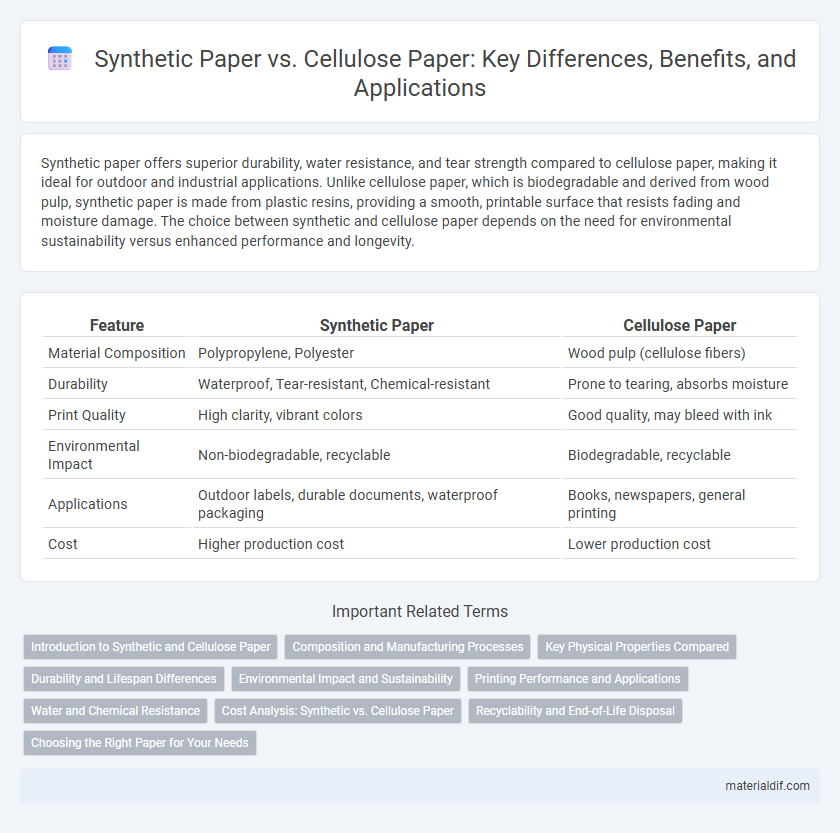

Synthetic paper offers superior durability, water resistance, and tear strength compared to cellulose paper, making it ideal for outdoor and industrial applications. Unlike cellulose paper, which is biodegradable and derived from wood pulp, synthetic paper is made from plastic resins, providing a smooth, printable surface that resists fading and moisture damage. The choice between synthetic and cellulose paper depends on the need for environmental sustainability versus enhanced performance and longevity.

Table of Comparison

| Feature | Synthetic Paper | Cellulose Paper |

|---|---|---|

| Material Composition | Polypropylene, Polyester | Wood pulp (cellulose fibers) |

| Durability | Waterproof, Tear-resistant, Chemical-resistant | Prone to tearing, absorbs moisture |

| Print Quality | High clarity, vibrant colors | Good quality, may bleed with ink |

| Environmental Impact | Non-biodegradable, recyclable | Biodegradable, recyclable |

| Applications | Outdoor labels, durable documents, waterproof packaging | Books, newspapers, general printing |

| Cost | Higher production cost | Lower production cost |

Introduction to Synthetic and Cellulose Paper

Synthetic paper, made from plastic polymers such as polypropylene or polyethylene, offers exceptional durability, water resistance, and tear resistance, making it ideal for applications requiring longevity and environmental exposure. Cellulose paper, derived from natural wood fibers, provides biodegradability, recyclability, and a traditional tactile quality favored in print media and packaging. Understanding the fundamental differences in composition and performance between synthetic and cellulose paper is crucial for selecting the appropriate material for specific industrial, commercial, and creative uses.

Composition and Manufacturing Processes

Synthetic paper is made primarily from polypropylene or polyethylene, offering water resistance and durability, while cellulose paper is derived from natural wood pulp, emphasizing biodegradability and fiber bonding. The manufacturing process of synthetic paper involves extrusion and calendaring to create a smooth, waterproof surface, contrasting with cellulose paper's pulping, pressing, and drying methods that develop its porous texture. Differences in composition and production result in distinct physical properties and usability, with synthetic paper excelling in tear resistance and chemical stability versus the environmental benefits of cellulose paper.

Key Physical Properties Compared

Synthetic paper offers superior tear resistance and water repellency compared to cellulose paper, making it ideal for durable labels and outdoor applications. Its smooth, non-porous surface enhances printability and color vibrancy, while cellulose paper provides better biodegradability and recyclability due to its natural fiber composition. The density of synthetic paper is typically higher, contributing to increased stiffness and longevity under harsh environmental conditions.

Durability and Lifespan Differences

Synthetic paper exhibits superior durability compared to cellulose paper due to its resistance to water, chemicals, and tearing, making it ideal for long-term applications. Unlike cellulose paper, which degrades from moisture and UV exposure, synthetic paper maintains its structural integrity and print quality over extended periods. This enhanced lifespan positions synthetic paper as a cost-effective choice for labels, maps, and outdoor signage requiring prolonged durability.

Environmental Impact and Sustainability

Synthetic paper, made primarily from polypropylene, offers enhanced durability and water resistance compared to cellulose paper derived from wood pulp, reducing waste through longer lifecycle use. Cellulose paper relies on deforestation and intensive water consumption, contributing significantly to environmental degradation and carbon emissions. Sustainable practices favor synthetic paper's recyclability and lower resource dependency, promoting reduced environmental impact and improved conservation of natural forests.

Printing Performance and Applications

Synthetic paper offers superior printing performance compared to cellulose paper due to its smooth, non-porous surface that enables sharper image resolution and vibrant color reproduction. Its resistance to water, chemicals, and tearing makes it ideal for applications such as outdoor signage, labels, and packaging that demand durability and longevity. Cellulose paper, while more eco-friendly and cost-effective, suits traditional printing needs like books and office documents but lacks the durability and moisture resistance of synthetic alternatives.

Water and Chemical Resistance

Synthetic paper exhibits superior water and chemical resistance compared to cellulose paper due to its plastic-based composition, which repels moisture and resists ink smudging or degradation. Cellulose paper, derived from wood fibers, absorbs water easily and is prone to chemical damage, limiting its durability in harsh environments. This resistance makes synthetic paper ideal for applications requiring exposure to liquids or chemicals, such as outdoor labels and industrial uses.

Cost Analysis: Synthetic vs. Cellulose Paper

Synthetic paper typically incurs higher initial production costs than cellulose paper due to advanced manufacturing processes and specialized raw materials. However, its durability, water resistance, and longer lifespan can reduce long-term expenses in applications requiring frequent handling or exposure to harsh environments. Cellulose paper remains more cost-effective for standard printing and packaging needs, benefiting from lower raw material costs and established supply chains.

Recyclability and End-of-Life Disposal

Synthetic paper, made from plastic resins such as polypropylene, offers superior durability and water resistance but poses challenges in recycling due to its polymer composition, often requiring specialized facilities. Cellulose paper, derived from wood pulp, is widely accepted in standard recycling streams and biodegrades naturally, making it more environmentally favorable for end-of-life disposal. The recyclability of cellulose paper contributes to a lower ecological footprint, while synthetic paper's limited recyclability often results in increased landfill accumulation.

Choosing the Right Paper for Your Needs

Synthetic paper offers superior durability, water resistance, and tear resistance compared to cellulose paper, making it ideal for outdoor labels, packaging, and long-lasting documents. Cellulose paper, derived from wood pulp, is biodegradable and cost-effective, preferred for everyday printing, writing, and environmentally conscious applications. Selecting the right paper depends on balancing durability requirements, environmental impact, and budget constraints for your specific project.

Synthetic Paper vs Cellulose Paper Infographic

materialdif.com

materialdif.com