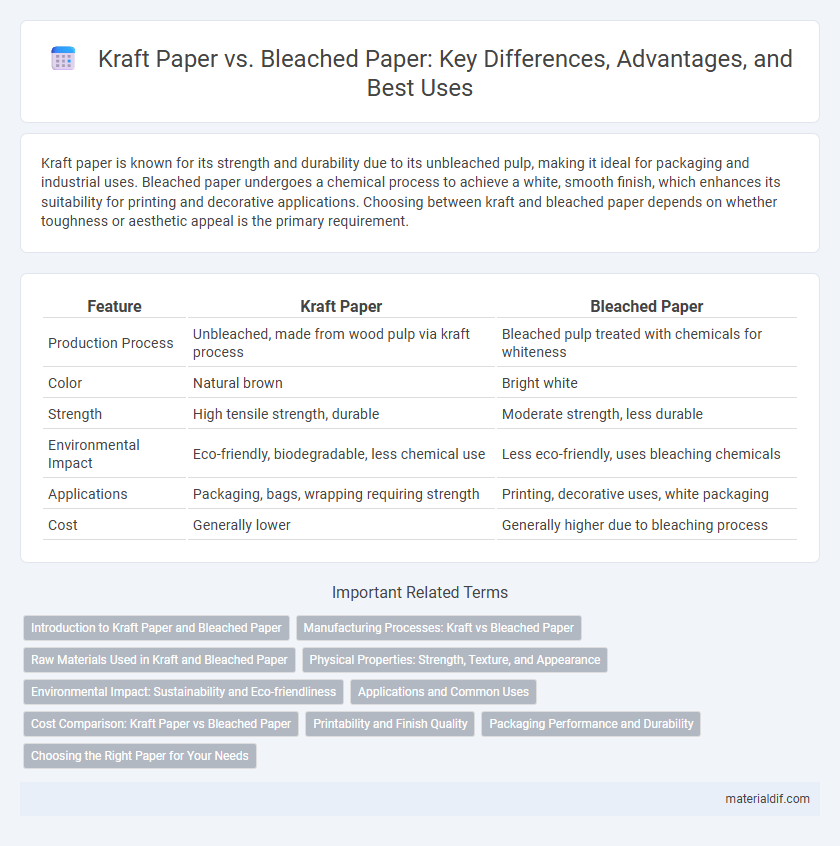

Kraft paper is known for its strength and durability due to its unbleached pulp, making it ideal for packaging and industrial uses. Bleached paper undergoes a chemical process to achieve a white, smooth finish, which enhances its suitability for printing and decorative applications. Choosing between kraft and bleached paper depends on whether toughness or aesthetic appeal is the primary requirement.

Table of Comparison

| Feature | Kraft Paper | Bleached Paper |

|---|---|---|

| Production Process | Unbleached, made from wood pulp via kraft process | Bleached pulp treated with chemicals for whiteness |

| Color | Natural brown | Bright white |

| Strength | High tensile strength, durable | Moderate strength, less durable |

| Environmental Impact | Eco-friendly, biodegradable, less chemical use | Less eco-friendly, uses bleaching chemicals |

| Applications | Packaging, bags, wrapping requiring strength | Printing, decorative uses, white packaging |

| Cost | Generally lower | Generally higher due to bleaching process |

Introduction to Kraft Paper and Bleached Paper

Kraft paper is a strong, coarse paper made from chemical pulp produced through the kraft process, known for its durability and resistance to tearing, commonly used in packaging and industrial applications. Bleached paper undergoes a chemical treatment to remove lignin, resulting in a lighter, smoother, and more aesthetically pleasing surface ideal for printing and writing purposes. The fundamental difference lies in their production processes, where kraft paper retains natural brown fibers, while bleached paper emphasizes whiteness and print quality.

Manufacturing Processes: Kraft vs Bleached Paper

Kraft paper manufacturing involves the kraft pulping process, where wood chips are cooked with sodium hydroxide and sodium sulfide to break down lignin, resulting in strong, coarse fibers that retain natural brown color. Bleached paper undergoes additional chemical treatments, typically chlorine or oxygen bleaching, to remove lignin and brighten the pulp, producing a white, smooth finish suitable for printing. The kraft process is more environmentally friendly due to chemical recovery systems, whereas bleaching increases chemical use and potential environmental impact.

Raw Materials Used in Kraft and Bleached Paper

Kraft paper is primarily made from wood pulp obtained through the kraft process, which uses softwood and hardwood fibers and employs chemicals like sodium hydroxide and sodium sulfide to break down lignin, resulting in stronger, unbleached fibers. Bleached paper typically starts with similar wood pulp but undergoes additional chemical treatments, often chlorine-based or oxygen-based bleaching agents, to remove lignin and whiten the fibers for a cleaner appearance. The raw material differences and processing methods significantly influence the environmental impact, strength, and color quality of the final paper products.

Physical Properties: Strength, Texture, and Appearance

Kraft paper exhibits superior strength due to its unbleached, coarse fibers, providing excellent tear resistance and durability compared to bleached paper. Its texture is rougher and more fibrous, offering a natural, rustic appearance, while bleached paper features a smoother, softer surface and a brighter, whiter look due to chemical processing. These physical properties make kraft paper ideal for packaging and industrial uses, whereas bleached paper suits applications requiring a clean, refined aesthetic.

Environmental Impact: Sustainability and Eco-friendliness

Kraft paper, produced from natural wood pulp with minimal chemical processing, offers superior sustainability due to its biodegradability and recyclability, reducing landfill waste and carbon footprint. Bleached paper undergoes intensive chemical treatments involving chlorine, resulting in higher environmental pollution and slower decomposition rates. The eco-friendliness of Kraft paper positions it as a preferred choice for packaging and printing industries seeking to minimize ecological impact.

Applications and Common Uses

Kraft paper's durability and high tear resistance make it ideal for packaging, wrapping, and industrial use, particularly in shipping heavy or abrasive items. Bleached paper, with its smooth, white surface, is commonly used in printing, food packaging, and arts and crafts where aesthetics and print quality are important. Both types serve specific purposes: kraft paper excels in protective and structural applications, while bleached paper is preferred for presentation and consumer-facing products.

Cost Comparison: Kraft Paper vs Bleached Paper

Kraft paper typically costs less than bleached paper due to its simpler production process that avoids chemical bleaching, reducing manufacturing expenses. Bleached paper requires additional chemical treatments and higher energy consumption, increasing its overall cost. For businesses prioritizing budget efficiency, kraft paper offers a more economical option without significant compromise on strength and durability.

Printability and Finish Quality

Kraft paper offers superior printability due to its coarse texture and high absorbency, which enhances ink adhesion and vibrancy. Bleached paper provides a smoother finish, resulting in sharper image reproduction and more consistent color accuracy. The choice between kraft and bleached paper significantly impacts print quality, with kraft favored for rustic designs and bleached preferred for professional-grade graphics.

Packaging Performance and Durability

Kraft paper offers superior packaging performance and durability due to its high tear resistance and strength, making it ideal for heavy-duty applications. Bleached paper provides a smoother, cleaner surface suitable for aesthetic packaging but tends to be less durable under rough handling or moisture exposure. The unbleached fibers in Kraft paper maintain their natural resilience, enhancing its ability to protect contents during shipping and storage.

Choosing the Right Paper for Your Needs

Kraft paper offers superior strength and durability due to its unbleached fibers, making it ideal for heavy-duty packaging and eco-friendly applications. Bleached paper provides a smoother, cleaner surface and higher brightness, preferred for printing, crafts, and presentations requiring a professional appearance. Assess your project's requirements for toughness or aesthetics to select between the natural robustness of kraft paper and the refined finish of bleached paper.

Kraft paper vs Bleached paper Infographic

materialdif.com

materialdif.com