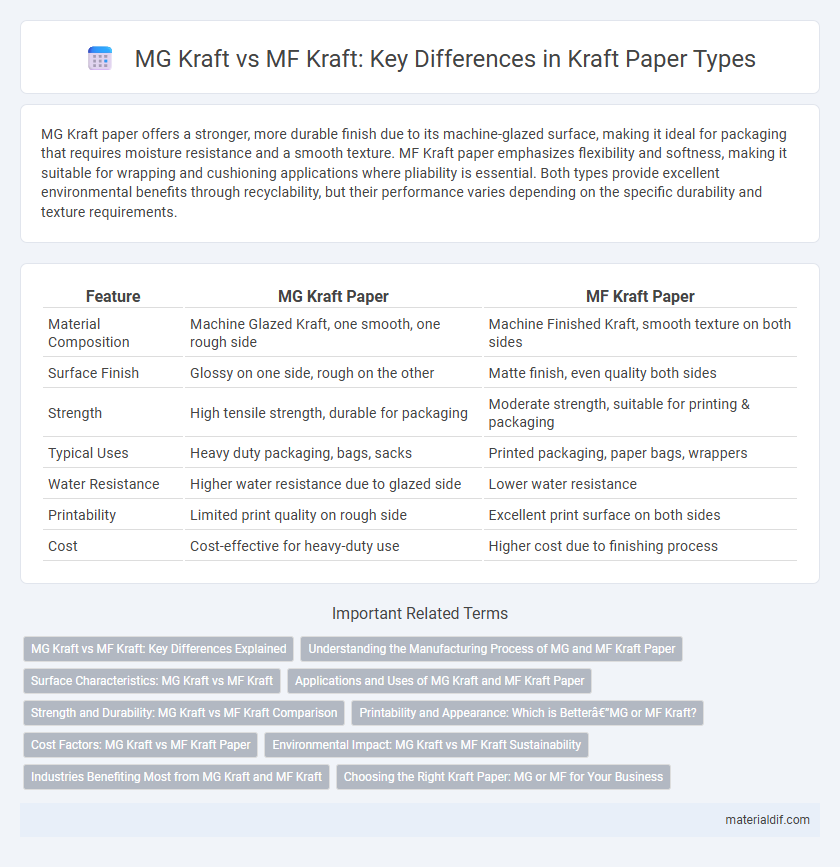

MG Kraft paper offers a stronger, more durable finish due to its machine-glazed surface, making it ideal for packaging that requires moisture resistance and a smooth texture. MF Kraft paper emphasizes flexibility and softness, making it suitable for wrapping and cushioning applications where pliability is essential. Both types provide excellent environmental benefits through recyclability, but their performance varies depending on the specific durability and texture requirements.

Table of Comparison

| Feature | MG Kraft Paper | MF Kraft Paper |

|---|---|---|

| Material Composition | Machine Glazed Kraft, one smooth, one rough side | Machine Finished Kraft, smooth texture on both sides |

| Surface Finish | Glossy on one side, rough on the other | Matte finish, even quality both sides |

| Strength | High tensile strength, durable for packaging | Moderate strength, suitable for printing & packaging |

| Typical Uses | Heavy duty packaging, bags, sacks | Printed packaging, paper bags, wrappers |

| Water Resistance | Higher water resistance due to glazed side | Lower water resistance |

| Printability | Limited print quality on rough side | Excellent print surface on both sides |

| Cost | Cost-effective for heavy-duty use | Higher cost due to finishing process |

MG Kraft vs MF Kraft: Key Differences Explained

MG Kraft features a smooth, coated surface ideal for high-quality printing, while MF Kraft offers a rougher texture suitable for general packaging needs. MG Kraft is typically used in applications requiring superior print clarity and appearance, whereas MF Kraft provides enhanced durability and strength for wrapping and cushioning. The choice between MG and MF Kraft depends on the balance between aesthetic appeal and functional performance in paper products.

Understanding the Manufacturing Process of MG and MF Kraft Paper

MG kraft paper undergoes a specialized manufacturing process involving the treatment of one side with a coating or sizing agent to enhance smoothness and printability, making it ideal for applications requiring a high-quality surface. MF kraft paper, or machine-finished kraft, is produced by drying the paper on a smooth cylinder without additional surface treatment, resulting in a rougher texture with greater tensile strength. Understanding these differences helps optimize paper selection based on printing needs and mechanical performance.

Surface Characteristics: MG Kraft vs MF Kraft

MG Kraft paper typically exhibits a smooth and uniform surface due to its machine-glazed process, resulting in enhanced printability and reduced ink absorption. MF Kraft paper features a more fibrous and porous surface, providing superior strength and better adhesion for coatings and laminates. Differences in surface roughness and porosity between MG and MF Kraft significantly influence their suitability for packaging, printing, and finishing applications.

Applications and Uses of MG Kraft and MF Kraft Paper

MG Kraft paper offers a smooth surface ideal for high-quality printing, making it widely used in packaging for luxury goods, food wrapping, and retail shopping bags. MF Kraft paper, with its coarser texture and higher absorbency, is commonly utilized for industrial purposes such as heavy-duty wrapping, corrugated board, and construction materials. The distinct fiber compositions of MG and MF Kraft papers dictate their suitability for specific applications, enhancing durability, print clarity, or moisture resistance as required.

Strength and Durability: MG Kraft vs MF Kraft Comparison

MG Kraft paper exhibits superior tensile strength due to its machine-gloss finish, which enhances fiber bonding and provides a more uniform surface. In contrast, MF Kraft offers greater durability through its multi-fold layering, making it more resistant to tearing and punctures. Both types serve well in packaging, but MG Kraft is preferred for applications requiring smooth surfaces and printability, while MF Kraft excels in high-strength protective uses.

Printability and Appearance: Which is Better—MG or MF Kraft?

MG Kraft paper features a smooth, fine surface due to its machine-glazed finish, enhancing print clarity and sharpness for high-quality images and text. MF Kraft paper has a matte finish with a slightly rough texture that absorbs ink differently, offering a natural look but potentially less print precision. For applications demanding superior printability and crisp appearance, MG Kraft is generally preferred over MF Kraft.

Cost Factors: MG Kraft vs MF Kraft Paper

MG Kraft paper typically incurs lower production costs due to its single-ply structure and simpler manufacturing process, making it more affordable for bulk packaging applications. MF Kraft paper, composed of multiple plies, involves higher raw material consumption and energy usage, resulting in elevated production expenses but enhanced strength and durability. Cost considerations between MG and MF Kraft paper often influence product selection based on budget constraints and required performance characteristics.

Environmental Impact: MG Kraft vs MF Kraft Sustainability

MG Kraft paper, produced from 100% virgin fibers, offers high strength but involves higher environmental costs due to deforestation and energy-intensive pulping processes. MF Kraft, typically made from recycled fibers, significantly reduces waste and lowers carbon emissions by minimizing reliance on virgin pulp and promoting circular economy practices. Choosing MF Kraft supports sustainability goals by decreasing water use and chemical pollutants compared to traditional MG Kraft manufacturing.

Industries Benefiting Most from MG Kraft and MF Kraft

MG Kraft pulp, characterized by its long fibers, is predominantly used in industries requiring strong, durable paper products such as packaging, corrugated boxes, and industrial sacks where tear resistance and tensile strength are critical. MF Kraft pulp, with its shorter fibers, is favored in the production of printing and writing papers, tissue products, and specialty papers that demand smoothness and printability. Both MG and MF Kraft are essential in the paper industry; however, MG Kraft benefits heavy-duty packaging and construction industries, while MF Kraft serves publishing, hygiene, and fine paper markets.

Choosing the Right Kraft Paper: MG or MF for Your Business

MG Kraft paper, featuring a machine-glazed smooth finish, offers superior printability and moisture resistance, making it ideal for high-quality packaging and labels. MF Kraft paper provides a coarser texture with smoothness on one side, suitable for applications requiring better print receptivity and improved strength. Selecting between MG and MF Kraft depends on your business needs for durability, print quality, and cost-effectiveness in packaging or wrapping solutions.

MG Kraft vs MF Kraft Infographic

materialdif.com

materialdif.com