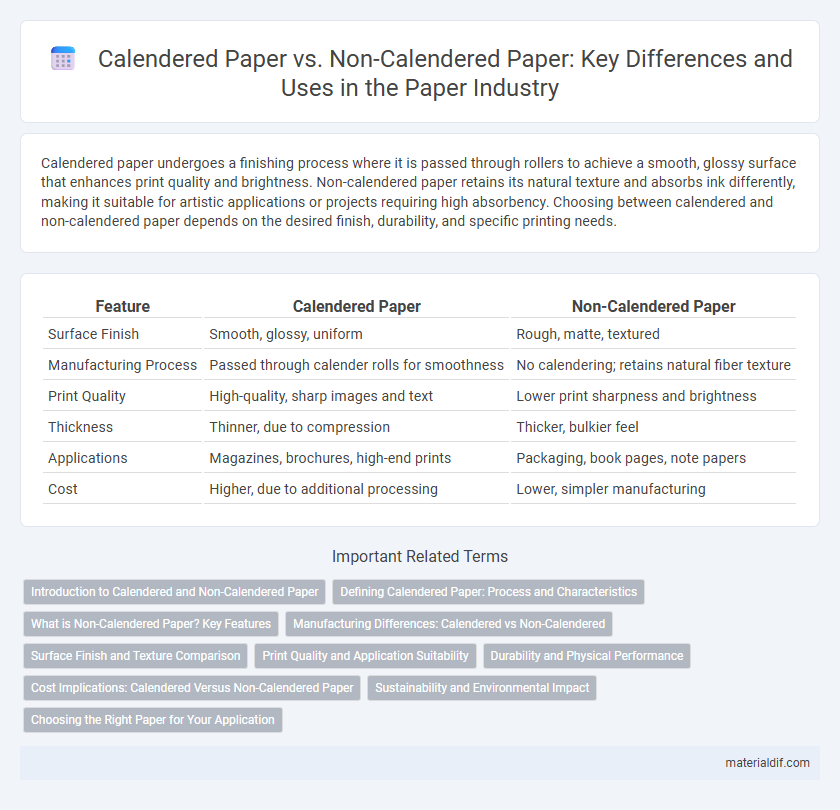

Calendered paper undergoes a finishing process where it is passed through rollers to achieve a smooth, glossy surface that enhances print quality and brightness. Non-calendered paper retains its natural texture and absorbs ink differently, making it suitable for artistic applications or projects requiring high absorbency. Choosing between calendered and non-calendered paper depends on the desired finish, durability, and specific printing needs.

Table of Comparison

| Feature | Calendered Paper | Non-Calendered Paper |

|---|---|---|

| Surface Finish | Smooth, glossy, uniform | Rough, matte, textured |

| Manufacturing Process | Passed through calender rolls for smoothness | No calendering; retains natural fiber texture |

| Print Quality | High-quality, sharp images and text | Lower print sharpness and brightness |

| Thickness | Thinner, due to compression | Thicker, bulkier feel |

| Applications | Magazines, brochures, high-end prints | Packaging, book pages, note papers |

| Cost | Higher, due to additional processing | Lower, simpler manufacturing |

Introduction to Calendered and Non-Calendered Paper

Calendered paper undergoes a finishing process involving smooth rollers that compress the paper fibers to create a glossy, uniform surface ideal for high-quality printing. Non-calendered paper retains a more natural, rough texture without this smoothing treatment, making it suitable for applications requiring better ink absorption and tactile feel. The choice between calendered and non-calendered paper impacts print clarity, surface finish, and ink behavior in various printing and packaging industries.

Defining Calendered Paper: Process and Characteristics

Calendered paper is produced by passing the paper web through a series of heavy rollers called calenders, which compress and smooth the surface to achieve a uniform thickness and glossy finish. This process enhances the paper's density, surface strength, and printability, making it ideal for high-quality printing applications such as magazines and brochures. The primary characteristics of calendered paper include improved brightness, reduced porosity, and a smooth texture that supports sharp image reproduction.

What is Non-Calendered Paper? Key Features

Non-calendered paper is a type of paper that has not undergone the calendering process, resulting in a rougher surface texture and increased bulk. This paper retains higher porosity, making it ideal for applications requiring ink absorption and enhanced printability, such as packaging and certain printing tasks. Key features include superior opacity, better grip, and enhanced absorption properties compared to calendered paper.

Manufacturing Differences: Calendered vs Non-Calendered

Calendered paper undergoes a manufacturing process where it passes through heated rollers to achieve a smooth, glossy surface and uniform thickness, enhancing its print quality and durability. In contrast, non-calendered paper skips this process, resulting in a rougher texture with higher absorbency and a more natural feel, often used for packaging and artistic applications. The calendering stage significantly influences the paper's density, surface smoothness, and weight, making calendered paper ideal for high-end printing while non-calendered paper offers better ink absorption and bulk.

Surface Finish and Texture Comparison

Calendered paper undergoes a smoothing process through rollers that compress and polish the surface, resulting in a glossy, uniform finish ideal for high-quality printing and sharp image reproduction. Non-calendered paper retains its natural texture and roughness, providing a matte surface with higher absorbency, often preferred for artistic and textured printing applications. The surface finish of calendered paper enhances print clarity and color vibrancy, while non-calendered paper offers a tactile feel and better ink adhesion for specialty prints.

Print Quality and Application Suitability

Calendered paper undergoes a finishing process that smooths its surface, enhancing print quality by providing sharper images and vibrant colors, making it ideal for high-quality brochures and magazines. Non-calendered paper retains a more textured surface, which can absorb ink more readily and is better suited for applications like printing books or packaging where a matte finish and durability are preferred. The choice between calendered and non-calendered paper directly impacts the visual appeal and functional performance depending on the specific printing requirements.

Durability and Physical Performance

Calendered paper exhibits enhanced smoothness and glossiness due to compression during production, which improves its physical durability by increasing resistance to wear, tear, and moisture. Non-calendered paper retains a rougher texture, resulting in higher absorbency but lower structural strength and reduced resistance to mechanical stress. The choice between calendered and non-calendered paper impacts longevity and performance depending on application requirements for abrasion resistance and print quality.

Cost Implications: Calendered Versus Non-Calendered Paper

Calendered paper undergoes a smoothing process using rollers, resulting in a glossy finish that typically increases production costs compared to non-calendered paper. Non-calendered paper, with its rougher texture and absence of finishing treatments, offers a more economical choice suitable for applications where surface smoothness is less critical. The cost implications favor non-calendered paper for budget-sensitive projects, while calendered paper justifies higher expenses through enhanced print quality and appearance.

Sustainability and Environmental Impact

Calendered paper undergoes a smoothing process that improves print quality but often consumes more energy and chemicals, impacting environmental sustainability. Non-calendered paper, while rougher, typically involves fewer processing steps, reducing its carbon footprint and resource use. Choosing non-calendered paper supports eco-friendly practices by minimizing energy consumption and chemical waste in production.

Choosing the Right Paper for Your Application

Calendered paper features a smooth, glossy finish achieved by passing the paper through heated rollers, making it ideal for high-quality printing and packaging applications that demand sharp images and vibrant colors. Non-calendered paper retains a rougher texture and higher absorbency, which suits printing processes requiring better ink adhesion and tactile qualities, such as artistic prints or labels. Selecting between calendered and non-calendered paper depends on the specific application's need for surface finish, print quality, and durability requirements.

Calendered paper vs Non-calendered paper Infographic

materialdif.com

materialdif.com