Laid paper features a textured pattern of parallel lines created by a wire sieve during its manufacturing, providing a traditional, handcrafted appearance often used in artistic and archival projects. Wove paper, in contrast, has a smooth, uniform surface resulting from a fine mesh screen, making it ideal for printing and everyday writing purposes. Understanding the distinctive textures and production methods of laid versus wove paper helps in selecting the right paper for specific artistic, archival, or printing needs.

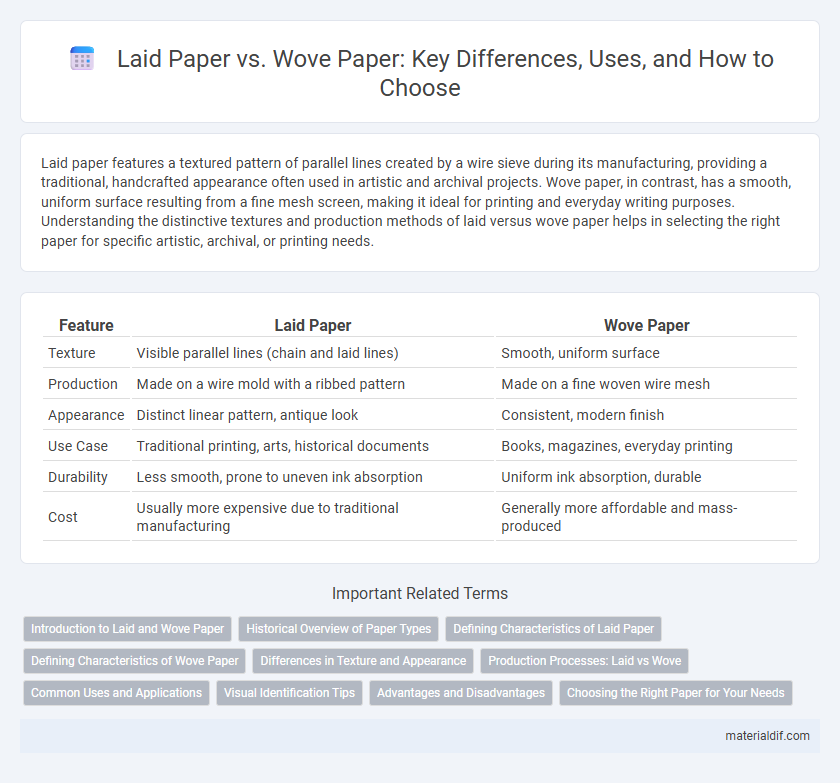

Table of Comparison

| Feature | Laid Paper | Wove Paper |

|---|---|---|

| Texture | Visible parallel lines (chain and laid lines) | Smooth, uniform surface |

| Production | Made on a wire mold with a ribbed pattern | Made on a fine woven wire mesh |

| Appearance | Distinct linear pattern, antique look | Consistent, modern finish |

| Use Case | Traditional printing, arts, historical documents | Books, magazines, everyday printing |

| Durability | Less smooth, prone to uneven ink absorption | Uniform ink absorption, durable |

| Cost | Usually more expensive due to traditional manufacturing | Generally more affordable and mass-produced |

Introduction to Laid and Wove Paper

Laid paper features a textured pattern of parallel lines created by the wire mesh in the papermaking mold, often visible when held up to light, giving it a classic, handmade appearance. Wove paper, on the other hand, has a smooth and uniform surface produced by a tightly woven wire mesh, resulting in an even, consistent texture ideal for printing and writing. Both types differ primarily in their manufacturing process and surface texture, influencing their aesthetic and functional applications.

Historical Overview of Paper Types

Laid paper, characterized by its distinct ribbed texture from wire molds, dates back to medieval Europe and was widely used for manuscripts and official documents. Wove paper, developed in the 18th century by James Whatman, features a smoother surface created with a finer wire mesh, revolutionizing printing and book production. These paper types reflect technological advancements in papermaking that influenced art, writing, and printing history.

Defining Characteristics of Laid Paper

Laid paper is characterized by its distinct textured pattern of parallel lines created by the wire mesh used during its manufacturing process, which contrasts with the smooth surface of wove paper. Its visible ribbed texture provides superior tactile quality and often appears in high-end stationery and historical documents. The presence of chain lines and laid lines arranged perpendicular and parallel adds structural strength and a unique aesthetic signature.

Defining Characteristics of Wove Paper

Wove paper is defined by its smooth, uniform surface created through the use of a fine wire mesh mold, which contrasts with the textured lines of laid paper. This smooth finish makes wove paper ideal for detailed printing, as it does not interfere with ink absorption or image clarity. Commonly used in modern book printing and high-quality artwork, wove paper provides consistent texture and optimal durability.

Differences in Texture and Appearance

Laid paper features a distinct pattern of parallel lines and chain lines, creating a textured surface that is visually apparent and tactilely felt, often used in traditional printmaking and fine art. Wove paper, in contrast, has a uniform, smooth texture without visible lines, resulting from a woven wire mesh mold that produces a consistent appearance ideal for modern printing and writing purposes. The difference in texture between the two types significantly impacts the visual depth and feel, with laid paper offering a classic, handcrafted aesthetic and wove paper providing a sleek, contemporary finish.

Production Processes: Laid vs Wove

Laid paper is produced using a wire mesh mold with closely spaced wires that create characteristic parallel lines and a textured pattern, while wove paper is made with a fine, mesh screen that results in a smooth, uniform surface without visible lines. The laid paper production involves a traditional hand-crafting technique that allows water to drain unevenly through the ribs of the wire, forming its distinctive texture. In contrast, wove paper is typically produced in a more modern, mechanized manner with a continuous, evenly distributed pulp suspension that yields a consistent and even finish.

Common Uses and Applications

Laid paper, characterized by its distinct ribbed texture, is commonly used for fine art prints, historical document reproduction, and high-end stationery due to its classic appearance and tactile quality. Wove paper, with its smooth, uniform surface, dominates in everyday printing, book publishing, and office use because it offers excellent ink absorption and versatility. Both types serve specific applications based on texture requirements and aesthetic preferences in printing and writing projects.

Visual Identification Tips

Laid paper features distinct parallel lines visible when held against light, created by the wire mesh in traditional papermaking, while wove paper displays a uniform, smooth texture without such lines. To visually identify laid paper, look for fine, evenly spaced ribbed patterns running vertically and horizontally, whereas wove paper appears consistent and lacks these grid-like impressions. Checking paper translucency under strong light highlights laid lines sharply, contrasting with the seamless surface of wove paper used in modern printing.

Advantages and Disadvantages

Laid paper features a textured pattern of parallel lines, offering superior ink absorption and an elegant, traditional appearance ideal for fine art and archival documents. Wove paper provides a smooth, even surface that supports detailed printing and modern graphic designs, enhancing clarity and uniformity. Laid paper's texture may hinder high-resolution printing, while wove paper can lack the distinctive tactile quality preferred in heritage or luxury stationery.

Choosing the Right Paper for Your Needs

Laid paper features distinct textured lines created by the wire mesh during production, providing a classic, vintage aesthetic suitable for artistic or formal documents. Wove paper has a smooth, uniform surface ideal for printing and everyday use, offering better ink distribution and clarity. Selecting the right paper depends on the desired visual effect, print quality, and intended purpose of the final product.

Laid Paper vs Wove Paper Infographic

materialdif.com

materialdif.com