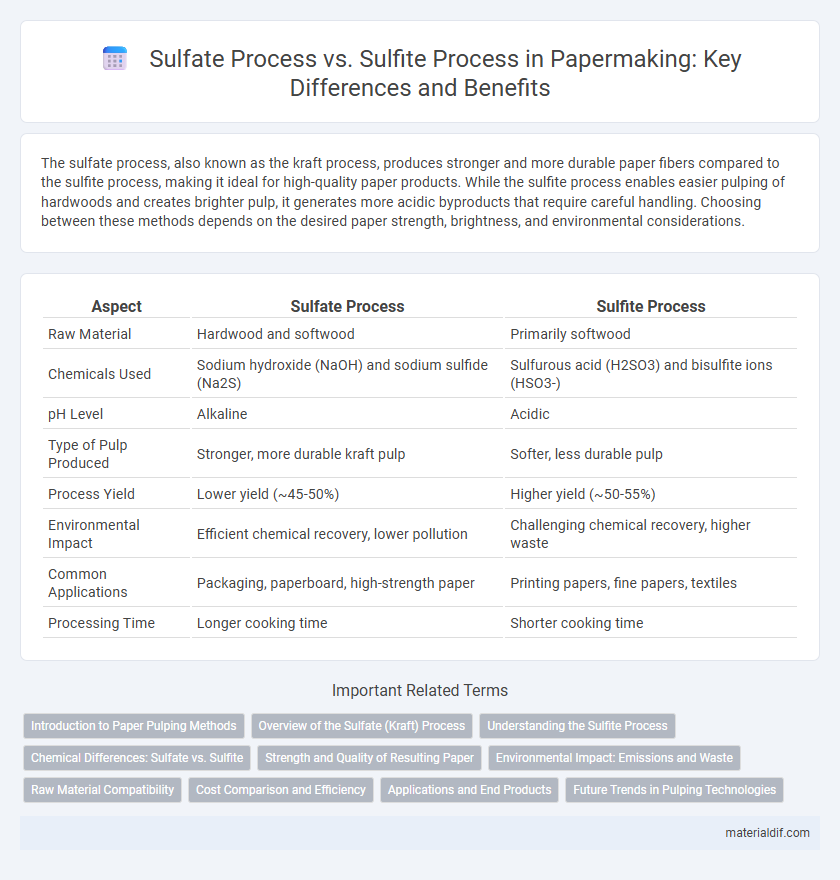

The sulfate process, also known as the kraft process, produces stronger and more durable paper fibers compared to the sulfite process, making it ideal for high-quality paper products. While the sulfite process enables easier pulping of hardwoods and creates brighter pulp, it generates more acidic byproducts that require careful handling. Choosing between these methods depends on the desired paper strength, brightness, and environmental considerations.

Table of Comparison

| Aspect | Sulfate Process | Sulfite Process |

|---|---|---|

| Raw Material | Hardwood and softwood | Primarily softwood |

| Chemicals Used | Sodium hydroxide (NaOH) and sodium sulfide (Na2S) | Sulfurous acid (H2SO3) and bisulfite ions (HSO3-) |

| pH Level | Alkaline | Acidic |

| Type of Pulp Produced | Stronger, more durable kraft pulp | Softer, less durable pulp |

| Process Yield | Lower yield (~45-50%) | Higher yield (~50-55%) |

| Environmental Impact | Efficient chemical recovery, lower pollution | Challenging chemical recovery, higher waste |

| Common Applications | Packaging, paperboard, high-strength paper | Printing papers, fine papers, textiles |

| Processing Time | Longer cooking time | Shorter cooking time |

Introduction to Paper Pulping Methods

The sulfate process, also known as the Kraft process, uses sodium hydroxide and sodium sulfide to break down lignin in wood, producing stronger and more durable pulp compared to the sulfite process, which employs sulfurous acid and bisulfite ions. The sulfite process is more suitable for producing fine, soft paper due to its ability to remove lignin more selectively, though it generally yields weaker fibers. Both methods are central to paper pulping, influencing the physical properties and applications of the final paper products.

Overview of the Sulfate (Kraft) Process

The Sulfate (Kraft) process is the dominant method for producing wood pulp, characterized by its use of sodium hydroxide and sodium sulfide to break down lignin in wood chips. This process efficiently yields strong, high-quality pulp suitable for a wide range of paper products, offering superior fiber strength compared to the Sulfite process. Its robustness and adaptability to various wood types make the Kraft process the preferred choice in modern pulp and paper manufacturing.

Understanding the Sulfite Process

The sulfite process involves treating wood chips with sulfurous acid and bisulfite ions to break down lignin, producing high-quality pulp primarily used for fine paper production. This method offers superior pulp brightness and strength but operates under lower pH conditions compared to the sulfate process, which employs a more alkaline environment and predominantly uses sodium hydroxide and sodium sulfide. Understanding the chemical mechanisms and operational parameters of the sulfite process is critical for optimizing pulp yield and quality in specialized paper manufacturing.

Chemical Differences: Sulfate vs. Sulfite

The sulfate process utilizes sulfurous acid and sodium sulfide to break down lignin, resulting in stronger and more durable pulp due to the presence of sulfate ions. The sulfite process employs sulfur dioxide dissolved in water, forming bisulfite or sulfite ions that selectively target lignin, producing softer pulp suited for finer paper qualities. Chemical differences between sulfate and sulfite processes influence pulp composition, strength, and bleaching requirements, with sulfate pulps typically exhibiting higher resistance to further chemical treatment.

Strength and Quality of Resulting Paper

The sulfate process produces stronger and more durable paper due to its ability to break down lignin more effectively, resulting in higher cellulose purity and fiber strength. In contrast, the sulfite process yields paper with a smoother texture and better printability but generally lower tensile strength and durability. Paper made from the sulfate process is preferred for packaging and industrial uses, while sulfite pulp is often used in fine printing and writing papers.

Environmental Impact: Emissions and Waste

The sulfate process generates higher amounts of sulfur dioxide (SO2) emissions compared to the sulfite process, contributing significantly to air pollution and acid rain. Waste from the sulfate process contains primarily lignin and can be efficiently burned for energy recovery, reducing solid waste output. In contrast, the sulfite process produces wastewater with higher biochemical oxygen demand (BOD), posing greater challenges for water treatment and aquatic ecosystem health.

Raw Material Compatibility

The sulfate process is compatible with a wider range of raw materials, including both hardwoods and softwoods, due to its ability to break down lignin more effectively at higher pH levels. In contrast, the sulfite process is primarily suited for softwoods and certain hardwoods that are less resistant, as its acidic conditions limit raw material versatility. This difference in raw material compatibility affects pulp yield, fiber quality, and overall process efficiency.

Cost Comparison and Efficiency

The sulfate process generally offers higher efficiency and produces stronger pulp compared to the sulfite process, making it preferable for processing hardwoods and softwoods. While the sulfite process can be more cost-effective for certain applications due to lower chemical costs and simpler recovery systems, it tends to have higher operational expenses stemming from slower cooking times and less efficient chemical recovery. Overall, the sulfate process provides better long-term economic benefits through higher yield, stronger fiber quality, and effective chemical recovery, despite its initially higher capital investment.

Applications and End Products

The sulfate process primarily produces kraft pulp, which yields stronger, more durable paper suitable for packaging, printing, and writing applications. The sulfite process generates pulp with higher brightness and better softness, making it ideal for producing fine paper products like tissues, newspapers, and writing paper. Both processes contribute significantly to the paper industry, with sulfate pulp favored for strength-intensive uses and sulfite pulp chosen for quality and printability.

Future Trends in Pulping Technologies

Future trends in pulping technologies emphasize the development of more sustainable and efficient methods, with the sulfate process gaining preference due to its superior lignin removal and chemical recovery capabilities compared to the sulfite process. Innovations in enzymatic pretreatment and the integration of green solvents enhance the sulfate method's environmental performance and energy efficiency. Research also focuses on hybrid processes combining sulfate and sulfite techniques to optimize pulp quality and reduce ecological impact.

Sulfate process vs Sulfite process Infographic

materialdif.com

materialdif.com