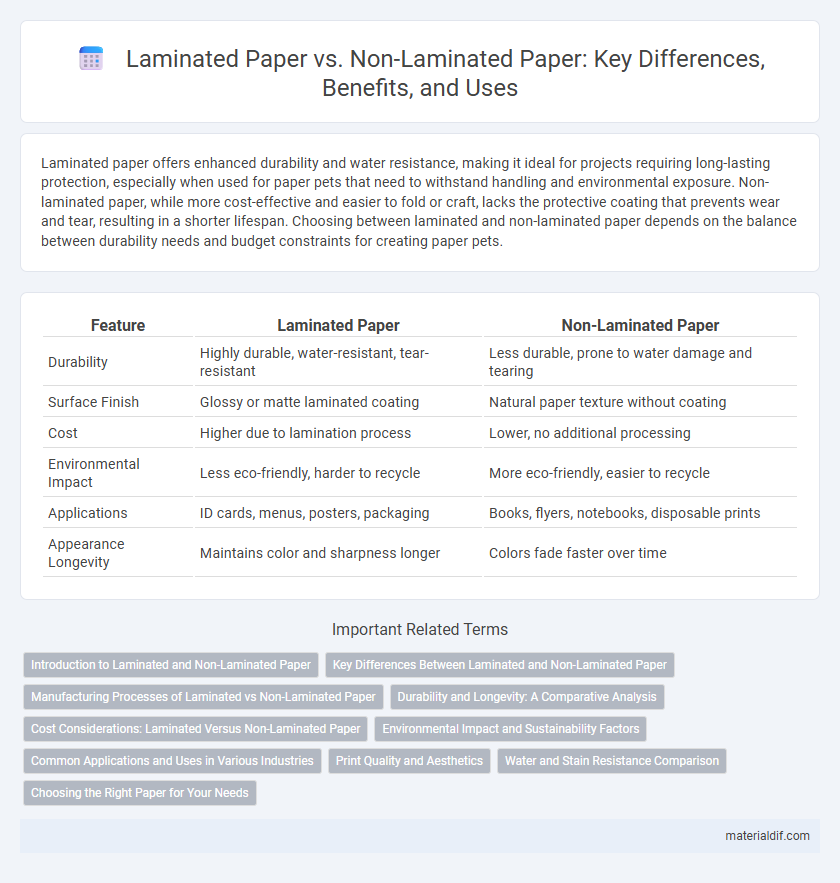

Laminated paper offers enhanced durability and water resistance, making it ideal for projects requiring long-lasting protection, especially when used for paper pets that need to withstand handling and environmental exposure. Non-laminated paper, while more cost-effective and easier to fold or craft, lacks the protective coating that prevents wear and tear, resulting in a shorter lifespan. Choosing between laminated and non-laminated paper depends on the balance between durability needs and budget constraints for creating paper pets.

Table of Comparison

| Feature | Laminated Paper | Non-Laminated Paper |

|---|---|---|

| Durability | Highly durable, water-resistant, tear-resistant | Less durable, prone to water damage and tearing |

| Surface Finish | Glossy or matte laminated coating | Natural paper texture without coating |

| Cost | Higher due to lamination process | Lower, no additional processing |

| Environmental Impact | Less eco-friendly, harder to recycle | More eco-friendly, easier to recycle |

| Applications | ID cards, menus, posters, packaging | Books, flyers, notebooks, disposable prints |

| Appearance Longevity | Maintains color and sharpness longer | Colors fade faster over time |

Introduction to Laminated and Non-Laminated Paper

Laminated paper is coated with a thin plastic film that enhances durability, water resistance, and protection against smudging or tearing, making it ideal for menus, book covers, and signage. Non-laminated paper remains untreated, offering a natural texture and matte finish preferred for writing, printing, and applications where recyclability is prioritized. Choosing between laminated and non-laminated paper depends on factors like intended use, environmental impact, and desired aesthetic quality.

Key Differences Between Laminated and Non-Laminated Paper

Laminated paper features a protective plastic coating that enhances durability, water resistance, and tear resistance, making it ideal for frequently handled documents and outdoor use. Non-laminated paper lacks this additional layer, resulting in lower resistance to moisture and wear but offering greater recyclability and lower production costs. The key differences lie in their protection levels, environmental impact, and suitability for specific applications such as menus, signage, or book covers.

Manufacturing Processes of Laminated vs Non-Laminated Paper

Laminated paper manufacturing involves applying a thin plastic film or adhesive layer to paper sheets through heat or pressure to enhance durability, moisture resistance, and longevity, whereas non-laminated paper undergoes standard pulping, pressing, and drying processes without additional coating. The lamination process typically employs extrusion, cold lamination, or thermal bonding techniques, which add cost and complexity but improve physical properties. Non-laminated paper production focuses on fiber selection, refining, and calendaring for smoothness and printability, prioritizing cost efficiency and recyclability over durability.

Durability and Longevity: A Comparative Analysis

Laminated paper offers superior durability and longevity compared to non-laminated paper due to its protective plastic coating that resists moisture, tearing, and fading. Non-laminated paper is more prone to wear and damage from environmental factors, making it less suitable for long-term use or handling. The enhanced resilience of laminated paper makes it ideal for documents or materials requiring extended preservation and frequent use.

Cost Considerations: Laminated Versus Non-Laminated Paper

Laminated paper typically incurs higher upfront costs due to the additional materials and processing involved in the lamination layer, which enhances durability and water resistance. Non-laminated paper is generally more cost-effective for short-term or disposable applications but may require frequent replacement due to its lower durability. Budget decisions should weigh the long-term savings from reduced wear on laminated paper against the initial expense difference compared to non-laminated options.

Environmental Impact and Sustainability Factors

Laminated paper combines layers of plastic film with paper, significantly reducing its recyclability and increasing landfill waste due to the difficulty of separating materials. Non-laminated paper, being more easily recycled and biodegradable, presents a more sustainable option, minimizing environmental impact through lower carbon footprint and enhanced compostability. Choosing non-laminated paper supports circular economy practices and reduces pollution associated with plastic production and disposal.

Common Applications and Uses in Various Industries

Laminated paper offers enhanced durability and moisture resistance, making it ideal for packaging in the food and beverage industry, as well as for creating long-lasting printed materials like menus and maps. Non-laminated paper, valued for its recyclability and cost-effectiveness, is commonly used in printing newspapers, office documents, and promotional flyers across various sectors. Both types serve specific roles depending on the required durability, aesthetic quality, and environmental considerations within industries such as retail, education, and marketing.

Print Quality and Aesthetics

Laminated paper enhances print quality by providing a smooth, glossy surface that intensifies colors and sharpens images, making prints more vibrant and visually appealing. Non-laminated paper tends to absorb ink more, resulting in softer, less vivid colors and a matte finish that can appear more natural but less striking. The lamination also adds a protective layer that prevents smudging and fading, preserving the aesthetic quality of printed materials over time.

Water and Stain Resistance Comparison

Laminated paper offers superior water and stain resistance due to its protective plastic coating, preventing liquid absorption and surface damage. Non-laminated paper absorbs moisture quickly, leading to warping, staining, and reduced durability in wet conditions. For applications requiring moisture protection or frequent handling, laminated paper provides enhanced longevity and cleanliness compared to non-laminated options.

Choosing the Right Paper for Your Needs

Laminated paper offers enhanced durability and moisture resistance, making it ideal for documents exposed to frequent handling or environmental factors. Non-laminated paper provides a cost-effective solution suitable for temporary use or materials requiring easy annotation and recycling. Selecting the right paper depends on the balance between durability needs and budget constraints specific to the intended application.

Laminated Paper vs Non-Laminated Paper Infographic

materialdif.com

materialdif.com