SBS (Solid Bleached Sulfate) paper offers a premium white, smooth surface ideal for high-quality printing and packaging, while FBB (Folding Box Board) provides a lightweight, rigid structure with excellent stiffness for durable boxes. SBS is preferred for luxury packaging due to its purity and superior printing fidelity, whereas FBB balances strength and cost-effectiveness for everyday packaging needs. Both papers support sustainable forestry practices but differ significantly in texture, weight, and application.

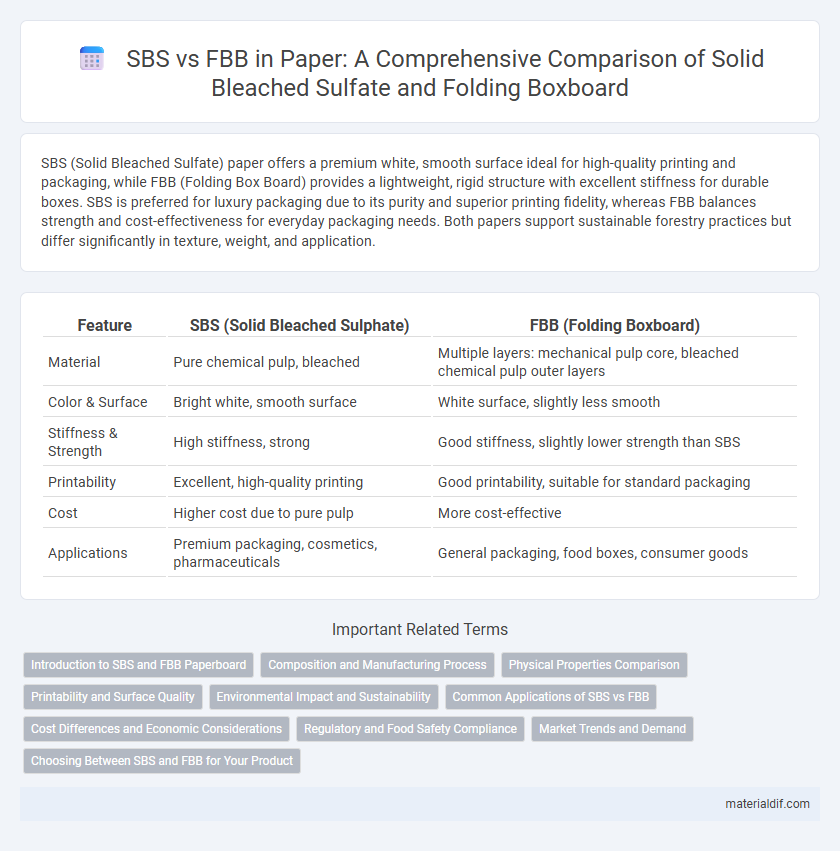

Table of Comparison

| Feature | SBS (Solid Bleached Sulphate) | FBB (Folding Boxboard) |

|---|---|---|

| Material | Pure chemical pulp, bleached | Multiple layers: mechanical pulp core, bleached chemical pulp outer layers |

| Color & Surface | Bright white, smooth surface | White surface, slightly less smooth |

| Stiffness & Strength | High stiffness, strong | Good stiffness, slightly lower strength than SBS |

| Printability | Excellent, high-quality printing | Good printability, suitable for standard packaging |

| Cost | Higher cost due to pure pulp | More cost-effective |

| Applications | Premium packaging, cosmetics, pharmaceuticals | General packaging, food boxes, consumer goods |

Introduction to SBS and FBB Paperboard

SBS (Solid Bleached Sulfate) paperboard features a fully bleached virgin fiber composition, providing a clean, white surface ideal for high-end packaging and printing. FBB (Folding Boxboard) combines mechanical and chemical pulp layers with a bleached chemical pulp top layer, offering excellent stiffness and printability at a lower cost. Both SBS and FBB serve distinct market demands, with SBS excelling in premium cosmetic and food packaging, while FBB is widely used in consumer goods cartons due to its versatility and sustainability.

Composition and Manufacturing Process

SBS (Solid Bleached Sulfate) paper features a pure chemical pulp composition, ensuring a clean, white surface ideal for premium printing, while FBB (Folding Box Board) combines multiple layers, including mechanical pulp, enhancing stiffness and bulk. Manufacturing of SBS involves a fully bleached kraft process with minimal fillers to maintain brightness and strength, whereas FBB production incorporates a multilayer structure with top layers of bleached chemical pulp and inner layers of mechanical pulp to optimize rigidity and cost efficiency. The distinct pulp composition and layering techniques in SBS and FBB directly influence their printing quality, durability, and suitability for packaging applications.

Physical Properties Comparison

SBS (Styrene-Butadiene-Styrene) exhibits superior elasticity and tensile strength compared to FBB (Folding Boxboard), which offers higher stiffness and better surface smoothness ideal for printing applications. The elastic modulus of SBS ranges between 15-25 MPa, while FBB typically demonstrates a modulus of 2000-3000 MPa, highlighting its rigid structure. Moisture resistance is generally better in SBS due to its synthetic polymer composition, whereas FBB's cellulose fibers contribute to higher absorbency and environmental biodegradability.

Printability and Surface Quality

SBS (Solid Bleached Sulfate) offers superior printability due to its smooth, bright surface that enhances ink adhesion and color vibrancy, making it ideal for high-quality graphics and detailed designs. In contrast, FBB (Folding Box Board) features a multi-ply structure with a natural fiber texture that can affect surface uniformity, potentially reducing print sharpness and color consistency. Surface quality in SBS is consistently premium, with a uniform, glossy finish, while FBB's varied texture may require additional coating to achieve comparable smoothness and print quality.

Environmental Impact and Sustainability

SBS (Solid Bleached Sulfate) paper, derived from virgin fibers, generally exhibits higher environmental impacts due to intensive resource use and energy consumption, whereas FBB (Folding Boxboard) often incorporates recycled fibers, reducing its ecological footprint. FBB's sustainability is enhanced by lower greenhouse gas emissions and less water pollution during production, making it a preferable choice for eco-conscious packaging. The choice between SBS and FBB significantly influences the overall environmental performance and circularity in paper-based products.

Common Applications of SBS vs FBB

SBS (Solid Bleached Sulfate) paper is commonly used for high-quality printing applications such as packaging, food containers, and luxury product labels due to its smooth, clean surface and excellent printability. FBB (Folding Box Board) is widely utilized in the production of cartons, cosmetic packaging, pharmaceuticals, and confectionery boxes, offering strength and lightweight properties suitable for folding and cutting processes. Both SBS and FBB serve distinct roles in packaging industries where product protection and visual appeal are critical.

Cost Differences and Economic Considerations

SBS (Solid Bleached Sulfate) paper typically incurs higher production costs compared to FBB (Folding Box Board) due to its refined pulp and bleaching processes, making it more expensive for premium packaging. FBB offers a cost-effective alternative, balancing strength and printability while reducing raw material expenses, which appeals to budget-sensitive packaging solutions. Economic considerations often favor FBB for large-scale, cost-conscious projects, whereas SBS is chosen for premium branding where visual appeal justifies the price premium.

Regulatory and Food Safety Compliance

Styrene-Butadiene-Styrene (SBS) and Folding Boxboard (FBB) differ significantly in regulatory and food safety compliance standards, with FBB often preferred for direct food contact due to its superior barrier properties and compliance with FDA and EFSA regulations. SBS, a synthetic polymer, poses challenges regarding migration limits and may require additional coatings or treatments to meet stringent food safety standards. Ensuring compliance involves rigorous testing for contaminants, migration rates, and certification under relevant food packaging directives to guarantee consumer safety and regulatory approval.

Market Trends and Demand

SBS (Styrene-Butadiene-Styrene) paper is gaining traction in packaging markets due to its enhanced durability and water resistance compared to FBB (Folding Box Board). Market demand shifts toward SBS are driven by sustainability trends as SBS papers often incorporate recyclable and biodegradable components, appealing to eco-conscious consumers. FBB remains popular for high-quality printing and luxury packaging, but growth rates are slower compared to the rising adoption of SBS in flexible packaging and food service sectors.

Choosing Between SBS and FBB for Your Product

Selecting between SBS (Solid Bleached Sulfate) and FBB (Folding Boxboard) depends on the product's requirements for strength, printability, and sustainability. SBS offers superior whiteness and surface smoothness, making it ideal for high-end packaging that demands excellent graphic presentation and food safety compliance. FBB provides a cost-effective alternative with good stiffness and print quality, suitable for general consumer goods where durability and eco-friendliness are key considerations.

SBS vs FBB Infographic

materialdif.com

materialdif.com