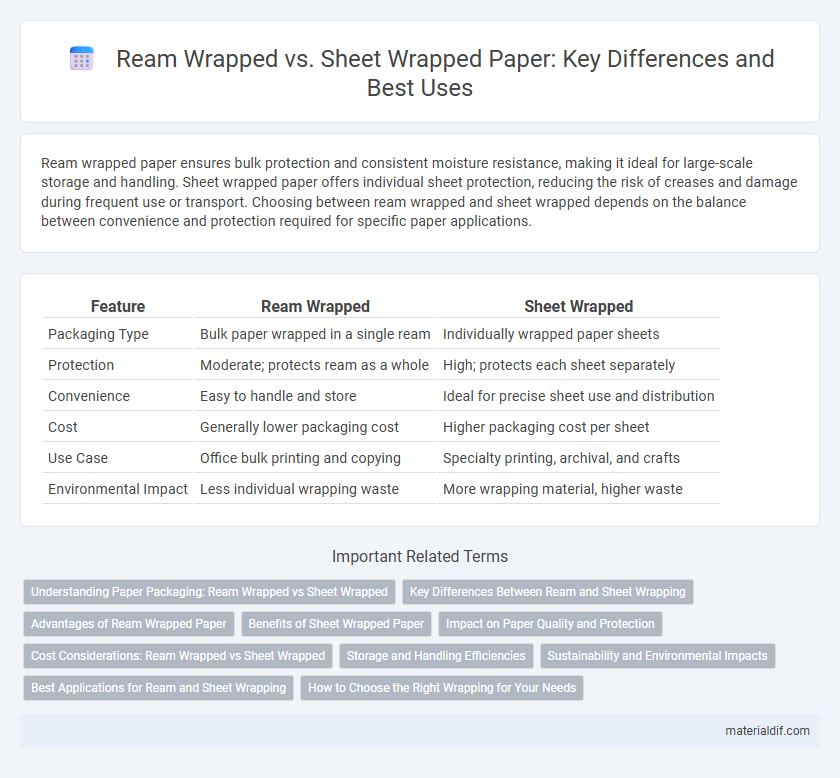

Ream wrapped paper ensures bulk protection and consistent moisture resistance, making it ideal for large-scale storage and handling. Sheet wrapped paper offers individual sheet protection, reducing the risk of creases and damage during frequent use or transport. Choosing between ream wrapped and sheet wrapped depends on the balance between convenience and protection required for specific paper applications.

Table of Comparison

| Feature | Ream Wrapped | Sheet Wrapped |

|---|---|---|

| Packaging Type | Bulk paper wrapped in a single ream | Individually wrapped paper sheets |

| Protection | Moderate; protects ream as a whole | High; protects each sheet separately |

| Convenience | Easy to handle and store | Ideal for precise sheet use and distribution |

| Cost | Generally lower packaging cost | Higher packaging cost per sheet |

| Use Case | Office bulk printing and copying | Specialty printing, archival, and crafts |

| Environmental Impact | Less individual wrapping waste | More wrapping material, higher waste |

Understanding Paper Packaging: Ream Wrapped vs Sheet Wrapped

Ream wrapped paper is packaged in a single bundle typically containing 500 sheets, offering better protection from moisture and damage during storage and transportation. Sheet wrapped paper is individually wrapped sheets, providing convenience for immediate use and reducing the risk of handling multiple sheets at once. Choosing between ream wrapped and sheet wrapped paper depends on the need for bulk protection versus ease of use and accessibility in printing or copying tasks.

Key Differences Between Ream and Sheet Wrapping

Ream wrapping involves packaging a fixed quantity of paper sheets, typically 500, bound together as a single unit, while sheet wrapping encloses individual sheets or smaller subsets. Ream-wrapped paper offers uniform protection and bulk handling efficiency, whereas sheet wrapping provides flexibility and easier access for individual sheets. Key differences include packaging scale, protection level, and usage convenience tailored to varying printing and office requirements.

Advantages of Ream Wrapped Paper

Ream wrapped paper offers superior protection from moisture and contaminants, ensuring consistent sheet quality and preventing damage during storage and transport. The individual wrapping of 500 sheets enhances handling convenience and reduces paper waste by maintaining the integrity of unused portions. This method supports better inventory management and reduces the risk of paper curling or sticking, making it ideal for high-quality printing and professional use.

Benefits of Sheet Wrapped Paper

Sheet wrapped paper offers enhanced protection against moisture and dirt, preserving paper quality during storage and transportation. Individual sheets reduce handling damage, improving overall usability and print consistency. This packaging method also facilitates easier inventory management and quicker access for high-volume print jobs.

Impact on Paper Quality and Protection

Ream wrapped paper provides consistent protection against moisture, dust, and other contaminants, preserving the integrity and smoothness of the sheets within the package. Sheet wrapping, while offering greater visibility and easier handling of individual sheets, can expose paper to environmental factors, potentially leading to uneven wear or surface damage. Choosing between ream wrapping and sheet wrapping significantly impacts paper quality maintenance, especially in storage or high-humidity conditions.

Cost Considerations: Ream Wrapped vs Sheet Wrapped

Ream wrapped paper offers lower packaging costs due to bulk packaging efficiency, reducing material and labor expenses compared to sheet wrapped paper, which requires more individual wrapping and labor-intensive handling. Sheet wrapped paper incurs higher costs from increased packaging materials, additional labor for wrapping each sheet, and greater storage space requirements. Businesses evaluating cost considerations should balance the upfront savings of ream wrapped paper against the convenience and protection provided by sheet wrapped options.

Storage and Handling Efficiencies

Ream wrapped paper offers enhanced protection against moisture and dust, making it ideal for long-term storage environments with fluctuating humidity levels. Sheet wrapped paper allows for quicker access and easier handling in high-turnover situations, reducing labor time during inventory management. Choosing between the two depends on balancing storage conditions and operational efficiency in paper handling workflows.

Sustainability and Environmental Impacts

Ream wrapped paper typically uses a single layer of recyclable paper wrapping, reducing overall packaging waste compared to sheet wrapped paper, which often involves multiple plastic sleeves per bundle. The production and disposal of sheet wrapping contribute to increased plastic pollution and longer degradation times, negatively impacting ecosystems. Choosing ream wrapped paper supports sustainable practices by minimizing plastic use and enhancing recyclability in office and printing environments.

Best Applications for Ream and Sheet Wrapping

Ream wrapped paper is best suited for bulk storage and transport, providing protection from dust and moisture while maintaining the integrity of large quantities of sheets. Sheet wrapped paper is ideal for smaller, individual stacks, offering easy access and reducing waste by allowing users to peel off only the required amount. Choosing between ream and sheet wrapping depends on the scale of use and the need for convenience versus long-term preservation.

How to Choose the Right Wrapping for Your Needs

Choosing between ream wrapped and sheet wrapped paper depends on your storage and usage requirements. Ream wrapped paper offers bulk protection and is ideal for high-volume printing, while sheet wrapped paper provides individual sheet protection, perfect for specialty or colored papers. Consider factors like moisture protection, ease of access, and presentation to select the wrapping that best preserves paper quality and suits your operational needs.

Ream Wrapped vs Sheet Wrapped Infographic

materialdif.com

materialdif.com