Wet-strength paper maintains its structural integrity and durability when exposed to moisture, making it ideal for applications like labels, packaging, and tissues that require water resistance. Regular paper, however, loses strength and becomes fragile once wet, limiting its use to dry environments such as writing, printing, and general office tasks. The chemical additives in wet-strength paper create permanent bonds within the fibers, enhancing performance in humid or wet conditions without compromising recyclability.

Table of Comparison

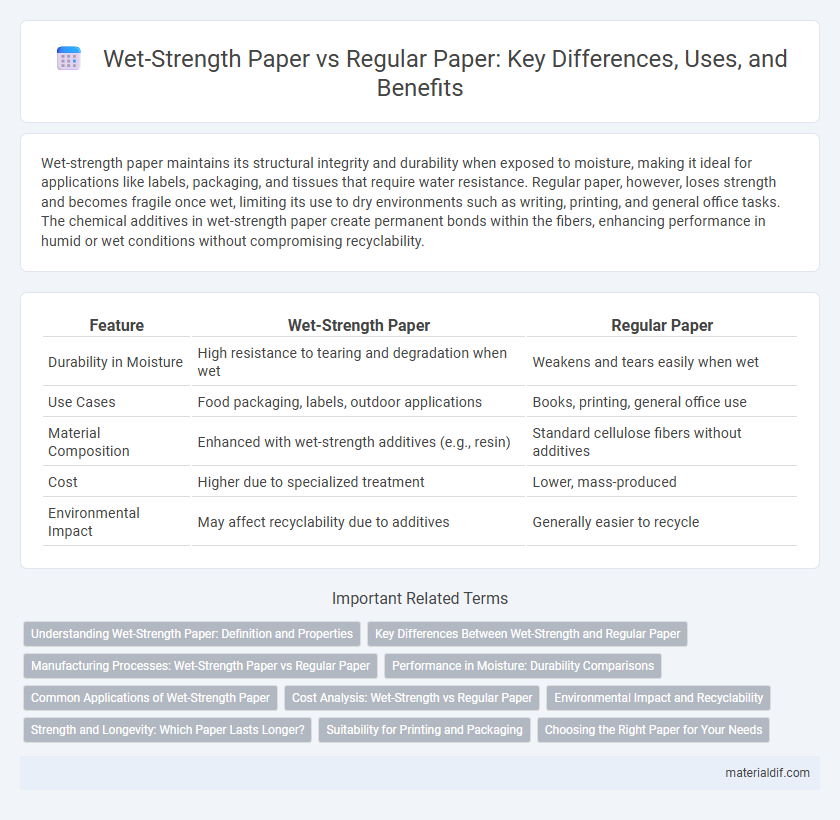

| Feature | Wet-Strength Paper | Regular Paper |

|---|---|---|

| Durability in Moisture | High resistance to tearing and degradation when wet | Weakens and tears easily when wet |

| Use Cases | Food packaging, labels, outdoor applications | Books, printing, general office use |

| Material Composition | Enhanced with wet-strength additives (e.g., resin) | Standard cellulose fibers without additives |

| Cost | Higher due to specialized treatment | Lower, mass-produced |

| Environmental Impact | May affect recyclability due to additives | Generally easier to recycle |

Understanding Wet-Strength Paper: Definition and Properties

Wet-strength paper contains specialized resins that enhance its durability and resistance to moisture, preventing disintegration when exposed to water. These papers maintain structural integrity due to the chemical bonding of wet-strength agents, making them ideal for packaging, labels, and tissues that require water resistance. In contrast, regular paper lacks these additives and weakens significantly when wet, limiting its use in damp environments.

Key Differences Between Wet-Strength and Regular Paper

Wet-strength paper features enhanced durability and resistance to water due to the incorporation of wet-strength resins, making it ideal for packaging, labels, and applications exposed to moisture. Regular paper lacks these resins, resulting in reduced tensile strength and integrity when wet, which limits its use primarily to dry conditions such as printing and writing. The key difference lies in how wet-strength paper maintains structural stability and prevents fiber swelling upon exposure to water, whereas regular paper disintegrates or weakens significantly.

Manufacturing Processes: Wet-Strength Paper vs Regular Paper

Wet-strength paper manufacturing incorporates chemical additives such as polyamide-epichlorohydrin (PAE) resins during the refining process to enhance fiber bonding and water resistance, unlike regular paper which relies primarily on mechanical fiber entanglement and hydrogen bonding. The addition of wet-strength agents occurs before sheet formation, ensuring durability and integrity when exposed to moisture. Regular paper production typically involves less complex pulping and pressing methods, resulting in reduced resistance to wet conditions.

Performance in Moisture: Durability Comparisons

Wet-strength paper maintains its structural integrity and resists disintegration when exposed to moisture, outperforming regular paper that weakens and tears easily under wet conditions. The presence of wet-strength resins in the manufacturing process significantly enhances the paper's durability, allowing it to retain tensile strength even after prolonged contact with water. Regular paper's cellulose fibers swell and lose bonding when wet, leading to rapid degradation, while wet-strength paper ensures reliability in environments with high humidity or direct water exposure.

Common Applications of Wet-Strength Paper

Wet-strength paper is commonly used in packaging, labels, and food service products where moisture resistance is crucial, such as paper cups, paper towels, and grocery bags. It is essential in industrial applications like filter papers and shipping bags that require durability under damp conditions. This type of paper maintains integrity and strength after exposure to water, making it ideal for outdoor and hygienic uses.

Cost Analysis: Wet-Strength vs Regular Paper

Wet-strength paper incurs higher production costs due to specialized resins and enhanced manufacturing processes that improve durability in moist conditions. Regular paper remains more cost-effective because it lacks these additives, making it suitable for dry environments and lower-budget applications. Businesses must balance the increased expense of wet-strength paper against its extended lifespan and reduced product damage in humid or wet settings.

Environmental Impact and Recyclability

Wet-strength paper contains chemical additives that make it resistant to water damage, which complicates the recycling process and increases environmental impact compared to regular paper. Regular paper, being more biodegradable and easier to recycle, results in lower landfill waste and reduced energy consumption during recycling. The environmental footprint of wet-strength paper is higher due to persistent chemicals that hinder fiber recovery and contribute to pollution.

Strength and Longevity: Which Paper Lasts Longer?

Wet-strength paper incorporates chemical additives like wet-strength resins that enhance fiber bonding, providing superior durability and resistance to tearing when exposed to moisture compared to regular paper. This enhanced strength allows wet-strength paper to maintain structural integrity and usability far longer under wet conditions, making it ideal for applications requiring longevity and moisture resistance. Regular paper, lacking these additives, deteriorates quickly upon contact with water, significantly reducing its lifespan and mechanical strength.

Suitability for Printing and Packaging

Wet-strength paper offers superior durability and resistance to moisture, making it ideal for printing and packaging applications where exposure to water or humidity is common. Regular paper lacks this enhanced resilience, leading to potential weakening, tearing, or smudging during printing or handling in damp conditions. For packaging, wet-strength paper ensures structural integrity, maintaining print clarity and strength, especially in food packaging, labels, and outdoor materials.

Choosing the Right Paper for Your Needs

Wet-strength paper offers enhanced durability and resistance to moisture, making it ideal for packaging, labels, and documents exposed to water or humidity. Regular paper lacks this reinforcement, leading to weakening or disintegration when wet, suitable primarily for everyday printing and writing tasks. Selecting the right paper depends on the intended use, with wet-strength paper providing reliability in damp conditions and regular paper being cost-effective for dry environments.

Wet-strength paper vs Regular paper Infographic

materialdif.com

materialdif.com