it is produced without water, trees, or harmful chemicals, reducing deforestation and water pollution. Its manufacturing process emits fewer greenhouse gases and generates less waste, contributing to lower carbon footprints. Unlike traditional paper, stone paper is durable, recyclable, and biodegradable under the right conditions, promoting long-term sustainability and eco-friendliness.

Physical Properties: Strength, Durability, and Texture

Stone paper exhibits superior strength and durability compared to traditional paper, as it is tear-resistant and waterproof due to its calcium carbonate composition. Unlike traditional cellulose-based paper, stone paper maintains a smooth, plastic-like texture that resists creasing and moisture damage. These physical properties make stone paper an eco-friendly alternative ideal for long-lasting documents and outdoor use.

Usability: Printing, Writing, and Applications

Stone paper offers exceptional durability and water resistance, making it ideal for outdoor printing and writing applications, unlike traditional paper which can easily tear or smear when wet. Its smooth surface enhances print quality and prevents ink bleed, ensuring sharper images and clearer text compared to conventional wood pulp paper. Common applications for stone paper include notebooks, packaging, and maps, where longevity and environmental resistance are critical, whereas traditional paper remains preferred for cost-effective, high-volume printing needs.

Cost Comparison: Pricing and Economic Factors

Stone paper generally costs 20-30% more than traditional wood pulp paper due to the specialized manufacturing process and raw materials like calcium carbonate. However, stone paper reduces expenses related to water usage, chemicals, and energy consumption, offering long-term economic benefits despite its higher initial price. Traditional paper's fluctuating costs are heavily influenced by timber supply and environmental regulations, making stone paper a more stable alternative in procurement and operational expenses.

Recyclability and Waste Management

Stone paper offers superior recyclability compared to traditional paper, as it is made from calcium carbonate bonded with non-toxic resins, allowing it to be recycled multiple times without degrading quality. Traditional paper, composed of wood pulp, often involves chemical treatments and results in fiber degradation, limiting recycling cycles and generating more waste. Waste management of stone paper is more environmentally friendly, producing less water pollution and requiring less energy in the recycling process compared to conventional paper production.

Market Trends and Consumer Preferences

Stone paper, derived from calcium carbonate bonded with non-toxic resin, is gaining market traction due to its eco-friendly and waterproof properties, appealing to environmentally conscious consumers. Traditional paper, produced from wood pulp, maintains dominance in the market owing to established manufacturing infrastructure and affordability, despite environmental concerns. Consumer preferences are shifting toward sustainable alternatives, with stone paper's durability and recyclability driving increased adoption in niches like packaging and stationery.

Conclusion: Which Paper Suits Your Needs?

Stone paper offers enhanced durability, water resistance, and eco-friendly production compared to traditional paper, which is biodegradable yet relies heavily on wood pulp and water-intensive processes. For applications requiring toughness and longevity, such as outdoor use or archival purposes, stone paper proves more suitable. Traditional paper remains ideal for printing and recycling industries prioritizing biodegradability and familiarity.

Stone Paper vs Traditional Paper Infographic

materialdif.com

materialdif.com