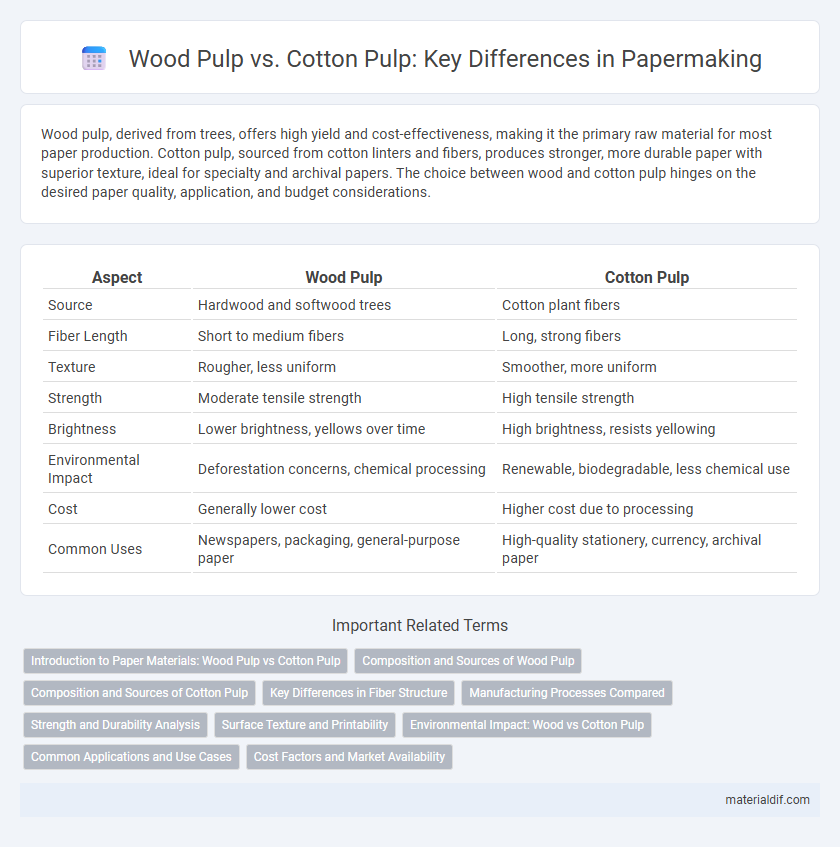

Wood pulp, derived from trees, offers high yield and cost-effectiveness, making it the primary raw material for most paper production. Cotton pulp, sourced from cotton linters and fibers, produces stronger, more durable paper with superior texture, ideal for specialty and archival papers. The choice between wood and cotton pulp hinges on the desired paper quality, application, and budget considerations.

Table of Comparison

| Aspect | Wood Pulp | Cotton Pulp |

|---|---|---|

| Source | Hardwood and softwood trees | Cotton plant fibers |

| Fiber Length | Short to medium fibers | Long, strong fibers |

| Texture | Rougher, less uniform | Smoother, more uniform |

| Strength | Moderate tensile strength | High tensile strength |

| Brightness | Lower brightness, yellows over time | High brightness, resists yellowing |

| Environmental Impact | Deforestation concerns, chemical processing | Renewable, biodegradable, less chemical use |

| Cost | Generally lower cost | Higher cost due to processing |

| Common Uses | Newspapers, packaging, general-purpose paper | High-quality stationery, currency, archival paper |

Introduction to Paper Materials: Wood Pulp vs Cotton Pulp

Wood pulp, derived from softwood and hardwood trees, is the most commonly used raw material in paper production due to its abundant supply and cost-effectiveness, providing fibers that result in sturdy and versatile paper products. Cotton pulp, sourced from cotton linters and rag fibers, offers superior strength, durability, and a smoother texture, often preferred for high-quality stationery, archival papers, and currency. The choice between wood pulp and cotton pulp significantly influences the paper's characteristics, including brightness, longevity, and environmental impact.

Composition and Sources of Wood Pulp

Wood pulp primarily consists of cellulose fibers derived from softwood and hardwood trees, with lignin and hemicellulose as significant components influencing its strength and texture. Common sources of wood pulp include pine, spruce, and fir for softwood, while birch, eucalyptus, and maple represent hardwood varieties. The composition of wood pulp, rich in cellulose and varying lignin content, directly impacts the paper's durability, printability, and environmental footprint compared to cotton pulp, which is almost pure cellulose from cotton linters.

Composition and Sources of Cotton Pulp

Cotton pulp is primarily composed of nearly pure cellulose fibers, which distinguishes it from wood pulp that contains a mix of cellulose, hemicellulose, and lignin. Derived mainly from cotton linters--the short fibers surrounding cotton seeds--cotton pulp offers higher fiber purity and strength compared to wood pulp sourced from softwood and hardwood trees. This purity makes cotton pulp ideal for specialized paper products such as archival and currency papers, where durability and longevity are critical.

Key Differences in Fiber Structure

Wood pulp fibers are shorter and more rigid, providing paper with a rougher texture and increased opacity. Cotton pulp fibers are longer and more flexible, resulting in paper that is softer, stronger, and more durable. The key structural difference lies in cellulose content, with cotton fibers containing higher cellulose purity, which enhances tensile strength and longevity of paper products.

Manufacturing Processes Compared

Wood pulp manufacturing involves mechanically or chemically breaking down wood chips using processes such as kraft or sulfite pulping, resulting in high-yield fiber production suited for mass paper manufacturing. Cotton pulp derives primarily from linters and cotton linters undergo chemical treatments such as soda pulping to isolate cellulose fibers, producing stronger, higher-quality paper ideal for archival and specialty applications. The wood pulp process emphasizes efficiency and volume, whereas cotton pulp focuses on fiber purity and durability, reflecting distinct manufacturing priorities in paper production.

Strength and Durability Analysis

Wood pulp exhibits superior tensile strength due to its long cellulose fibers, making it ideal for applications requiring durability and tear resistance in paper products. Cotton pulp, with its shorter and finer fibers, offers enhanced flexibility and softness but generally lacks the mechanical strength found in wood pulp. The comparative analysis shows wood pulp paper maintains structural integrity under stress, while cotton pulp paper excels in flexibility and longevity against repeated handling.

Surface Texture and Printability

Wood pulp paper typically features a rougher surface texture due to longer and coarser fibers, which can result in less uniform ink absorption during printing. Cotton pulp paper, composed of shorter, finer fibers, offers a smoother and more consistent surface, enhancing print clarity and detail reproduction. This difference in fiber composition significantly impacts the printability, making cotton pulp preferred for high-quality prints requiring sharpness and precision.

Environmental Impact: Wood vs Cotton Pulp

Wood pulp production significantly contributes to deforestation, biodiversity loss, and carbon emissions due to large-scale logging and chemical processing. Cotton pulp, derived from agricultural residues or cotton linters, generally has a lower carbon footprint but requires substantial water and pesticide inputs during cotton cultivation. Sustainable sourcing and recycling practices critically influence the overall environmental impact of both wood and cotton pulp in paper manufacturing.

Common Applications and Use Cases

Wood pulp is widely used in the production of standard printing papers, tissues, and paperboard due to its high cellulose content and cost-effectiveness. Cotton pulp, known for its superior fiber strength and purity, is preferred for archival papers, currency, and high-quality art papers where durability and acid-free properties are essential. Both materials serve distinct sectors, with wood pulp dominating mass-market products and cotton pulp reserved for specialized, long-lasting paper applications.

Cost Factors and Market Availability

Wood pulp is generally more cost-effective than cotton pulp due to its abundant supply and faster production cycle, making it the dominant raw material in the paper industry. Cotton pulp, derived from higher-quality fibers, commands a premium price and is less widely available, limiting its use to specialty and high-end papers. Market availability favors wood pulp as it is produced on a large scale globally, whereas cotton pulp remains niche with limited sourcing regions.

Wood Pulp vs Cotton Pulp Infographic

materialdif.com

materialdif.com