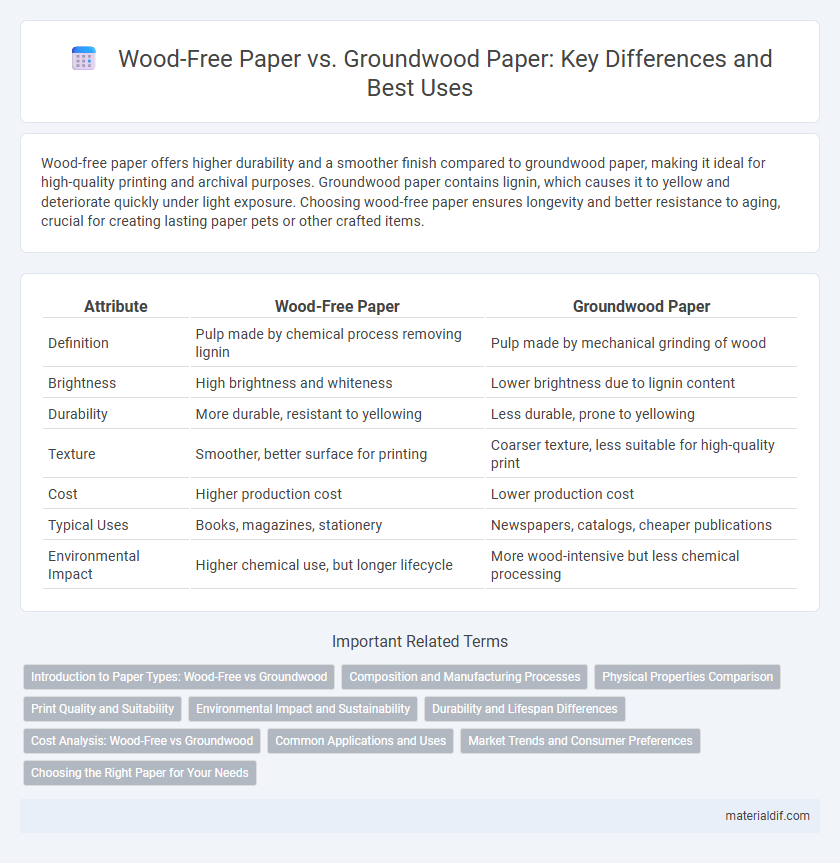

Wood-free paper offers higher durability and a smoother finish compared to groundwood paper, making it ideal for high-quality printing and archival purposes. Groundwood paper contains lignin, which causes it to yellow and deteriorate quickly under light exposure. Choosing wood-free paper ensures longevity and better resistance to aging, crucial for creating lasting paper pets or other crafted items.

Table of Comparison

| Attribute | Wood-Free Paper | Groundwood Paper |

|---|---|---|

| Definition | Pulp made by chemical process removing lignin | Pulp made by mechanical grinding of wood |

| Brightness | High brightness and whiteness | Lower brightness due to lignin content |

| Durability | More durable, resistant to yellowing | Less durable, prone to yellowing |

| Texture | Smoother, better surface for printing | Coarser texture, less suitable for high-quality print |

| Cost | Higher production cost | Lower production cost |

| Typical Uses | Books, magazines, stationery | Newspapers, catalogs, cheaper publications |

| Environmental Impact | Higher chemical use, but longer lifecycle | More wood-intensive but less chemical processing |

Introduction to Paper Types: Wood-Free vs Groundwood

Wood-free paper, primarily composed of chemical pulp, offers higher brightness, durability, and smoothness due to the removal of lignin during processing. Groundwood paper, made from mechanical pulp that retains lignin, features a lower production cost but tends to yellow and degrade faster over time. Understanding these differences aids in selecting the appropriate paper type for printing, publishing, and packaging applications based on quality and longevity requirements.

Composition and Manufacturing Processes

Wood-free paper consists primarily of chemical pulp made by removing lignin from wood fibers, resulting in higher brightness and durability, while groundwood paper is produced by mechanically grinding wood logs, retaining most lignin and causing lower brightness and faster yellowing. The chemical pulping process in wood-free paper involves kraft or sulfite methods, which break down lignin to isolate cellulose fibers, whereas groundwood paper manufacturing uses mechanical refiners or grinders that physically separate fibers without chemical treatment. These compositional and processing differences influence the paper's strength, printability, and longevity, making wood-free paper suitable for high-quality printing and groundwood paper ideal for economical mass production.

Physical Properties Comparison

Wood-free paper, typically made from chemical pulp, exhibits higher brightness, smoothness, and durability compared to groundwood paper, which contains mechanical pulp with lignin. Groundwood paper generally has lower strength, increased porosity, and tends to yellow faster due to lignin content. These differences make wood-free paper preferable for printing applications requiring longevity and high-quality image reproduction.

Print Quality and Suitability

Wood-free paper, also known as chemical pulp paper, offers superior print quality due to its smoother surface and higher brightness, making it ideal for high-resolution images and professional documents. Groundwood paper, produced from mechanically ground wood fibers, has a rougher texture and lower brightness, which limits its print quality but makes it suitable for economical printing tasks like newspapers and flyers. The choice between these papers depends on the balance between print quality requirements and budget considerations.

Environmental Impact and Sustainability

Wood-free paper, typically produced from fully bleached chemical pulp, offers higher recyclability and lower environmental impact compared to groundwood paper, which contains mechanical pulp with lignin that causes faster degradation and yellowing. Groundwood paper requires less energy to manufacture but has a shorter lifespan and lower recyclability, increasing landfill waste and environmental burden. Sustainable choices favor wood-free paper due to its enhanced durability, recyclability, and reduced chemical residues, supporting longer product life cycles and reduced ecological footprint.

Durability and Lifespan Differences

Wood-free paper, made from chemical pulp, offers superior durability and a longer lifespan due to its higher resistance to yellowing and deterioration over time. Groundwood paper, produced using mechanical pulp, contains lignin that accelerates aging and causes the paper to become brittle and degrade faster. For archival purposes and long-term use, wood-free paper is the preferred choice because of its enhanced stability and strength.

Cost Analysis: Wood-Free vs Groundwood

Wood-free paper generally incurs higher production costs due to the extensive chemical pulping and bleaching processes required, while groundwood paper benefits from lower expenses as it uses mechanical pulping with minimal chemical treatment. The higher fiber quality and durability of wood-free paper justify its elevated market price, making it ideal for premium printing applications despite the increased cost. Groundwood paper, though cost-effective and suitable for high-volume, short-lifespan print runs like newspapers, often sacrifices brightness and longevity, impacting its overall value proposition.

Common Applications and Uses

Wood-free paper, primarily composed of chemical pulp, is commonly used for high-quality printing, books, and office stationery due to its smooth texture and durability. Groundwood paper, containing mechanical pulp, is favored for newspapers, catalogs, and flyers because of its cost-effectiveness and ability to absorb ink quickly. Both paper types serve essential roles in publishing and packaging industries, tailored to specific print and usage requirements.

Market Trends and Consumer Preferences

Wood-free paper dominates the market due to its higher quality, durability, and preferred use in printing and writing applications, driving steady demand growth. Groundwood paper remains popular for budget-conscious consumers and packaging, benefiting from cost efficiency and sustainability trends favoring recycled fibers. Market analysis reveals a shift toward wood-free paper in developed regions, while emerging markets sustain groundwood paper use due to affordability and rapid industrialization.

Choosing the Right Paper for Your Needs

Wood-free paper offers higher durability, brightness, and printing quality, making it ideal for professional documents, books, and high-end printing projects. Groundwood paper is more economical and commonly used for newspapers and flyers, providing good opacity but lower longevity due to its higher lignin content. Selecting the right paper depends on the balance between budget, print quality, and intended paper lifespan for your specific requirements.

Wood-free paper vs Groundwood paper Infographic

materialdif.com

materialdif.com