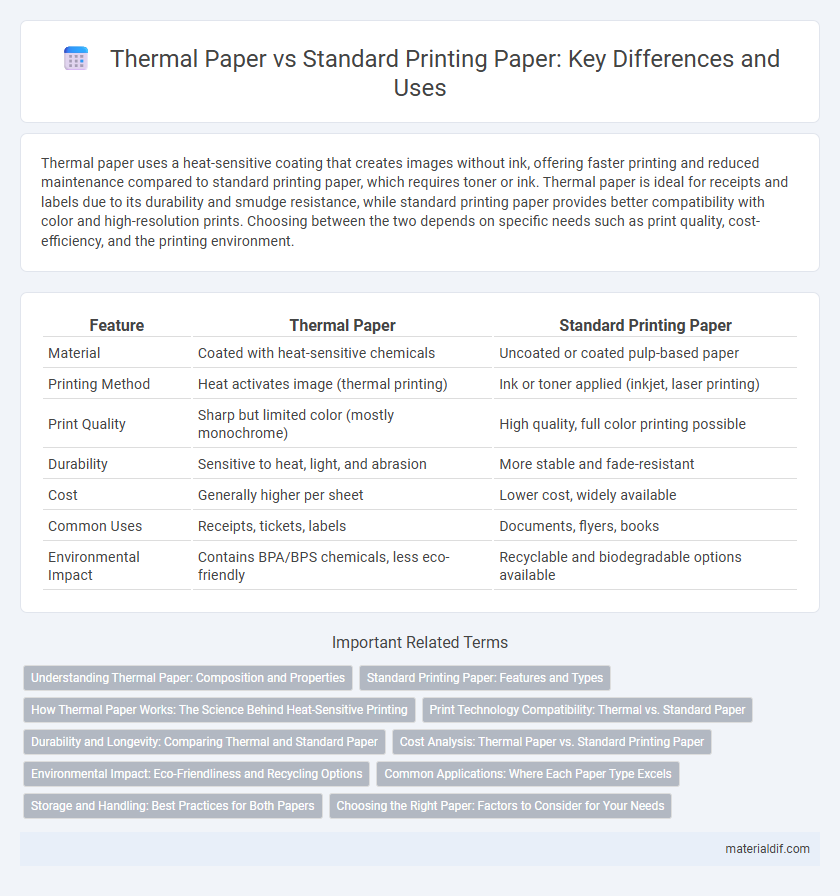

Thermal paper uses a heat-sensitive coating that creates images without ink, offering faster printing and reduced maintenance compared to standard printing paper, which requires toner or ink. Thermal paper is ideal for receipts and labels due to its durability and smudge resistance, while standard printing paper provides better compatibility with color and high-resolution prints. Choosing between the two depends on specific needs such as print quality, cost-efficiency, and the printing environment.

Table of Comparison

| Feature | Thermal Paper | Standard Printing Paper |

|---|---|---|

| Material | Coated with heat-sensitive chemicals | Uncoated or coated pulp-based paper |

| Printing Method | Heat activates image (thermal printing) | Ink or toner applied (inkjet, laser printing) |

| Print Quality | Sharp but limited color (mostly monochrome) | High quality, full color printing possible |

| Durability | Sensitive to heat, light, and abrasion | More stable and fade-resistant |

| Cost | Generally higher per sheet | Lower cost, widely available |

| Common Uses | Receipts, tickets, labels | Documents, flyers, books |

| Environmental Impact | Contains BPA/BPS chemicals, less eco-friendly | Recyclable and biodegradable options available |

Understanding Thermal Paper: Composition and Properties

Thermal paper is coated with a special heat-sensitive layer that changes color when exposed to heat, eliminating the need for ink or toner in printing. This coating typically consists of a dye, developer, and stabilizer, enabling high-resolution, fast, and quiet printing ideal for receipts and labels. Unlike standard printing paper, which relies on inks or toners for image formation, thermal paper's unique composition offers durability against smudging and fading under normal conditions but can be sensitive to heat and light exposure.

Standard Printing Paper: Features and Types

Standard printing paper features a versatile composition primarily made from wood pulp, offering durability and a smooth surface ideal for ink absorption in various printing processes. This paper type includes several varieties such as bond, offset, and coated paper, each designed to suit specific printing needs from everyday office use to high-quality graphic prints. Its compatibility with inkjet, laser, and offset printers makes standard printing paper a staple choice for documents, marketing materials, and books requiring long-lasting readability and print clarity.

How Thermal Paper Works: The Science Behind Heat-Sensitive Printing

Thermal paper is coated with a special heat-sensitive layer containing dye and developer chemicals that react when exposed to heat, producing an image without the use of ink. When the thermal print head heats specific areas of the paper, the dye undergoes a chemical reaction, turning black or changing color to form text or images instantly. This process enables fast, quiet, and efficient printing, commonly used in receipts, labels, and tickets.

Print Technology Compatibility: Thermal vs. Standard Paper

Thermal paper is designed for use with thermal printers that utilize heat-sensitive coatings to produce images, while standard printing paper is compatible with inkjet and laser printers that require ink or toner application. Thermal paper does not work with ink-based printers, as it relies on direct heat to create print, making it ideal for receipts, labels, and tickets. Standard printing paper supports a broader range of printing technologies but lacks the specialized heat-sensitive properties essential for thermal printing processes.

Durability and Longevity: Comparing Thermal and Standard Paper

Thermal paper features a heat-sensitive coating that gradually fades or darkens over time, limiting its durability and longevity compared to standard printing paper. Standard printing paper, composed of cellulose fibers and often treated for archival quality, offers superior resistance to environmental factors like light, humidity, and abrasion, making it more suitable for long-term documentation. For applications requiring extended lifespan and durability, standard printing paper is the preferred choice over thermal paper.

Cost Analysis: Thermal Paper vs. Standard Printing Paper

Thermal paper generally incurs higher initial costs compared to standard printing paper due to specialized coating and manufacturing processes, but it eliminates the need for ink or toner, reducing ongoing expenses. Standard printing paper requires continuous investment in ink cartridges or toner, which can escalate total operating costs over time despite its lower purchase price. Evaluating total cost of ownership must consider both upfront material costs and consumable expenses to determine the most cost-effective option for printing needs.

Environmental Impact: Eco-Friendliness and Recycling Options

Thermal paper production often involves chemical coatings like BPA or BPS, raising environmental concerns due to potential toxicity and limited recyclability compared to standard printing paper, which is generally easier to recycle and biodegradable. Standard printing paper, especially when sourced from sustainably managed forests or made from recycled materials, offers a more eco-friendly option that reduces deforestation and landfill waste. Recycling programs frequently accept standard printing paper, whereas thermal paper recycling is restricted or discouraged because of the hazardous chemicals in its coating.

Common Applications: Where Each Paper Type Excels

Thermal paper excels in point-of-sale receipts, shipping labels, and medical records due to its heat-sensitive coating that enables fast, quiet printing without ink. Standard printing paper is ideal for everyday office use, documents, and high-resolution color printing because of its compatibility with various ink types and printers. Choosing between these papers depends on the need for durability, print speed, and printing technology.

Storage and Handling: Best Practices for Both Papers

Thermal paper requires storage in a cool, dry environment away from direct sunlight and high humidity to prevent fading and discoloration, unlike standard printing paper, which is more resistant but still benefits from similar conditions. Proper handling of thermal paper involves minimizing contact with oils and dirt to preserve image quality, whereas standard paper demands protection from moisture to avoid warping or damage. Both papers should be stored flat, preferably in original packaging, to ensure longevity and optimal performance during printing tasks.

Choosing the Right Paper: Factors to Consider for Your Needs

Thermal paper offers faster printing speeds and requires no ink, making it ideal for receipts and labels where quick, cost-effective output is needed. Standard printing paper provides higher durability and compatibility with various printing methods, suitable for documents requiring longevity and color printing. Consider factors such as print quality, durability, cost, and the specific printer type to select the best paper that matches your printing requirements and budget.

Thermal Paper vs Standard Printing Paper Infographic

materialdif.com

materialdif.com