Wet strength paper is specially treated to maintain its durability and resist tearing when exposed to moisture, making it ideal for applications like packaging, labels, and maps that encounter wet conditions. Regular strength paper lacks this enhanced resistance, causing it to weaken and disintegrate more easily when wet. Choosing wet strength paper ensures longevity and reliability in environments where moisture is a factor.

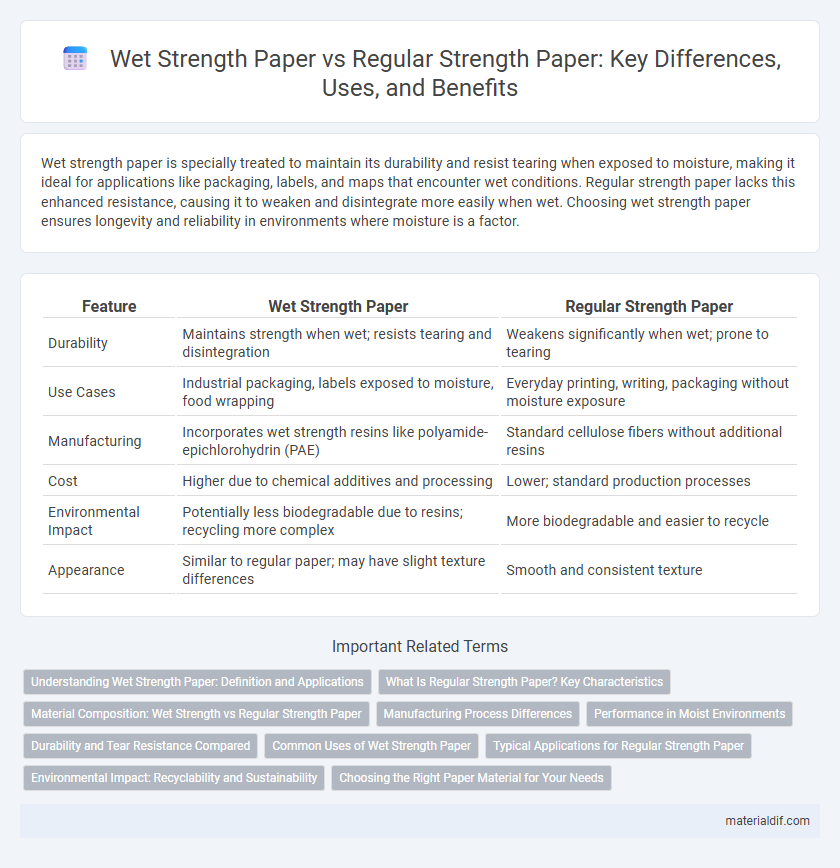

Table of Comparison

| Feature | Wet Strength Paper | Regular Strength Paper |

|---|---|---|

| Durability | Maintains strength when wet; resists tearing and disintegration | Weakens significantly when wet; prone to tearing |

| Use Cases | Industrial packaging, labels exposed to moisture, food wrapping | Everyday printing, writing, packaging without moisture exposure |

| Manufacturing | Incorporates wet strength resins like polyamide-epichlorohydrin (PAE) | Standard cellulose fibers without additional resins |

| Cost | Higher due to chemical additives and processing | Lower; standard production processes |

| Environmental Impact | Potentially less biodegradable due to resins; recycling more complex | More biodegradable and easier to recycle |

| Appearance | Similar to regular paper; may have slight texture differences | Smooth and consistent texture |

Understanding Wet Strength Paper: Definition and Applications

Wet strength paper is specially engineered to maintain its integrity and resist disintegration when exposed to water or moisture, utilizing chemical additives such as polyamide-epichlorohydrin (PAE) resin to enhance fiber bonding. This type of paper finds critical applications in packaging for food products, pharmaceuticals, and industrial materials where durability and resistance to moisture are essential. Unlike regular strength paper, which loses structural strength upon wetting, wet strength paper is essential for functional uses that require exposure to high humidity or direct contact with liquids.

What Is Regular Strength Paper? Key Characteristics

Regular strength paper is a standard paper type designed primarily for dry applications, offering moderate durability and tensile strength suitable for everyday printing, writing, and packaging tasks. It typically consists of cellulose fibers untreated by water-resistant chemicals, resulting in limited resistance to moisture and reduced structural integrity when wet. Common applications include office documents, books, and lightweight packaging where high wet strength is not a critical requirement.

Material Composition: Wet Strength vs Regular Strength Paper

Wet strength paper incorporates specialized resins such as polyamide-epichlorohydrin (PAE) that enhance fiber bonding and resist disintegration when exposed to moisture. Regular strength paper primarily relies on hydrogen bonding between cellulose fibers without added chemical reinforcements, making it prone to weakening when wet. The inclusion of wet strength agents in wet strength paper significantly improves durability in high-humidity or liquid-contact applications.

Manufacturing Process Differences

Wet strength paper is created using specialized resins such as polyamide-epichlorohydrin that reinforce fiber bonds during the paper manufacturing process, enabling it to retain strength and integrity when exposed to moisture. Regular strength paper primarily relies on hydrogen bonding between cellulose fibers without the incorporation of wet-strength additives, making it more susceptible to weakening and disintegration when wet. The wet strength paper production involves additional coating or impregnation stages that enhance water resistance, whereas regular paper manufacturing emphasizes fiber bonding under dry conditions without these chemical enhancements.

Performance in Moist Environments

Wet strength paper is specifically engineered with synthetic resins that enhance its durability and resistance to tearing when exposed to moisture, outperforming regular strength paper which tends to weaken and disintegrate quickly in wet conditions. This makes wet strength paper ideal for applications such as food packaging, labels, and industrial uses where exposure to moisture is unavoidable. The superior molecular bonding in wet strength paper maintains structural integrity, ensuring consistent performance in challenging humid or wet environments.

Durability and Tear Resistance Compared

Wet strength paper offers significantly enhanced durability and tear resistance compared to regular strength paper, maintaining its integrity when exposed to moisture. The chemical additives in wet strength paper form strong, water-resistant bonds within the fibers, preventing disintegration under wet conditions. Regular strength paper lacks these treatments, resulting in rapid weakening and tearing when wet.

Common Uses of Wet Strength Paper

Wet strength paper is commonly used in applications requiring durability in moist or damp conditions, such as paper towels, labels for beverages, and food packaging. Its enhanced adhesive properties make it ideal for industrial wipes, currency, and outdoor signage, where regular strength paper would deteriorate quickly. The ability to maintain integrity when wet ensures reliability in medical and hygiene products.

Typical Applications for Regular Strength Paper

Regular strength paper is commonly used for everyday printing, writing, and packaging tasks where durability against moisture is not critical. Typical applications include office documents, flyers, newspapers, and standard packaging materials such as grocery bags and wrapping paper. It is ideal for short-term use products that require cost-efficiency and adequate print quality without the need for water resistance.

Environmental Impact: Recyclability and Sustainability

Wet strength paper exhibits enhanced durability and resistance to water, which complicates its recyclability compared to regular strength paper that degrades more easily in recycling processes. The polymers and resins added to wet strength paper, such as polyamide-epichlorohydrin (PAE), reduce fiber recovery rates and increase environmental burdens during recycling. Regular strength paper offers superior sustainability benefits due to its higher recyclability and lower reliance on chemical additives, making it a preferred choice for environmentally conscious applications.

Choosing the Right Paper Material for Your Needs

Wet strength paper contains additives like resin or synthetic polymers that significantly enhance its durability and resistance to water, making it ideal for applications prone to moisture exposure, such as labels, packaging, and outdoor use. Regular strength paper lacks these reinforcements, offering good performance for everyday printing and writing tasks but deteriorates quickly when wet. Selecting the right paper material depends on the specific environmental conditions and functional requirements of your project, ensuring longevity and reliability.

Wet Strength Paper vs Regular Strength Paper Infographic

materialdif.com

materialdif.com