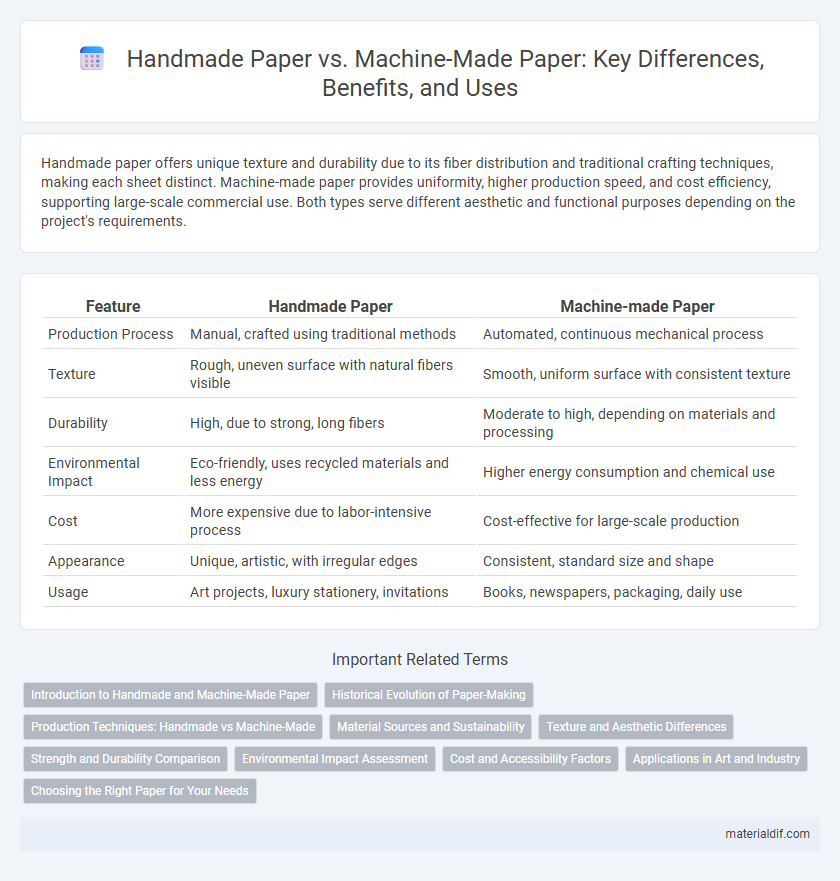

Handmade paper offers unique texture and durability due to its fiber distribution and traditional crafting techniques, making each sheet distinct. Machine-made paper provides uniformity, higher production speed, and cost efficiency, supporting large-scale commercial use. Both types serve different aesthetic and functional purposes depending on the project's requirements.

Table of Comparison

| Feature | Handmade Paper | Machine-made Paper |

|---|---|---|

| Production Process | Manual, crafted using traditional methods | Automated, continuous mechanical process |

| Texture | Rough, uneven surface with natural fibers visible | Smooth, uniform surface with consistent texture |

| Durability | High, due to strong, long fibers | Moderate to high, depending on materials and processing |

| Environmental Impact | Eco-friendly, uses recycled materials and less energy | Higher energy consumption and chemical use |

| Cost | More expensive due to labor-intensive process | Cost-effective for large-scale production |

| Appearance | Unique, artistic, with irregular edges | Consistent, standard size and shape |

| Usage | Art projects, luxury stationery, invitations | Books, newspapers, packaging, daily use |

Introduction to Handmade and Machine-Made Paper

Handmade paper is crafted through traditional, manual processes involving natural fibers such as cotton or hemp, resulting in unique textures and irregularities that signify its artisanal quality. Machine-made paper, produced on industrial scale using automated processes and wood pulp, offers consistent thickness, smooth surface, and higher production speed. Both types serve distinct purposes, with handmade paper preferred for artistic and archival uses due to its durability and aesthetic appeal, while machine-made paper dominates commercial printing and packaging industries.

Historical Evolution of Paper-Making

Handmade paper originated thousands of years ago, first developed in ancient China during the Han Dynasty around 105 AD, where artisans meticulously crafted sheets from plant fibers using mold and deckle techniques. Machine-made paper emerged during the Industrial Revolution in the 19th century, with inventions like the Fourdrinier machine enabling continuous, high-speed production and transforming the paper industry by significantly increasing output and reducing costs. The historical evolution from handmade to machine-made paper reflects advancements in technology, shifting from labor-intensive processes to mechanized manufacturing that met the demands of growing literacy and industrialization worldwide.

Production Techniques: Handmade vs Machine-Made

Handmade paper production involves traditional methods where fibers are manually soaked, beaten, and pressed using molds and deckles, resulting in unique textures and irregularities. Machine-made paper utilizes high-speed continuous machines, such as Fourdrinier or cylinder molds, ensuring consistent thickness, smoothness, and large-scale output. The mechanized process enables rapid production but often sacrifices the distinctive artisanal qualities found in handmade paper.

Material Sources and Sustainability

Handmade paper is typically crafted from recycled cotton, hemp, or other plant fibers, using natural and biodegradable materials that enhance its sustainability profile. Machine-made paper, largely produced from wood pulp sourced from commercial forestry operations, often involves chemical treatments and higher energy consumption, impacting its environmental footprint. The reliance on renewable, non-wood fibers in handmade paper offers superior biodegradability and reduced ecological damage compared to the resource-intensive processes of machine-made paper production.

Texture and Aesthetic Differences

Handmade paper exhibits a unique, uneven texture with visible fibers and natural deckle edges, creating an artisanal, organic aesthetic highly valued in fine art and craft applications. Machine-made paper typically has a uniform, smooth surface with precise edges, offering consistency and suitability for mass production and commercial use. The tactile quality of handmade paper enhances visual depth and character, whereas machine-made paper prioritizes efficiency and standardized appearance.

Strength and Durability Comparison

Handmade paper typically exhibits superior strength and durability due to its longer, untreated fibers and traditional crafting techniques that create a dense fiber network. Machine-made paper often has shorter fibers and includes chemical additives, which can reduce tensile strength and make it more prone to wear over time. The inherent fiber arrangement in handmade paper results in enhanced tear resistance and longevity compared to the more uniform but weaker structure of machine-produced paper.

Environmental Impact Assessment

Handmade paper exhibits a significantly lower environmental footprint compared to machine-made paper, primarily due to its use of natural fibers and minimal chemical processing, which reduces water and air pollution. Machine-made paper production consumes high amounts of energy and large quantities of water, contributing to deforestation and carbon emissions on a global scale. Lifecycle assessments reveal that handmade paper supports sustainable practices by promoting renewable raw materials and generating less industrial waste.

Cost and Accessibility Factors

Handmade paper typically incurs higher production costs due to labor-intensive processes and limited scale, making it less accessible and more expensive than machine-made paper. Machine-made paper benefits from automated, high-volume manufacturing, resulting in lower costs and widespread availability in various grades and sizes. Cost differences significantly influence buyer choice, with handmade paper favored for artisanal or specialty uses and machine-made paper dominating mass-market applications.

Applications in Art and Industry

Handmade paper, prized for its unique texture and durability, is widely used in fine arts, including calligraphy, printmaking, and custom stationery, where aesthetic quality and archival properties are essential. Machine-made paper offers consistent thickness and surface smoothness, making it ideal for mass-produced products in industries such as packaging, publishing, and commercial printing. Artisans and manufacturers select paper types based on the balance between visual appeal, tactile experience, and production scalability to suit specific artistic and industrial demands.

Choosing the Right Paper for Your Needs

Handmade paper offers unique texture, durability, and eco-friendly qualities ideal for artistic projects or luxury stationery, while machine-made paper provides consistency, affordability, and scalability for bulk printing and commercial use. Consider factors such as paper weight, finish, absorption, and environmental impact when selecting between handmade and machine-made options. Assessing your project's purpose ensures you choose the right paper that balances aesthetics, functionality, and cost-effectiveness.

Handmade paper vs Machine-made paper Infographic

materialdif.com

materialdif.com