Paper calendaring enhances surface smoothness and gloss by passing sheets between rollers under pressure, improving print quality and tactile appeal. Paper embossing creates raised designs or patterns on the paper surface, adding texture and decorative elements that increase visual interest and tactile experience. Choosing between calendaring and embossing depends on whether a smooth finish or textured embellishment best suits the intended paper application.

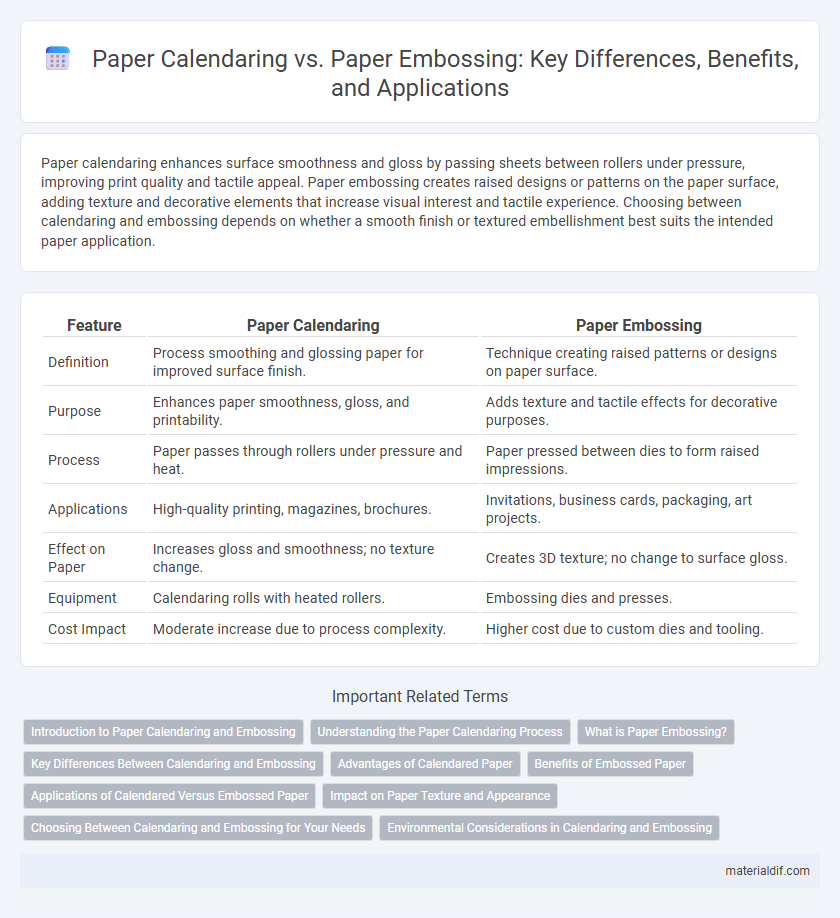

Table of Comparison

| Feature | Paper Calendaring | Paper Embossing |

|---|---|---|

| Definition | Process smoothing and glossing paper for improved surface finish. | Technique creating raised patterns or designs on paper surface. |

| Purpose | Enhances paper smoothness, gloss, and printability. | Adds texture and tactile effects for decorative purposes. |

| Process | Paper passes through rollers under pressure and heat. | Paper pressed between dies to form raised impressions. |

| Applications | High-quality printing, magazines, brochures. | Invitations, business cards, packaging, art projects. |

| Effect on Paper | Increases gloss and smoothness; no texture change. | Creates 3D texture; no change to surface gloss. |

| Equipment | Calendaring rolls with heated rollers. | Embossing dies and presses. |

| Cost Impact | Moderate increase due to process complexity. | Higher cost due to custom dies and tooling. |

Introduction to Paper Calendaring and Embossing

Paper calendaring enhances surface smoothness and gloss by pressing paper through polished rollers, improving printability and tactile appeal. Embossing creates raised or recessed designs by applying pressure with engraved dies, adding texture and visual interest without altering paper thickness significantly. Both techniques are essential in paper finishing, with calendaring focusing on surface properties and embossing emphasizing decorative effects.

Understanding the Paper Calendaring Process

The paper calendaring process involves passing paper through a series of rollers to enhance surface smoothness, gloss, and density, thereby improving printability and overall quality. Unlike embossing, which creates a raised or textured design on the paper surface, calendaring achieves a uniform finish that enhances paper strength and opacity. This process is critical in producing high-grade paper used in printing, packaging, and writing applications.

What is Paper Embossing?

Paper embossing is a technique that creates raised designs or patterns on paper by pressing it between engraved metal plates or rollers. This process enhances the tactile quality and visual appeal of printed materials, often used for invitations, business cards, and packaging. Unlike calendaring, which smooths and compresses paper fibers for uniform surface finish, embossing adds dimensional texture without altering the paper's thickness significantly.

Key Differences Between Calendaring and Embossing

Calendaring involves passing paper through rollers to smooth and compress the surface, enhancing gloss and uniformity, while embossing creates raised or recessed patterns by pressing designs into the paper, adding texture and visual appeal. Calendaring primarily improves paper density and surface finish, making it ideal for high-quality printing processes, whereas embossing alters the paper's tactile features for decorative or branding purposes. The choice between calendaring and embossing depends on whether the priority is surface smoothness and printability or texture and aesthetic enhancement.

Advantages of Calendared Paper

Calendared paper offers a smooth, glossy surface that enhances print clarity and color vibrancy, making it ideal for high-quality printing applications. Its uniform finish improves folding and reduces ink absorption, resulting in sharper images and text. Compared to paper embossing, calendared paper provides a consistent texture without compromising the durability or flexibility of the material.

Benefits of Embossed Paper

Embossed paper offers enhanced tactile appeal and a sophisticated three-dimensional texture that elevates the visual impact of printed materials. This technique improves durability by adding structural integrity, making embossed designs more resistant to wear and tear compared to calendared paper surfaces. Embossing also enhances perceived value and brand recognition, making it ideal for premium packaging, business cards, and luxury stationery.

Applications of Calendared Versus Embossed Paper

Calendared paper offers a smooth, glossy finish ideal for high-quality printing applications such as magazines, brochures, and photographic prints where sharp image reproduction is critical. Embossed paper features raised patterns or textures that enhance tactile appeal, making it suitable for luxury packaging, invitations, and business cards that require a distinctive, elegant look. Choosing calendared versus embossed paper depends on the desired visual effect and texture, influencing the paper's suitability for specific commercial or artistic projects.

Impact on Paper Texture and Appearance

Paper calendaring involves passing paper through rollers to smooth and compress fibers, resulting in a glossy, uniform surface that enhances print clarity and tactile smoothness. Paper embossing creates raised or recessed patterns by pressing designs into the paper, adding dimensional texture that enhances visual interest and tactile appeal. While calendaring emphasizes sleekness and reflectivity, embossing focuses on texture and depth, significantly affecting both the paper's appearance and the sensory experience.

Choosing Between Calendaring and Embossing for Your Needs

Selecting between paper calendaring and embossing depends on the desired texture and finish; calendaring produces a smooth, glossy surface by passing paper through heated rollers, enhancing printability and visual appeal. Embossing creates a raised or recessed design, adding tactile dimension and depth that emphasizes logos or patterns for premium branding. Understanding your project's functional and aesthetic goals helps determine whether a sleek, polished look or a textured, three-dimensional effect better suits your needs.

Environmental Considerations in Calendaring and Embossing

Paper calendaring involves smoothing and compressing paper fibers to achieve a polished finish, which can reduce porosity and improve printability while typically requiring less energy and water compared to embossing. Paper embossing raises patterns or textures onto the paper surface, enhancing tactile qualities but often consuming more energy due to the mechanical pressure and heat involved. Environmentally, calendaring tends to have a lower carbon footprint and produces less waste, making it a more sustainable option in paper finishing processes.

Paper calendaring vs Paper embossing Infographic

materialdif.com

materialdif.com