Thermal paper is coated with chemicals that react to heat, making it ideal for receipts and labels due to its fast, inkless printing process. Bond paper, known for its durability and smooth finish, is commonly used for official documents, letterheads, and high-quality printing. Thermal paper tends to fade over time and is sensitive to heat, whereas bond paper offers long-lasting print stability and better resistance to environmental factors.

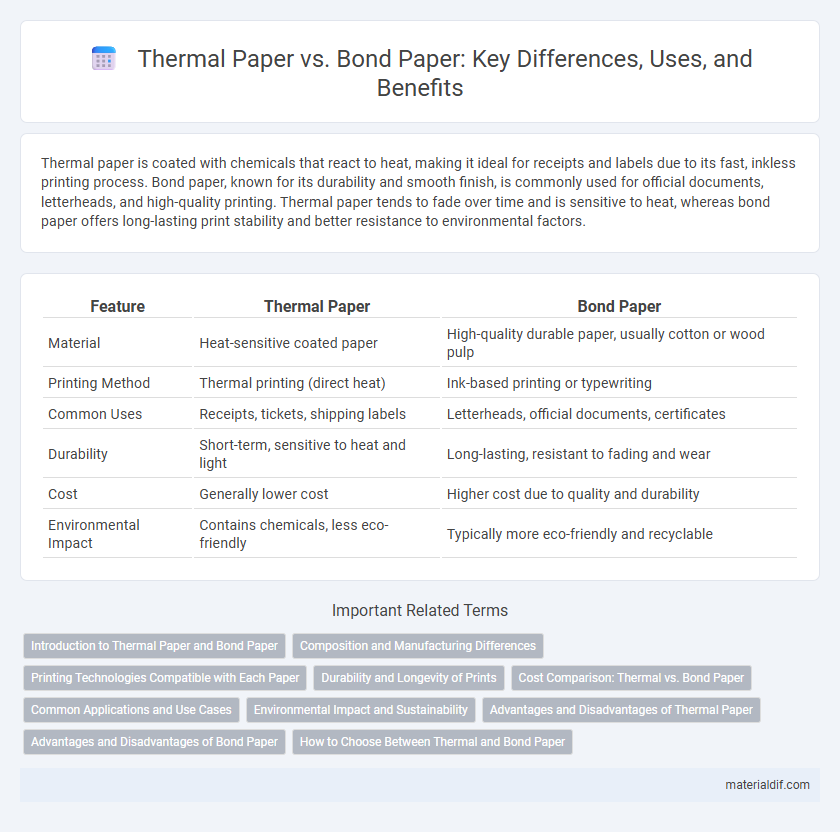

Table of Comparison

| Feature | Thermal Paper | Bond Paper |

|---|---|---|

| Material | Heat-sensitive coated paper | High-quality durable paper, usually cotton or wood pulp |

| Printing Method | Thermal printing (direct heat) | Ink-based printing or typewriting |

| Common Uses | Receipts, tickets, shipping labels | Letterheads, official documents, certificates |

| Durability | Short-term, sensitive to heat and light | Long-lasting, resistant to fading and wear |

| Cost | Generally lower cost | Higher cost due to quality and durability |

| Environmental Impact | Contains chemicals, less eco-friendly | Typically more eco-friendly and recyclable |

Introduction to Thermal Paper and Bond Paper

Thermal paper is coated with a chemical layer that changes color when exposed to heat, making it widely used in receipt printers and fax machines for quick and efficient printing. Bond paper, a high-quality durable paper typically made from cotton or wood pulp, is preferred for official documents, letterheads, and stationary because of its strength and smooth finish. Understanding the distinct properties of thermal and bond paper is essential for selecting the right paper type for specific printing needs.

Composition and Manufacturing Differences

Thermal paper is coated with a chemical layer that changes color when exposed to heat, eliminating the need for ink during printing; it mainly consists of a base paper substrate and a heat-sensitive coating composed of leuco dyes and developers. Bond paper, in contrast, is made from high-quality cotton or wood pulp fibers without any chemical coating, offering durability and smooth texture optimized for writing and printing with ink or toner. Manufacturing thermal paper involves a specialized coating process to apply the heat-reactive layer, whereas bond paper undergoes traditional papermaking steps including pulping, refining, and calendaring to achieve its strength and finish.

Printing Technologies Compatible with Each Paper

Thermal paper is designed specifically for direct thermal printers, utilizing heat-sensitive coatings that react to the printer's thermal head to produce images without ink or toner. Bond paper, compatible with inkjet and laser printers, relies on ink absorption or toner adhesion for printing, making it suitable for high-resolution text and color graphics. The choice between thermal and bond paper hinges on the printing technology used, with thermal paper preferred for receipts and labels, and bond paper favored for office documents and professional printing.

Durability and Longevity of Prints

Thermal paper offers high-quality prints with sharp images but is prone to fading and discoloration over time due to heat and light exposure. Bond paper, made from wood pulp or cotton fibers, provides greater durability and longevity, maintaining print clarity for years without deteriorating. For long-term record-keeping and archival purposes, bond paper is preferred due to its resistance to environmental factors and ink stability.

Cost Comparison: Thermal vs. Bond Paper

Thermal paper generally costs more upfront than bond paper due to its specialized heat-sensitive coating, but it eliminates the need for ink or toner, reducing long-term expenses. Bond paper is cheaper per sheet and compatible with a wider range of printers, yet it requires regular ink or toner replacement, increasing overall operational costs. When evaluating total cost of ownership, businesses must consider printing volume and maintenance expenses to determine the most cost-effective option between thermal and bond paper.

Common Applications and Use Cases

Thermal paper is commonly used in point-of-sale receipts, labels, and tickets due to its heat-sensitive coating that enables fast, inkless printing. Bond paper is preferred for official documents, stationery, and quality printing where durability and ink compatibility are essential. Both papers serve distinct roles in retail, office, and industrial settings based on their printing technology and application requirements.

Environmental Impact and Sustainability

Thermal paper, coated with chemicals like BPA, often poses greater environmental hazards due to its difficulty in recycling and potential toxicity during decomposition, contrasting with bond paper made primarily from untreated or recycled fibers that allows easier recycling and lower ecological footprint. Bond paper production typically consumes more water and energy but benefits from better post-consumer recyclability and biodegradability compared to thermal paper. Choosing bond paper supports sustainability initiatives by reducing harmful chemical waste and promoting circular paper use, whereas thermal paper requires careful disposal to mitigate environmental impact.

Advantages and Disadvantages of Thermal Paper

Thermal paper offers the advantage of fast, quiet printing without the need for ink or toner, making it cost-effective and low-maintenance for receipts and labels. However, thermal paper is sensitive to heat, light, and chemicals, which can cause fading or discoloration over time, limiting its archival quality. In contrast, bond paper provides greater durability and longevity but requires ink and more complex printing equipment, increasing operational costs.

Advantages and Disadvantages of Bond Paper

Bond paper offers high durability and a smooth finish, making it ideal for official documents, letterheads, and stationery due to its superior print quality and resistance to fading. However, it requires ink for printing, which increases operational costs and drying time compared to thermal paper that prints instantly without ink. Bond paper is less suitable for environments requiring quick, heat-sensitive printing, as it cannot be used in thermal printers and is prone to smudging if exposed to moisture.

How to Choose Between Thermal and Bond Paper

Choosing between thermal and bond paper depends on the printing method and application requirements; thermal paper is ideal for direct thermal printers, offering fast, high-quality prints without ink, while bond paper suits impact or inkjet printers, providing durability and compatibility with various inks. Consider factors such as print longevity, environmental exposure, and cost-effectiveness; thermal paper tends to fade over time and is sensitive to heat and light, whereas bond paper maintains print stability and resists wear. Evaluate the specific use case, including receipt printing, archival needs, or official documentation, to ensure optimal material selection aligned with performance and budget constraints.

Thermal paper vs Bond paper Infographic

materialdif.com

materialdif.com