Kraft paper is known for its superior strength and durability, making it ideal for packaging and heavy-duty applications, while sulfite paper offers a smoother surface, better suited for printing and writing purposes. Kraft paper is produced using the kraft process, which removes lignin and enhances fiber strength, whereas sulfite paper is made through the sulfite process that results in a softer, more refined texture. Choosing between kraft and sulfite paper depends on the specific requirements of strength versus surface quality in the intended use.

Table of Comparison

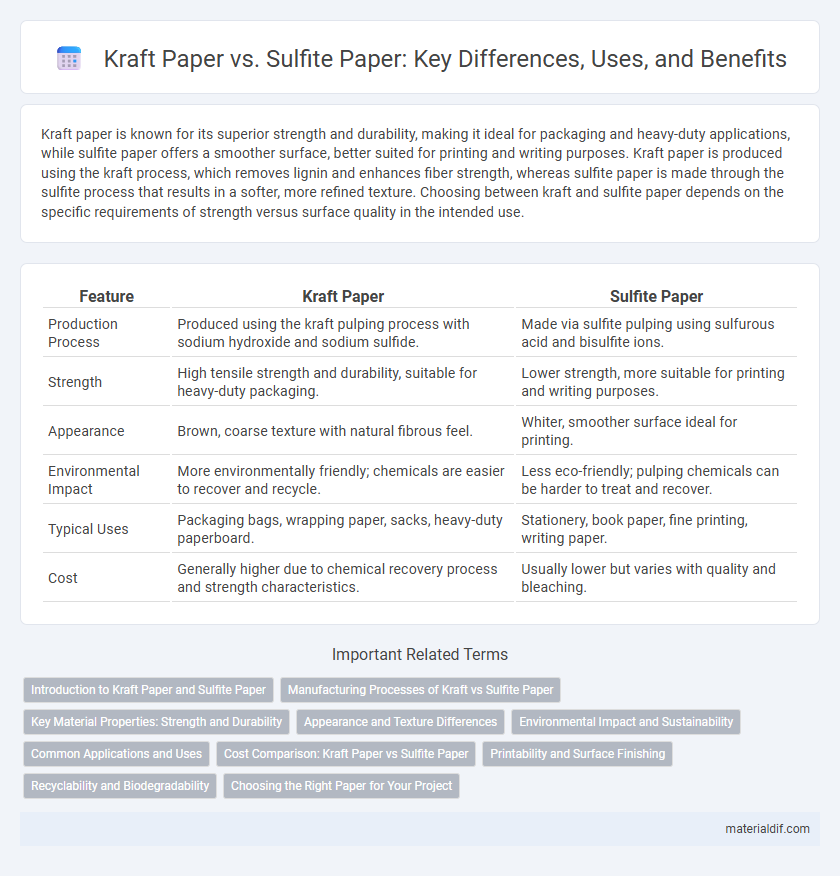

| Feature | Kraft Paper | Sulfite Paper |

|---|---|---|

| Production Process | Produced using the kraft pulping process with sodium hydroxide and sodium sulfide. | Made via sulfite pulping using sulfurous acid and bisulfite ions. |

| Strength | High tensile strength and durability, suitable for heavy-duty packaging. | Lower strength, more suitable for printing and writing purposes. |

| Appearance | Brown, coarse texture with natural fibrous feel. | Whiter, smoother surface ideal for printing. |

| Environmental Impact | More environmentally friendly; chemicals are easier to recover and recycle. | Less eco-friendly; pulping chemicals can be harder to treat and recover. |

| Typical Uses | Packaging bags, wrapping paper, sacks, heavy-duty paperboard. | Stationery, book paper, fine printing, writing paper. |

| Cost | Generally higher due to chemical recovery process and strength characteristics. | Usually lower but varies with quality and bleaching. |

Introduction to Kraft Paper and Sulfite Paper

Kraft paper is produced using the kraft process, which involves the chemical pulping of wood chips, resulting in a strong, coarse paper ideal for packaging and industrial applications. Sulfite paper is made through the sulfite pulping method, yielding a softer, more flexible pulp commonly used for wrapping, printing, and fine paper products. Both papers differ significantly in strength, texture, and production chemicals, influencing their suitability for specific uses.

Manufacturing Processes of Kraft vs Sulfite Paper

Kraft paper is produced through the kraft process, which uses sodium hydroxide and sodium sulfide to chemically convert wood chips into pulp, resulting in stronger fibers and higher durability. Sulfite paper manufacturing involves the sulfite pulping process, where wood chips are cooked with sulfurous acid and bisulfite ions, producing a pulp that is easier to bleach but generally weaker than kraft pulp. The kraft process dominates industries requiring robust paper products due to its ability to preserve cellulose quality and yield high-strength paper, whereas sulfite pulping is favored for fine paper production with superior brightness and printability.

Key Material Properties: Strength and Durability

Kraft paper exhibits superior tensile strength and tear resistance due to its longer wood fibers and chemical processing method, making it ideal for heavy-duty packaging and industrial use. Sulfite paper, while smoother and less prone to discoloration, offers moderate strength but lower durability compared to kraft paper, limiting its application to lighter packaging and printing tasks. The high lignin content in kraft paper enhances moisture resistance and longevity, outperforming sulfite paper in strength retention under humid conditions.

Appearance and Texture Differences

Kraft paper exhibits a coarse texture with a natural brown color due to its unbleached fibers, providing a rugged and sturdy appearance ideal for heavy-duty packaging. Sulfite paper features a smoother surface and a lighter, often white or cream color, resulting from chemical pulping and bleaching processes that enhance its visual appeal for printing and writing applications. The distinct textures and colors of kraft and sulfite papers directly influence their suitability for different industrial and commercial uses.

Environmental Impact and Sustainability

Kraft paper is produced using the kraft process, which involves chemical pulping that yields stronger fibers and higher durability, making it more recyclable and biodegradable compared to sulfite paper. Sulfite paper, derived from the sulfite pulping method, typically contains more chemicals and has a lower yield, leading to greater environmental impact through higher energy consumption and water pollution. From a sustainability perspective, kraft paper's production process is considered more eco-friendly due to its ability to recycle black liquor byproducts and reduced waste generation.

Common Applications and Uses

Kraft paper is widely used for packaging, grocery bags, and wrapping due to its high strength and durability, making it ideal for heavy-duty applications. Sulfite paper, known for its smooth surface and excellent printing quality, is commonly utilized in book printing, stationery, and high-quality paper products. Both types serve distinct roles in industries depending on their physical properties and production methods.

Cost Comparison: Kraft Paper vs Sulfite Paper

Kraft paper generally costs more than sulfite paper due to its higher strength and durability, making it suitable for heavy-duty packaging applications. Sulfite paper is less expensive and commonly used for lighter products, offering adequate performance at a lower price point. Cost efficiency depends on the specific use case, where kraft paper's robustness justifies its premium for demanding environments.

Printability and Surface Finishing

Kraft paper offers superior printability due to its coarse fibers and natural brown tone, providing excellent ink absorption and durability in packaging applications. Sulfite paper features a smoother surface and higher brightness, enabling sharper, more vibrant print details ideal for high-quality graphic finishes. Surface finishing on kraft paper typically emphasizes strength and texture, while sulfite paper supports glossy or matte coatings to enhance visual appeal.

Recyclability and Biodegradability

Kraft paper offers superior recyclability due to its high fiber strength and minimal chemical additives, enabling repeated recycling without significant quality loss. Sulfite paper, while biodegradable, has lower recyclability because its fibers are more easily degraded during processing. Both papers biodegrade naturally, but kraft's robust fiber structure often leads to slower decomposition compared to the faster breakdown of sulfite paper in composting environments.

Choosing the Right Paper for Your Project

Kraft paper offers superior strength and durability due to its long fiber content, making it ideal for packaging and wrapping heavy or abrasive items. In contrast, sulfite paper provides a smoother surface and higher brightness, suitable for printing and writing tasks where clarity and finish are essential. Selecting the right paper depends on project requirements such as tear resistance for Kraft paper or print quality for sulfite paper.

Kraft Paper vs Sulfite Paper Infographic

materialdif.com

materialdif.com