Machine-finished paper offers a smoother, more uniform surface achieved through automated processes, providing consistent quality and high production efficiency. Hand-finished paper, on the other hand, delivers a unique texture and artisanal feel, often preferred for specialty applications requiring a distinct tactile experience. Choosing between machine-finished and hand-finished paper depends on the desired aesthetic, texture, and use case in printing or crafting projects.

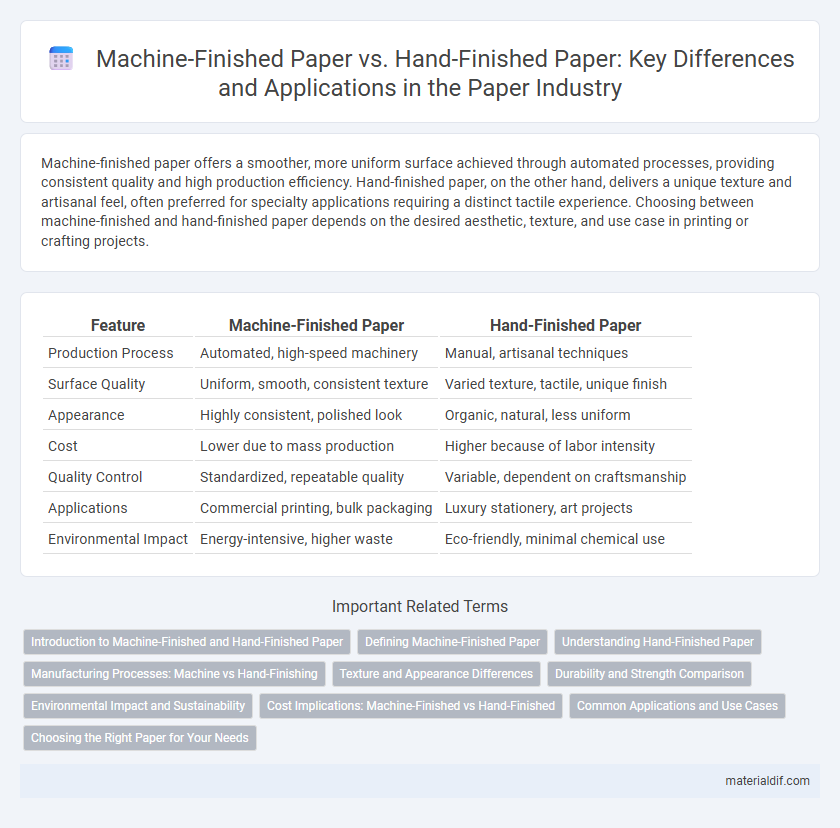

Table of Comparison

| Feature | Machine-Finished Paper | Hand-Finished Paper |

|---|---|---|

| Production Process | Automated, high-speed machinery | Manual, artisanal techniques |

| Surface Quality | Uniform, smooth, consistent texture | Varied texture, tactile, unique finish |

| Appearance | Highly consistent, polished look | Organic, natural, less uniform |

| Cost | Lower due to mass production | Higher because of labor intensity |

| Quality Control | Standardized, repeatable quality | Variable, dependent on craftsmanship |

| Applications | Commercial printing, bulk packaging | Luxury stationery, art projects |

| Environmental Impact | Energy-intensive, higher waste | Eco-friendly, minimal chemical use |

Introduction to Machine-Finished and Hand-Finished Paper

Machine-finished paper is produced using automated machinery that ensures consistent thickness, smooth surfaces, and uniform texture, ideal for high-volume printing. Hand-finished paper involves manual processes such as surface sizing, calendaring, and texturing, providing unique tactile qualities and artisanal appeal. Differences in finish influence printability, durability, and aesthetic outcomes, making the choice dependent on specific project requirements.

Defining Machine-Finished Paper

Machine-finished paper is produced using automated processes that ensure consistent texture, gloss, and smoothness through mechanical calendaring. This type of paper often features uniform surface properties ideal for high-volume printing and packaging applications. Its precise finish enhances print quality and durability, distinguishing it from the variable, artisanal qualities of hand-finished paper.

Understanding Hand-Finished Paper

Hand-finished paper involves manual techniques like embossing, embossing, and deckling that create unique textures and edges, enhancing aesthetic appeal and tactile quality compared to uniform machine-finished paper. Artisans use tools such as knives and brushes to shape and surface-treat the paper, resulting in one-of-a-kind sheets often favored for high-end stationery and art projects. The subtle variations in thickness, fiber distribution, and surface finish contribute to the distinctive character and durability of hand-finished paper.

Manufacturing Processes: Machine vs Hand-Finishing

Machine-finished paper undergoes a high-speed calendaring process where rollers press the paper to achieve uniform smoothness and gloss, optimizing consistency and production efficiency. In contrast, hand-finished paper involves manual techniques such as hand-calendering or embossing, allowing for unique textures and artisanal detailing but resulting in longer production times. The manufacturing process directly impacts paper quality, surface characteristics, and suitability for specialized artistic or commercial applications.

Texture and Appearance Differences

Machine-finished paper features a smooth, uniform texture due to continuous processing on calender rollers, resulting in a consistent shine and even surface ideal for high-volume printing. Hand-finished paper exhibits a more textured and varied surface, with subtle irregularities and a natural matte finish that enhances its tactile appeal and artisanal quality. These differences in texture and appearance affect the paper's suitability for different printing techniques and aesthetic preferences.

Durability and Strength Comparison

Machine-finished paper typically offers greater consistency in durability and strength due to precise manufacturing controls, resulting in uniform fiber distribution and higher tensile strength. Hand-finished paper often exhibits unique textures but may have variable thickness and weaker fiber bonding, which can compromise longevity under stress. Industrial-grade machine finishing produces papers better suited for demanding applications requiring resilience and tear resistance.

Environmental Impact and Sustainability

Machine-finished paper typically requires large-scale industrial processes that consume significant energy and water, leading to a higher carbon footprint compared to hand-finished paper. Hand-finished paper production often utilizes traditional, less mechanized methods, resulting in reduced resource usage and lower environmental pollution. Sustainable paper practices emphasize adopting hand-finishing techniques to minimize energy consumption and support eco-friendly production cycles.

Cost Implications: Machine-Finished vs Hand-Finished

Machine-finished paper typically incurs lower production costs due to automated processes, resulting in more affordable pricing for bulk orders. Hand-finished paper demands higher labor inputs and time investment, significantly increasing its cost and making it a premium option for specialty applications. Businesses must balance budget constraints with quality requirements when choosing between these two paper types.

Common Applications and Use Cases

Machine-finished paper is widely used in mass production for printing books, magazines, and newspapers due to its uniform texture and cost efficiency. Hand-finished paper is preferred for high-quality art prints, custom stationery, and luxury packaging where unique texture and craftsmanship add value. Both types serve distinct purposes in publishing, commercial printing, and fine arts based on production scale and finish quality.

Choosing the Right Paper for Your Needs

Machine-finished paper offers consistent texture and uniform thickness, ideal for bulk printing and professional documents requiring smooth finishes. Hand-finished paper provides unique textures and artisanal appeal, perfect for luxury stationery, invitations, or artistic projects demanding a personalized touch. Selecting the right paper depends on the intended use, desired aesthetic, and budget, balancing between efficiency and craftsmanship.

Machine-Finished Paper vs Hand-Finished Paper Infographic

materialdif.com

materialdif.com