Microperforation creates tiny, precise holes in paper, enhancing breathability and allowing easy tearing without compromising structural integrity. Die-cutting involves cutting specific shapes or patterns with a sharp blade, offering clean edges and customizable designs but lacking the subtle ventilation benefits of microperforation. Choosing between these techniques depends on whether tearability and airflow or intricate shapes and clean edges are prioritized in paper applications.

Table of Comparison

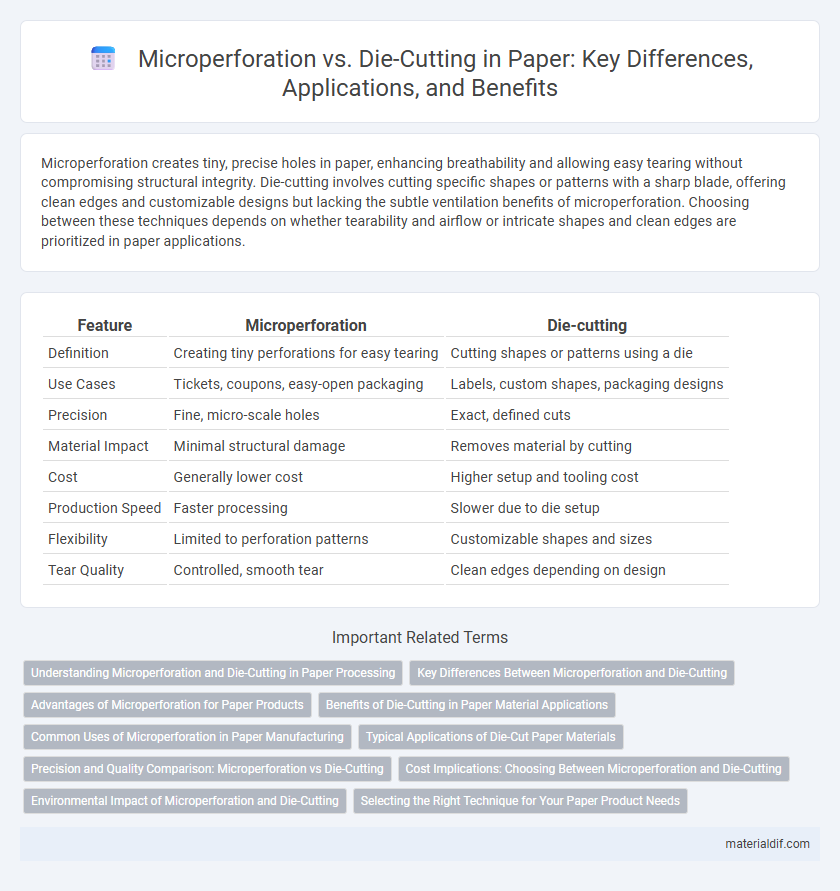

| Feature | Microperforation | Die-cutting |

|---|---|---|

| Definition | Creating tiny perforations for easy tearing | Cutting shapes or patterns using a die |

| Use Cases | Tickets, coupons, easy-open packaging | Labels, custom shapes, packaging designs |

| Precision | Fine, micro-scale holes | Exact, defined cuts |

| Material Impact | Minimal structural damage | Removes material by cutting |

| Cost | Generally lower cost | Higher setup and tooling cost |

| Production Speed | Faster processing | Slower due to die setup |

| Flexibility | Limited to perforation patterns | Customizable shapes and sizes |

| Tear Quality | Controlled, smooth tear | Clean edges depending on design |

Understanding Microperforation and Die-Cutting in Paper Processing

Microperforation in paper processing involves creating tiny, evenly spaced holes that enhance breathability and flexibility without compromising structural integrity. Die-cutting utilizes precise shaped dies to cut or emboss paper, allowing for complex designs and customized shapes with clean edges. Both techniques optimize paper functionality and aesthetics, but microperforation excels in ventilation applications while die-cutting is preferred for intricate designs and packaging solutions.

Key Differences Between Microperforation and Die-Cutting

Microperforation involves creating tiny holes in paper to improve breathability, tearability, or ease of separation, while die-cutting precisely shapes paper into specific forms or patterns. Microperforation maintains the paper's structural integrity with minimal material removal, whereas die-cutting removes portions of the paper entirely, resulting in distinct cutouts or shapes. Microperforation is ideal for applications requiring controlled tearing or ventilation, whereas die-cutting suits crafting detailed shapes, windows, or layered assemblies.

Advantages of Microperforation for Paper Products

Microperforation enhances paper product functionality by enabling controlled ventilation and moisture regulation, which reduces condensation and increases shelf life for packaging applications. The precise, uniform holes preserve structural integrity better than die-cutting, maintaining strength and resistance to tearing. This technique also allows for easier and cleaner tearing or opening, improving user convenience without compromising product security.

Benefits of Die-Cutting in Paper Material Applications

Die-cutting in paper material applications offers precise, consistent shapes and intricate designs that are difficult to achieve with microperforation. This method enhances production efficiency by enabling faster processing speeds and reducing manual labor requirements. Die-cutting also improves finished product durability and aesthetic appeal, making it ideal for packaging, labeling, and creative paper crafts.

Common Uses of Microperforation in Paper Manufacturing

Microperforation in paper manufacturing is commonly used for producing tearable packaging, labels, and postage stamps due to its ability to create precise, easy-to-tear lines without compromising overall sheet integrity. This technique enhances product functionality by allowing controlled perforations that improve ventilation and moisture control, particularly in food packaging and agricultural applications. Unlike die-cutting, microperforation offers a cost-effective solution for mass production where delicate perforation patterns are required without excess material waste.

Typical Applications of Die-Cut Paper Materials

Die-cut paper materials are commonly used in packaging design, labels, business cards, and custom-shaped promotional materials due to their precise shapes and intricate cut patterns. Industries such as food packaging, cosmetics, and electronics rely on die-cutting for creating inserts, windows, and protective sleeves that enhance product presentation and functionality. The versatility of die-cut paper ensures efficient mass production with consistent quality for both decorative and functional elements.

Precision and Quality Comparison: Microperforation vs Die-Cutting

Microperforation offers superior precision by creating uniform, tiny holes that maintain paper integrity and enhance breathability, ideal for tear-off applications and controlled ventilation. Die-cutting provides versatile shapes and intricate designs but may cause slight paper distortion or rough edges, impacting the overall finish quality. Evaluating microperforation versus die-cutting reveals microperforation as the preferred method for consistent precision and smooth paper texture in delicate operations.

Cost Implications: Choosing Between Microperforation and Die-Cutting

Microperforation typically incurs higher initial setup costs due to specialized machinery but offers lower long-term expenses through reduced waste and faster processing times. Die-cutting involves lower upfront investment, making it cost-effective for smaller production runs, though it may lead to increased material waste and slower throughput. Evaluating production volume and waste management efficiency is essential when deciding between microperforation and die-cutting to optimize overall cost-effectiveness.

Environmental Impact of Microperforation and Die-Cutting

Microperforation significantly reduces material waste compared to die-cutting by creating small, precise holes that minimize paper loss during processing. This technique lowers energy consumption and carbon emissions as it requires less force and fewer materials to achieve functional perforations. Die-cutting, while effective for intricate designs, often results in higher paper waste and increased environmental footprint due to its mechanical nature and greater material removal.

Selecting the Right Technique for Your Paper Product Needs

Microperforation enhances breathability and flexibility by creating tiny, precise holes in the paper, making it ideal for applications like packaging that require ventilation or easy tear lines. Die-cutting offers highly customizable shapes and intricate designs, perfect for decorative elements, product labels, or promotional materials. Choosing between microperforation and die-cutting depends on the functional requirements and aesthetic goals of the paper product, ensuring optimal performance and user experience.

Microperforation vs Die-cutting Infographic

materialdif.com

materialdif.com